Hello Smithy. Sorry to respectfully disagree. There is, e.g., a well known video from Stephan - CNC kitchen talking about line width and its influence on print's characteristics. every nozzle being able to extrude even more than 200% it's size. There is also a plenitude os data and texts. The triad Temperature, Flow and Speed. Just a matter of reaching the balance. Of course there is the limits of the printer, bit I do believe my printer is able to do that.

Example: https://dyzedesign.com/2018/07/3d-print-speed-calculation-find-optimal-speed/ where:

Maximum line width

The maximum line width will depend on your nozzle flat width. Manufacturers should specify this dimension to configure your slicer accordingly. The maximum line flat should be equal to the nozzle flat. Note that any overflow will have an impact on top infill quality, as it will tend to rise around the nozzle.

Considering a 0.40mm nozzle having a 0.80mm flat with a 0.20mm layer thickness have a maximum line width of 1.00mm.

Going bigger!

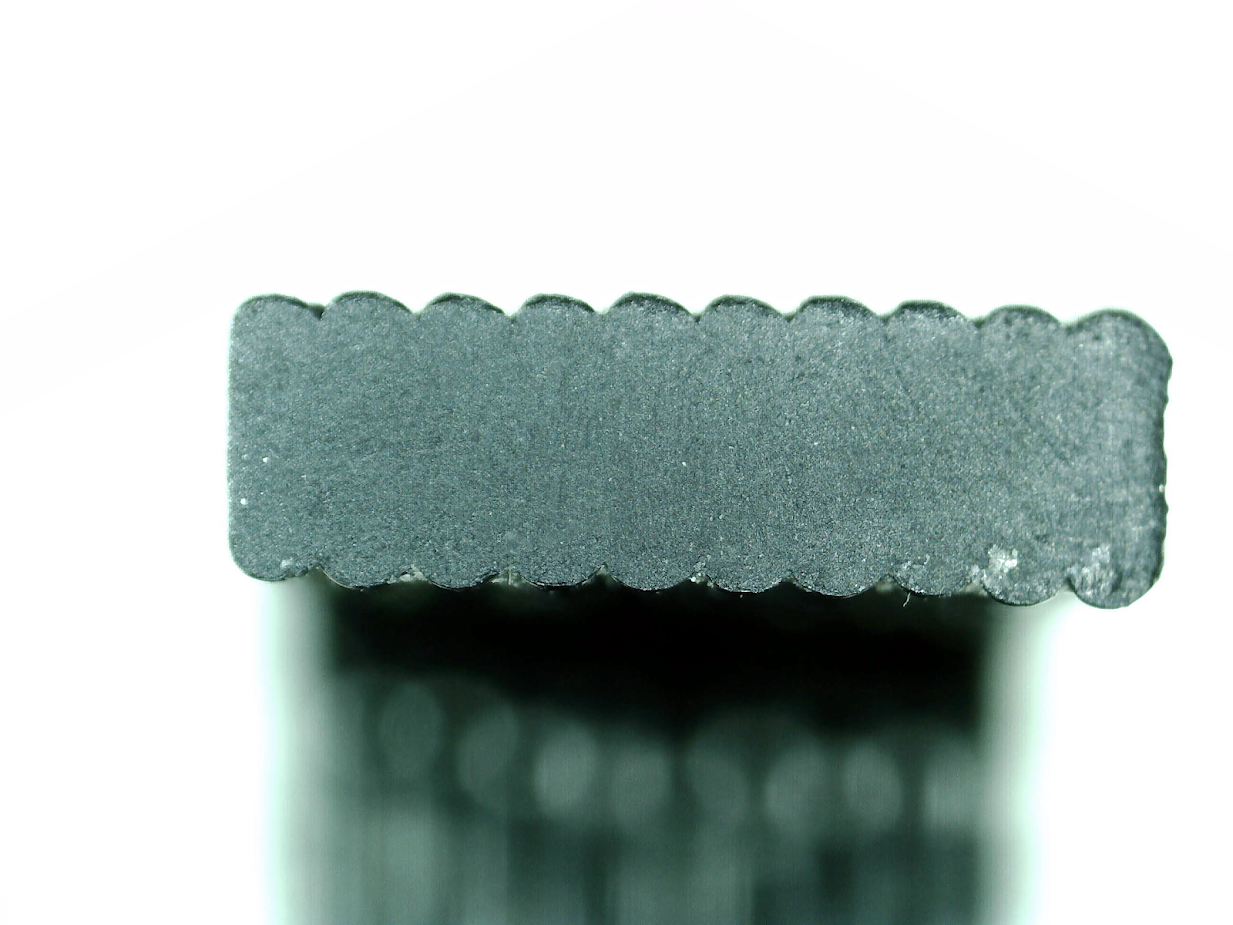

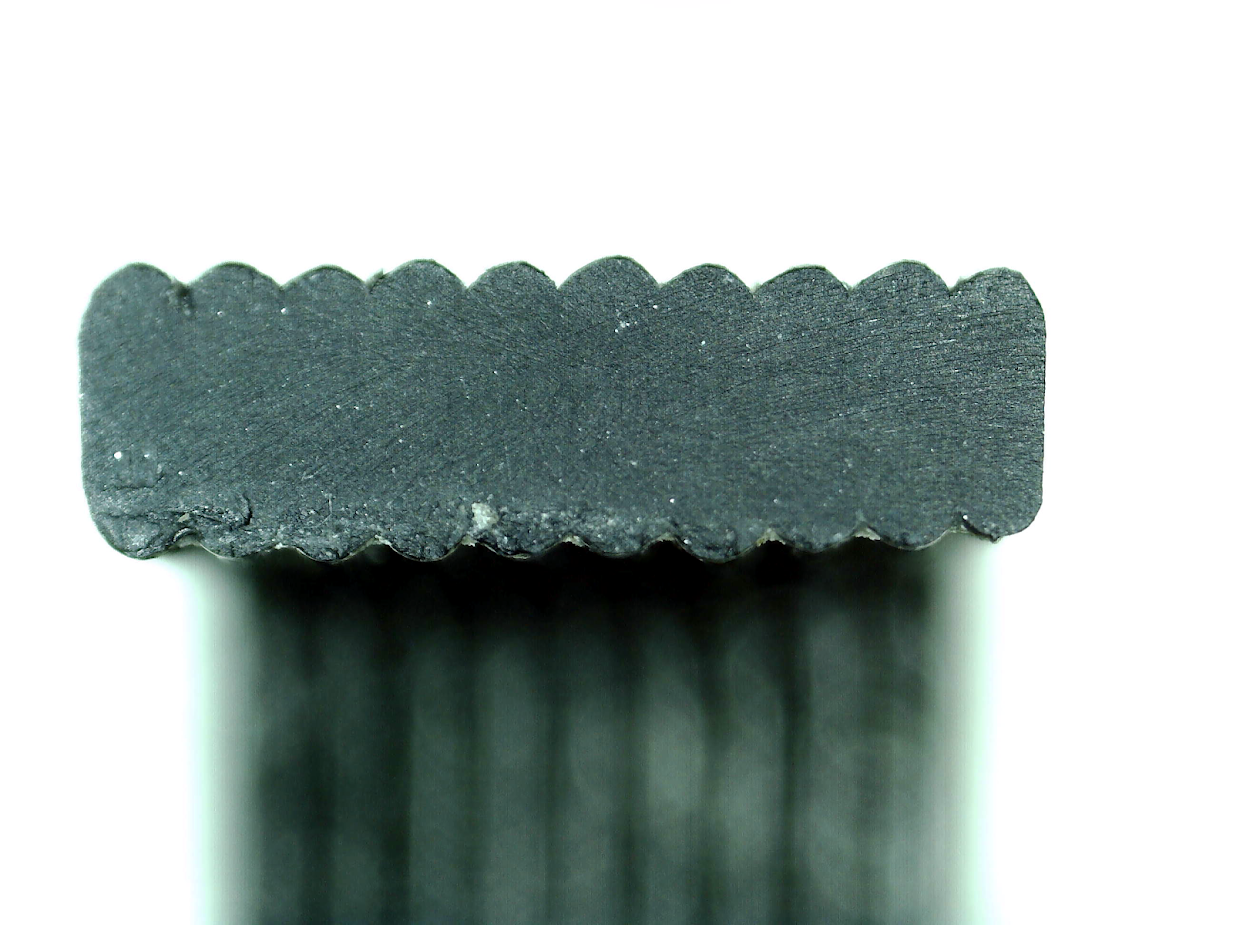

However, nothing is stopping you from going a lot higher or lower. For example, the two images below are the same exact Gcode, one ran with a 1.00mm nozzle, the other with a 0.40mm nozzle. The line height is 0.50mm and line width is 1.50mm.

As you can see, there is barely any difference. As long as the 0.40mm nozzle flat is within the margin, the result is pretty good. In this case, the layer height was 125% the nozzle diameter.

Smaller nozzle can still extrude large lines, but have more flow restrictions compared to larger nozzles. The speed must be decreased to get the same results.

Recommended Posts

Smithy 1,145

When you want to print with line widths like 0.6 or 0.8 you also have to change the nozzle. You cannot print 0.8 line width with a 0.4 nozzle. That's the reason why there are different nozzle sizes available.

Link to post

Share on other sites