I think they are all about the same strength. The youngs modulus is posted for each. The larger the youngs modulus the stiffer the material.

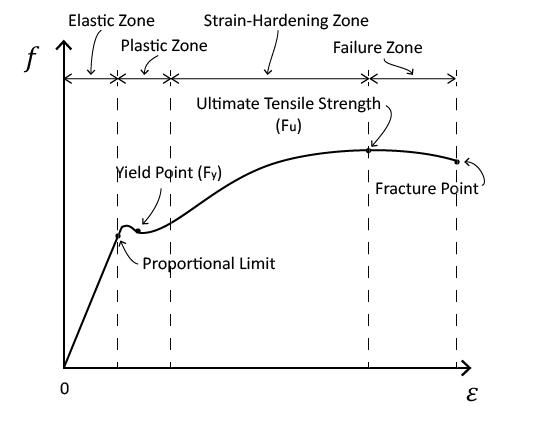

The vertical axis below is the force applied to the material. The horizontal axis is how much the material flexes/bends/stretches (it's all the same thing actually!). In the linear region (elastic zone) the slope is the youngs modulus. Steel has an amazingly steep slope. Rubber the opposite. The ultimate breaking point for ABS, PLA, Nylon (Fu below) is about the same for these 3 materials.

However if you build say a hammer out of nylon you will have one hell of a time breaking it. Because it is flexible you can wack that hammer with all your might and not cause any damage whereas PLA will break. Just because a human can't break it by wacking it doesn't mean you can't break it by applying a slow strong force and like I said - it takes about the same amount of force to break PLA or Nylon.

So if you are building a bridge PLA is probably better because it won't flex so much and is just as strong. If you are building something that shouldn't be breakable by children then Nylon is better because it will bend enough so that it's very hard to break without really serious effort.

Again I think all the taulman's have a similar break point it's just the flexibility and printability that changes. Bridge is the least flexible[edit: wrong! see next post I was thinking about PA6 nylon] (but still too flexible for most of my applications such as a quadcopter) and easiest to print by far (it sticks better, doesn't absorb as much water, can be printed at cooler temps which helps with water issues and bonding issues).

edit: correction - reading the post linked to by didier (which I wrote) nylon is almost twice as strong as PLA's fracture point but really that's not a big difference. I wish I had measured the yield points of these materials (I want to some day) because beyond that point the material is permanently bent into a new position so you really don't want to go over that limit for most applications.

Recommended Posts

DidierKlein 729

If you're interested in strength you might want to have a look at this thread by gr5:

http://umforum.ultimaker.com/index.php?/topic/7575-strength-of-different-filaments/

Link to post

Share on other sites