Researched a bit and found:

The Ultimaker 1.5.7 board bases on Arduino Mega plus a Ultimaker shield:

http://reprap.org/wiki/Ultimaker's_v1.5.7_PCB

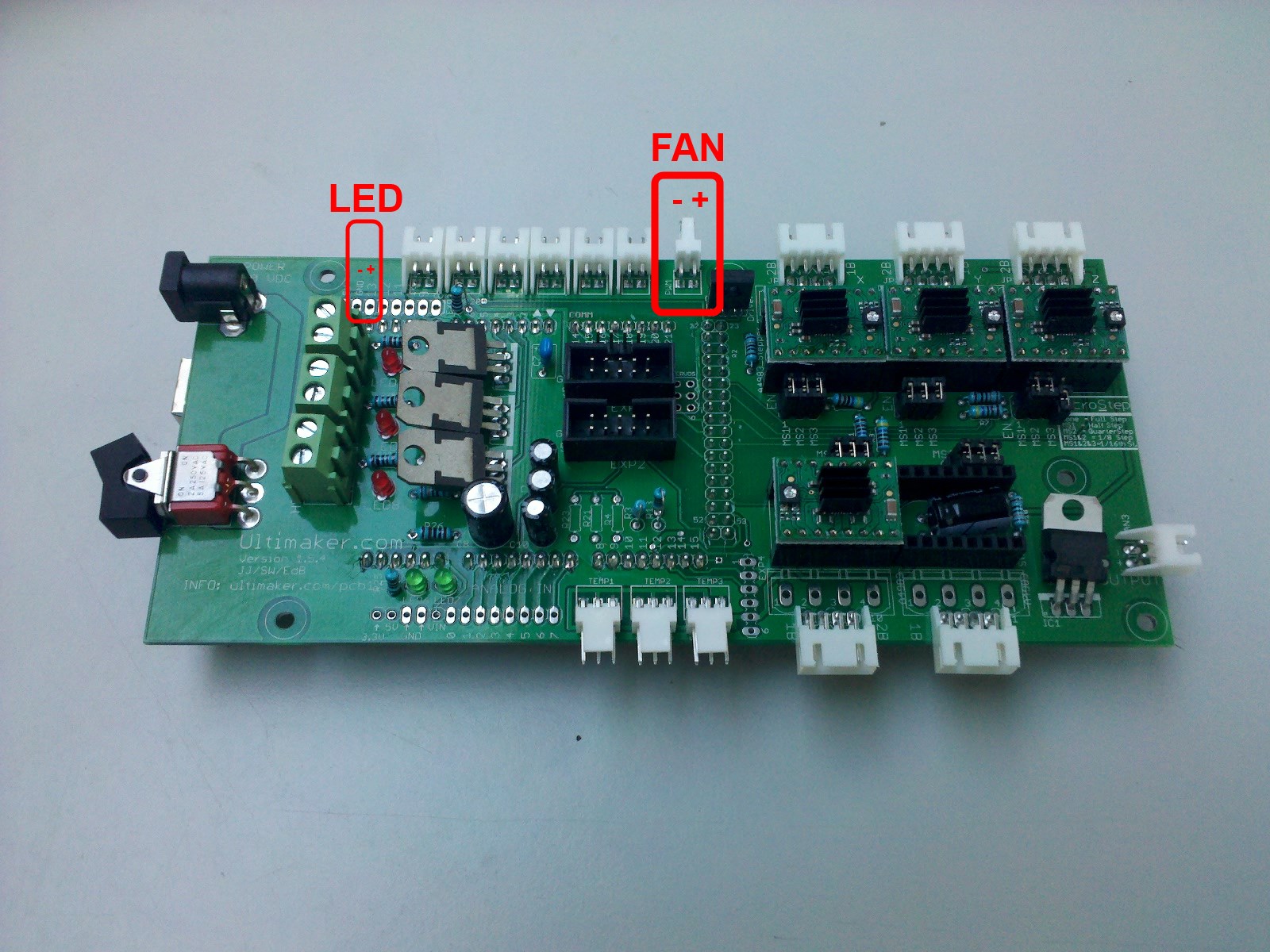

There is only 1 fan connector:

