What you call "a safety feature" I call an issue :)I thought it is just point of view... but a stepper motor that loss step for over charge is not a feature....

Questions: I found that by default the current driving the stepper are all at 1300mA except the one of the feeder that was at 1250, a little difference but why?

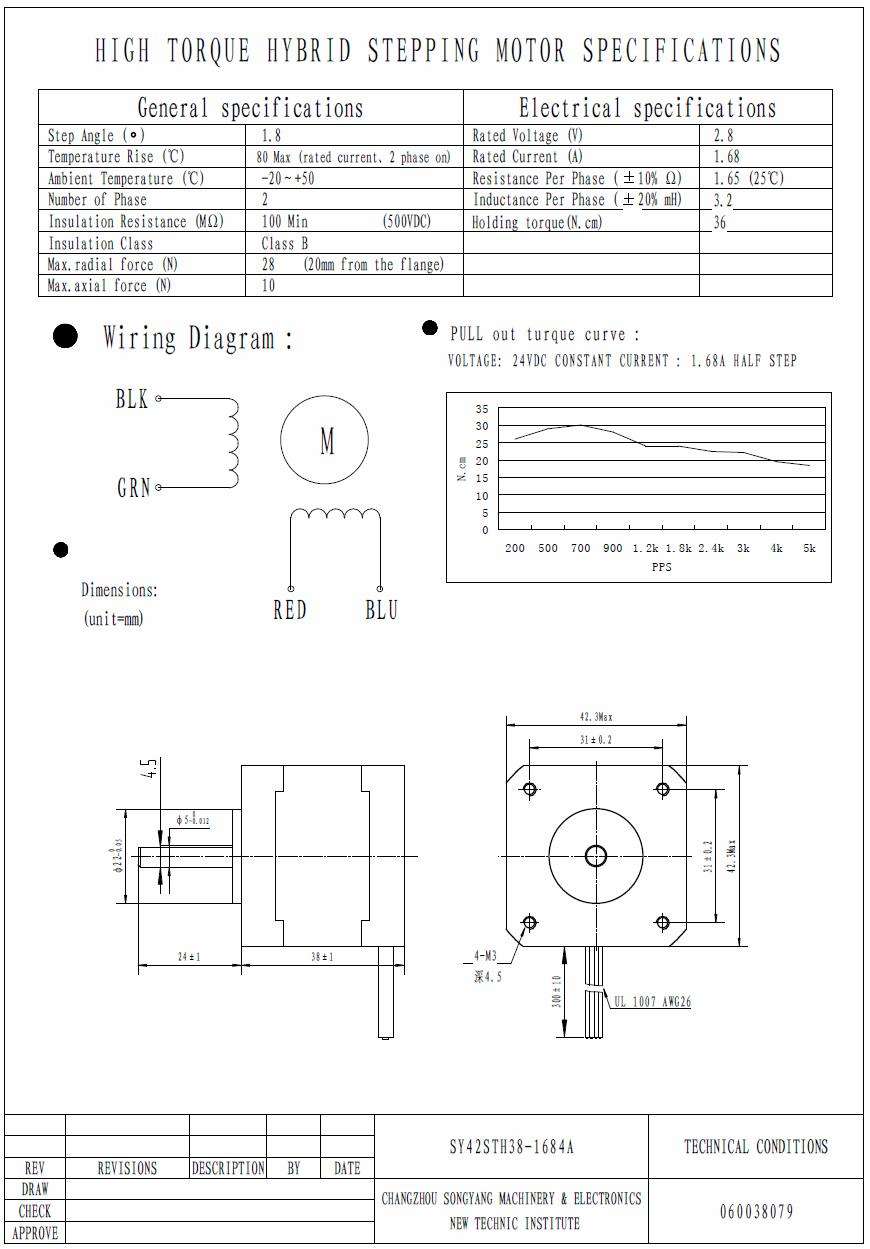

And another question is why this limit to 1300mA when the stepper are rated up to 1680mA?

p.s.: I think that Atomic pull is overestimated... I use a PTFE rod like this

to clean the hot end, so you can leave it clean without addition of other material inside the hot end...

to clean the hot end, so you can leave it clean without addition of other material inside the hot end...

Recommended Posts

Labern 775

This is normal and is a safety feature to stop the feeder motor grinding your filament.

It means that there is to much pressure on your feeder motor. This could be on the roll side like a filament tangle or it can be from pressure build up on the other side of the feeder.

Printing to fast.

blocked nozzle.

damaged bowden tube

deformed PTFE coupler

the list goes on.

I would start with an atomic pull and see how it goes then. after that then look more in depth.

Link to post

Share on other sites