Sure thing.

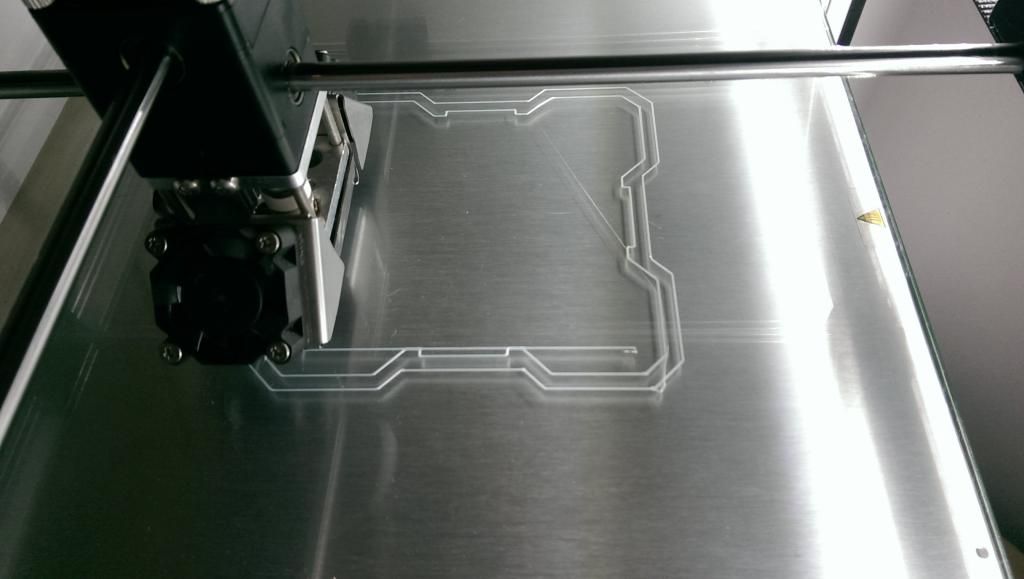

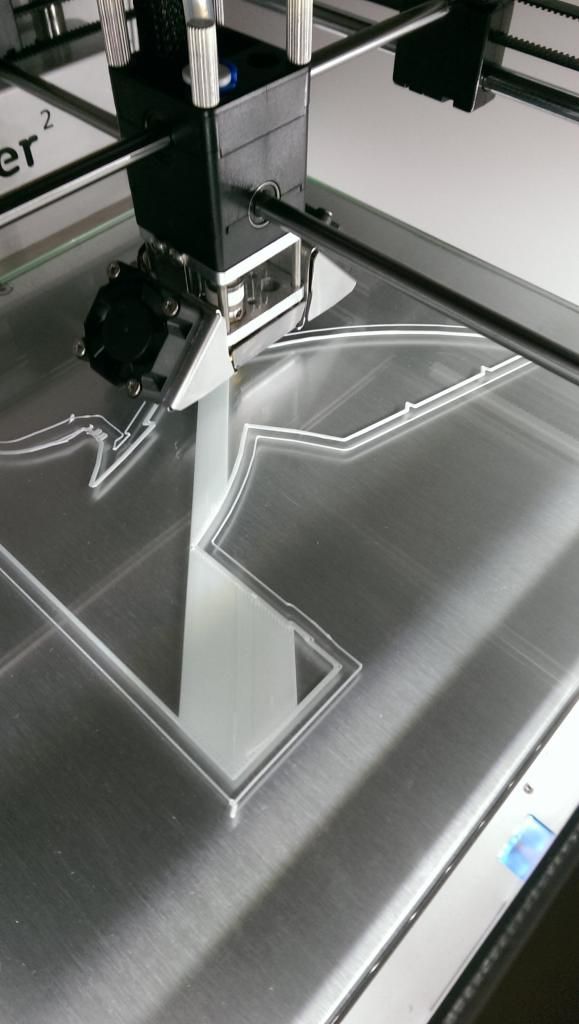

The paper method used to work great, but I eventually started printing out a large square, adjusting until good, abort and then printing after that, but whenever I started a new print it would need adjusting again for some reason.

Dont know if relevant, but I am using Robert's alternative feeder and recently changed my rear fan for a new sunon one.

Should be noted these mods were done after the jamming problem to see if they would help.

Recommended Posts

gr5 2,210

Excellent.

At some point (probably now) you should probably stop using the leveling procedure. I haven't used it for about a year now. I just make small adjustments (quarter turn typically) with the 3 knobs (usually same amount on all 3) and eventually I got it perfect.