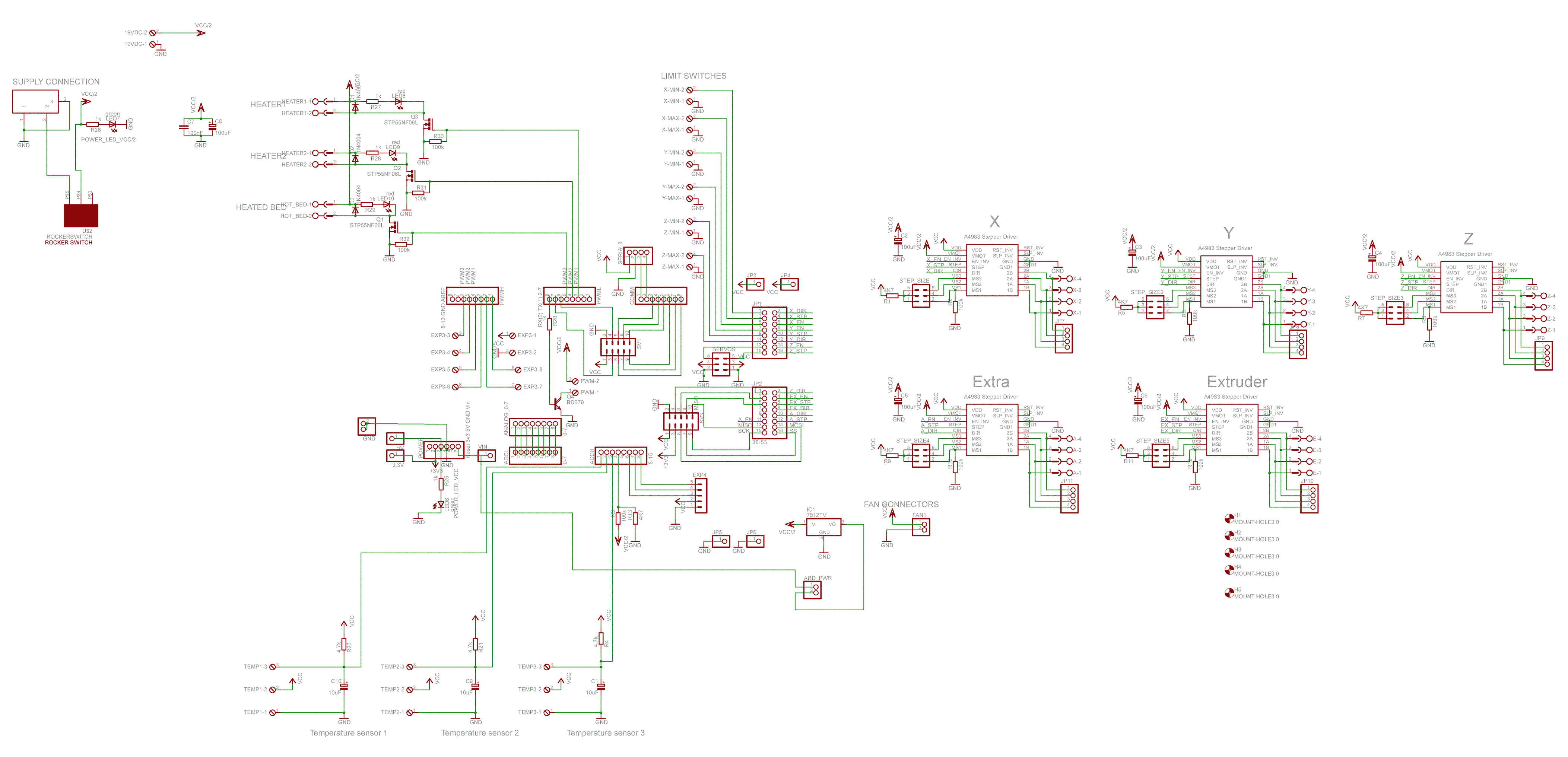

According to this schematic:

and this offer:

https://www.fablabfactory.com/products/ultimaker-fans?variant=50721821907

it uses VCC/2 = 12V.

It is driven off the PWML connector that also serves the heaters.

And in the above schematic you see that a BD679 darlington transistor drives this:

http://www.onsemi.com/pub/Collateral/BD675-D.PDF

The mentioned datasheet says 4A. Which probably refers to the derating diagram which allows 10W of dissipation at 120C.

As you are planning for a 12V fan, you have an output serving that and 0.1A should not be a problem at all.

Other than that, maybe this is what you are looking for:

Recommended Posts

lars86 42

Crickets!!!

Anyone know how these voltage step up/down boards will do with a PWM signal?

Link to post

Share on other sites