Also try pushing the head around with power off. See if X and Y axes are obviously different.

Also if you already leveled it once and you want to make the bed closer I recommend simply turning all 3 screws 1/4 turn and not running the procedure. The procedure gets you close but to get it better it's best to just turn the screws and print a skirt or brim.

Recommended Posts

gr5 2,210

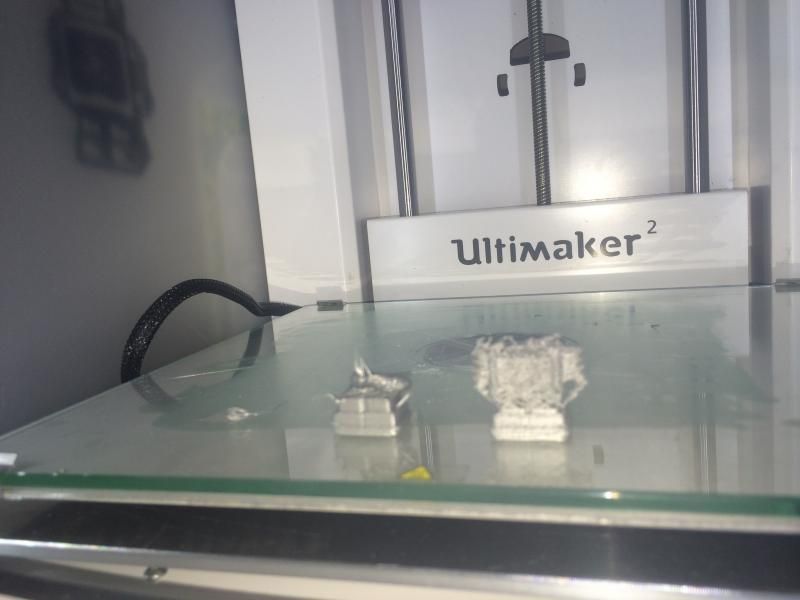

1) UM2 should come assembled. Do you mean you have the UMO+?

2) Can you maybe post a video (with sound)? I don't know what noise you are talking about. If Y axis is slipping it will typically shift between layers. Are you sure it isn't the feeder that's slipping? UM doesn't host video so you have to post it on vimeo, youtube, or similar and then link to it.

Link to post

Share on other sites