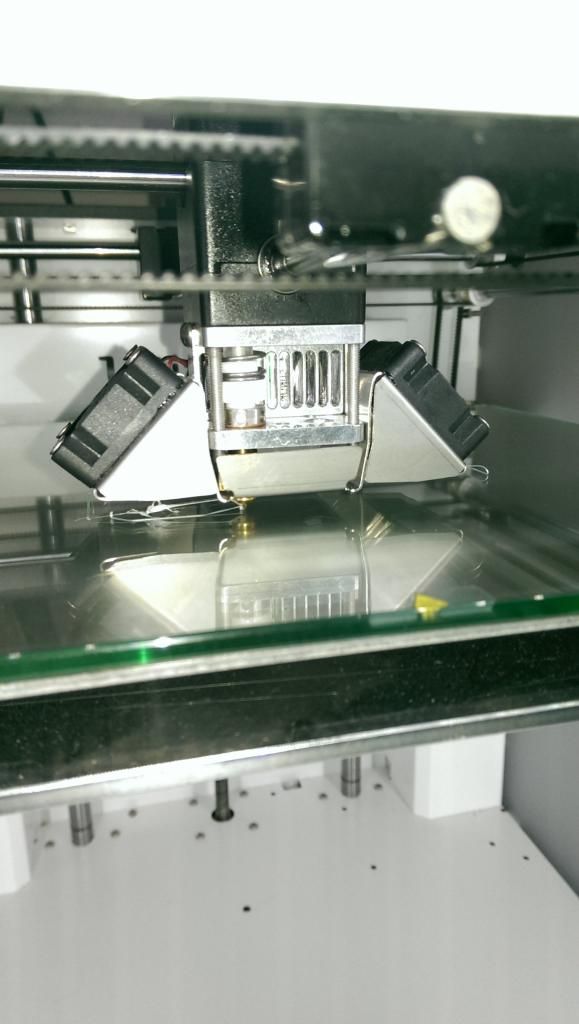

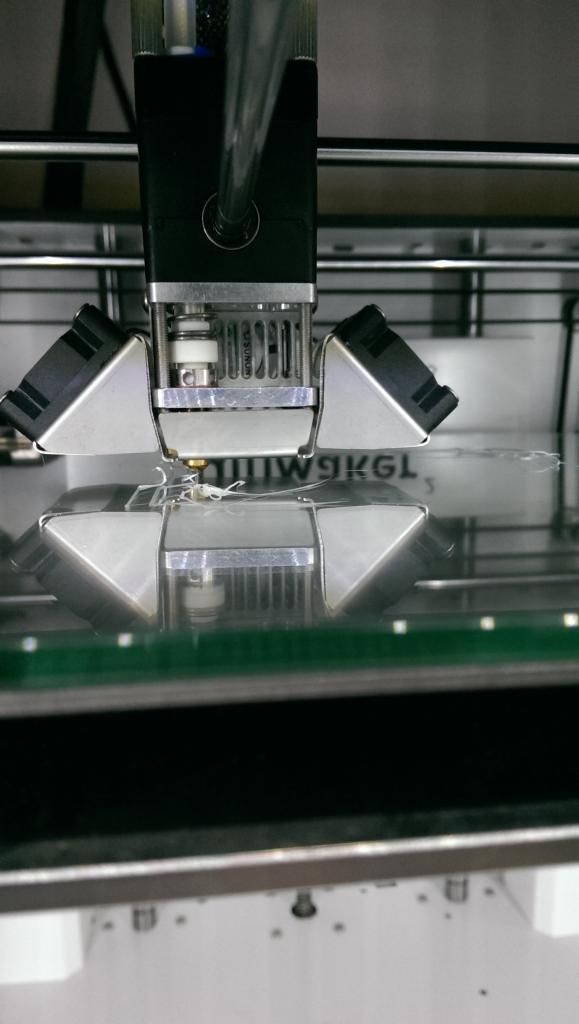

bunching up around the hot end 90% of the time indicates you have too much space between the nozzle and hot end but I'd like to see a picture. Or alternatively it's not extruding enough at first either because a retraction occurred, an extruder skip occurred (both normal and in both cases they recover after after about 30mm in printing) or due to underextrusion. To test for underextrusion print even slower (.3mm is 3X the volume as .1mm so try even slower bottom layer just to see - slow feedrate to 50%).

So one possibility is that it is still slightly clogged. Perhaps a 25% blockage. If slowing to 50% feedrate fixes it then assume you have partial clog. If instead it doesn't help and moving glass closer to nozzle fixes it then assume nozzle is fine.

If you conclude nozzle needs more cleaning I recommend you find a wire that fits inside the nozzle hole such as a hypodermic or acupuncture needle.

Link to post

Share on other sites