@ultiarjan: ok thx! ![]()

Doh! Sorry, I meant 0.15mm layer height.

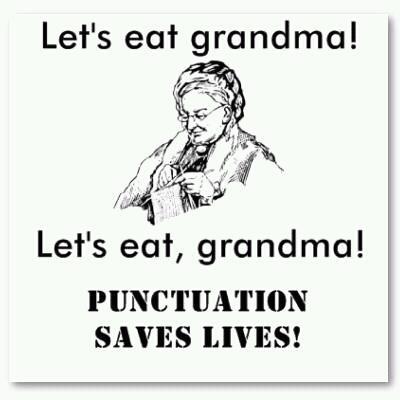

Reminds me of... proper punctuation saves prints ![]()

3

3

Hi!

The same problem again... and again the warping starts at the same location: the right back side (on the left back side and everywhere else everything is fine)

What is different at that specific location? Is it possible that the heat-plate does not work there properly? I stayed awake yesterday till layer 4 was started and there was everything ok...

I also let the door and windows closed so there should not be any airflow...

Is it possible that the heat-plate does not work there properly?

Well, you could check this easily, if you have access to an infrared thermometer...

More likely the buildplate is a tiny bit tilted and therefore the nozzle distance on this corner is a tiny bit too big. Or one of the 6mm rods is bended a tiny bit in this area.

As a test: you can make the "paper" test on all 4 corners, if you move the axis by hand (printer switched off). A helping "third hand" makes it more convenient.

And in general: i suggest to use at least 0.2mm as first layer height and bring the nozzle a bit closer to the buildplate. For example: don't use the paper during the buildplate leveling, let the nozzle directly touch the glass instead.

To be honest: usually i don't level the buildplate that exactly....

I have no interest to promote special products, but proper adhesion became a no brainer for me since i use DimaFix (or 3DLac - if you prefer). I printed parts from PLA that are 220x150mm without a brim and without any adhesion problems. It just works - point.

1

1

Hi!

Thx for the answer! Infrared thermometer is on the wish list but not available for me now ![]()

I tested all 4 corners and i think i recognized a bit more distance on the back, so i made it tighter there (and generally everywhere as you said)...

My initial layer is 0.27mm so this should be ok...

I stated the next try right now and will report back...

As the nozzle is off to one side the RHS fan blows on the glass more then it does on the LHS.

You could set a draft shield close to the print and up 5 - 10mm

I have found it helped on prints that tended to warp.

1

1

@Labern: this sounds interesting! I thought about this before that the right fan will boost the warping effect because once a little bit of the object edge gets lifted the fan blows under it. But how can i practically build a draft shield? A piece of wood? THX!

No it's a feature in Cura.

It is a skirt that prints to a certain height. Not sure where it's located in the menu as I'm not home right now.

1

1

Ah, ok this is the skirt feature for -sorry for the silly question ![]()

I will try this next time. Thx!

It's not skirt but called draft shield. You need to be using Cura 2.* And may have to activate menu option in advanced.

1

1

IT WORKS!!!

Finally, the print gets perfect!!! It was the calibration of the built plate. The tip from tinkergnome to do the calibration without the paper and let the nozzle touch (or nearly touch) the built plate was brilliant!!!

I have to say that the original ultimaker description how to calibrate the built plate is a bit misleading (at least for me)... –I always watched the built plate while i moved the “Ultimaker Calibration Card” under the nozzle to not get pushed down what apparently leads to a to large distance between the nozzle and the plate. Because the plate is fixed on the back side i could not see if it gets pushed down so i tried to get the same paper-shift-resistance-feeling as i get on the front which results in a difference between the front and the back and so it warped only on the back side.

Thx to all for taking the time to help me! The print isn’t finished jet (the printer is doing the last 5mm right now) but if you are interested i will provide photos of the finished chassis.

Best regards!

sepl

Recommended Posts

Nicolinux 288

Hi Sepl

welcome to the forums. Check that your glass plate is level. Take it out, put it on a plane surface and push down on the corners to see if it wobbles.

I found that 3DLac (that's a special spray for better adhesion but it might be just strong hairspray) works really well when something doesn't want to stick.

A bit off-topic - but do you really need to print with 0.06mm layer height? If you push it up to 1.5mm, you'd still get a very smooth surface and will reduce the printing time greatly.

Link to post

Share on other sites

tinkergnome 927

That's suspicious. Perhaps it "warps" because the bottom part of the printed object stays too soft. What's the height of the first layer? Do you use any glue?

It's probably better to reduce the temperature of the heated bed after a few layers.

You can start with 65°C (for a good first layer adhesion) and reduce it to 55° (or even lower) from layer 3 or 4 upwards.

If this makes a difference...? You will know it in - let's say - 7 hours...

Link to post

Share on other sites

ultiarjan 1,223

Nico means 0.15mm

Link to post

Share on other sites

sepl1977 1

Thx so much for your fast replies!

@Nicolinux: i checked the glass plate as you said and it seems to be level, but to be sure i turned it 180° so that the heat-danger sticker is on the rear side (if i have problems now on the front side i have the evildoer

Maybe off-topic but a good point the thing with the layer height! Do you really mean 1.5mm or 0.15mm (like in the “Fast Print” preset)? Off course i do not really need 0.06 for this particular project (i guess this is the classic enthusiastic beginner “mistake” to outbid the new purchased gear .

.

@tinkergnome: in the “Quality” section i let everything default so i guess the first layer is 0.27mm and yes i use glue (the stick which comes with the printer and a bit water). Thx for the hint lowering the heat plate temperature after a few layers.

Ok i will start the next try now with the following adjustments:

Layer Height: 0.15mm (@Nicolinux pls let me know if you really mean 1.5mm but this sounds a bit too “stepie” to me)

Initial Layer Height: 0.27mm

Bed-Temp: 65°C and i will go down after layer 4 to 55°C

THX again for your help! I will let you know how it works out!

best regards!

sepl

Ps: 3DLac is ordered!

Edited by GuestLink to post

Share on other sites