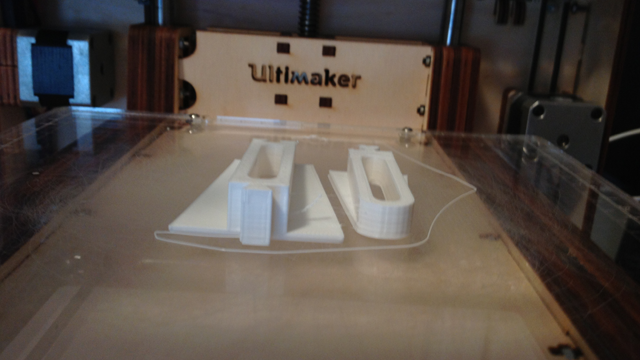

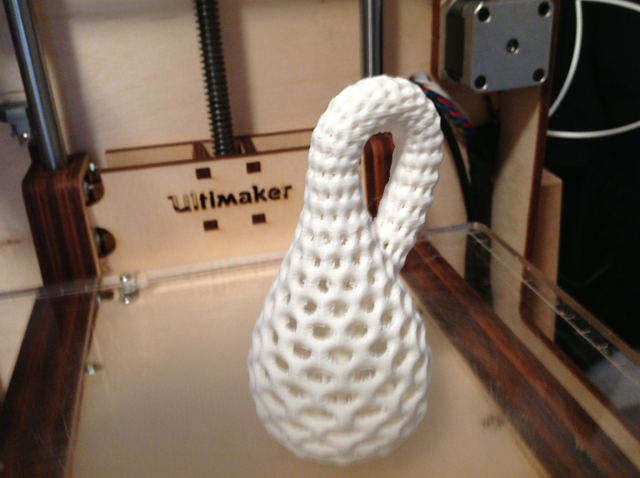

I understand that printing directly to glass isn't recommended, and that it isn't easy to get working, but I refuse to believe it impossible. For example I have successfully done it twice in a row today:

It might not be entirely clear in the images above (pardon my poor camera) but there was little to no warping in the corners (the first layer was very sparse filament wise due to some residual ABS getting in the way). Granted this was a fairly small print which only took 30 minutes to print, but I think it shows that it is possible, at least for small prints. So far with my tests it seems that the print is more successful if there is slightly less filament being extruded than normal for the first few layers. My guess as to why this is is that when there is more filament extruded it's easier for it to stretch and curl up, but that's just speculation. I'm going to try adjusting the start gcode to get more consistent results (I think I'll start each print by retracting a small amount).

For anyone interested my current settings in Cura printing PLA are as follows:

Layer height: 0.2, Wall thickness: 0.6, Print speed: 75, printing temperature: 205, bottom/top thickness: 0.6, fill density: 25, bottom layer speed: 45, travel speed: 130

These settings aren't perfect yet but are consistently working. I have not sanded or done anything special to the platform. Hope this helps others get off their tape dependence someday ![]()

-Mark

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

joergen 2

AFAIK, PLA will not stick to cold glass, and neither will ABS.

The recommended glass surface temperature is very similar to the glass-transition temperature of the plastic you are using: PLA needs about 70C, and ABS 110-120C HBP glass temp.

(In case you care, PLA Tg is 58C)

Link to post

Share on other sites