Hi everyone! Seems that "extruder issues" are many... so, I wish to share my experience:

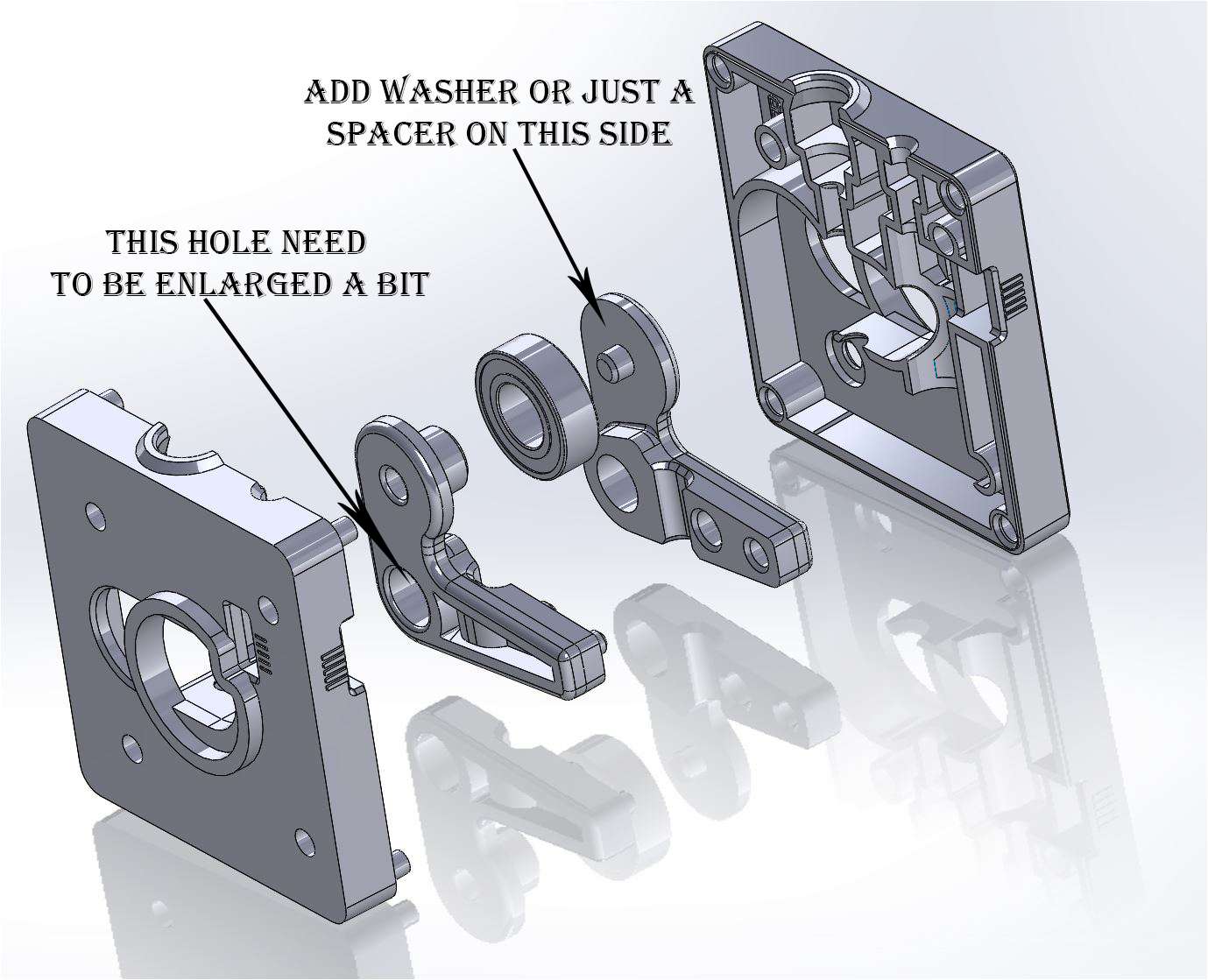

1) before inserting the filament check the feeder, on mine there was a problem about the ball bearing that stuck due to lack of space and issue on pivot point of the lever that hold the ball bearing

2) change the original spool-holder with this one https://www.youmagine.com/designs/low-friction-um2-spoolholder

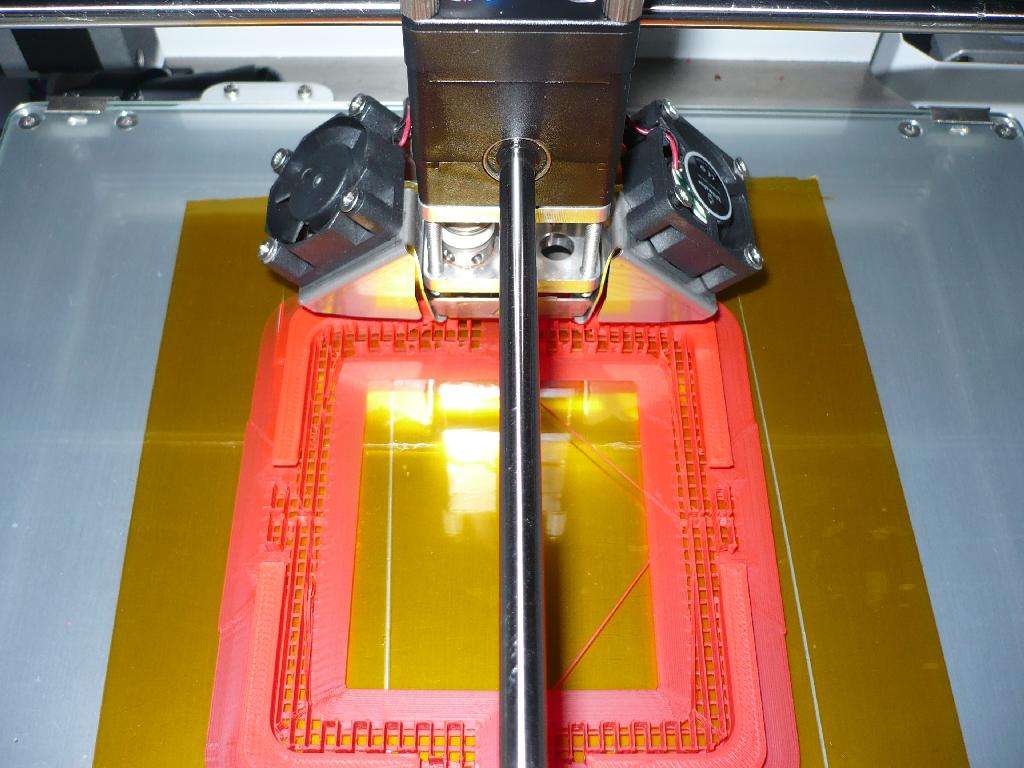

3) if you print with ABS I thought that the best way to clean the hot end is with a PTFE rod that fits inside the hole so you can clean inside without inserting other material that could even worsen the problem ... I made this for that dirty work :

4) always for ABS print, try to flip over the right fan http://imageshack.com/a/img907/6607/5nRvUV.jpg

use some kapton and if you still have adhesion problems clean the kapton with a paper towel wet with acetone.. it will become a little tricky to take off your print when finished ... but it will not unstuck from the bed while printing.....

Have a good print day ![]()

-

1

1

Recommended Posts

gr5 2,210

There are several places for the filament to get stuck along the path - where the bowden ends, where the peek part starts and ends. Usually if you just pull it out a few inches and push it back in it gets past these lips or edges or catches. But to avoid this I always cut the end of my filament to a point before feeding it in.

Link to post

Share on other sites