Sorry, I thought everyone would have the board memorized!

Sorry, I thought everyone would have the board memorized!

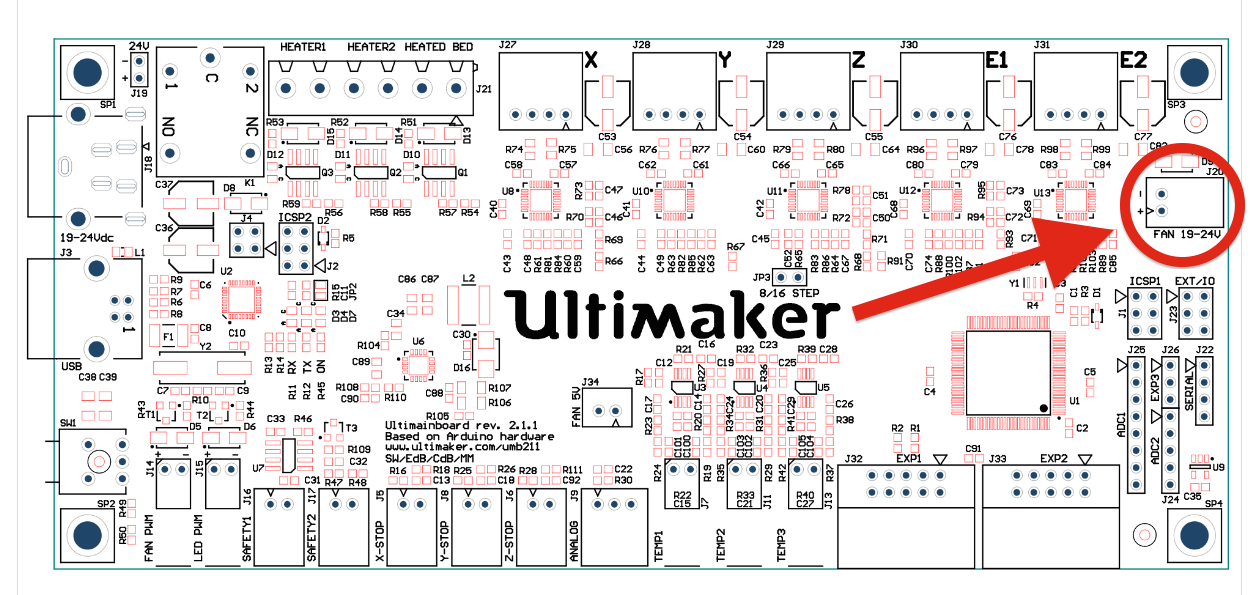

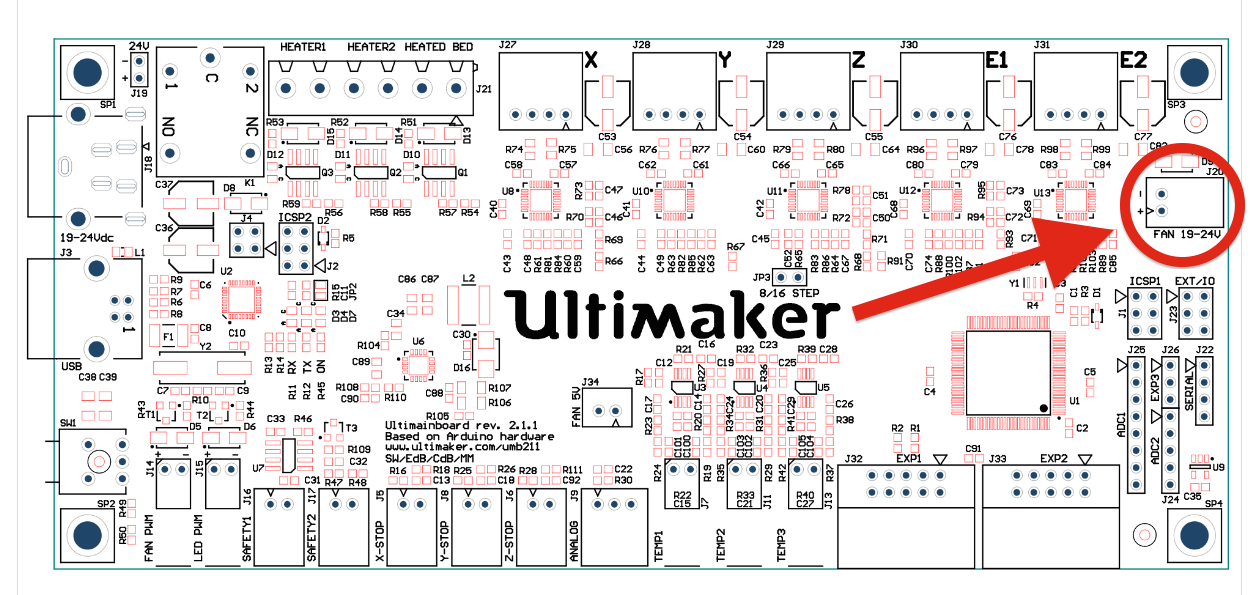

Oh. J20. No, sorry. It's always 24V. Can't change it. will that blogspot image be hosted for a few decades? Or is it likely to dissappear after a few months. In the future please use the "image gallery" icon above where you edit your post and that lets you upload an image to ultimaker so it's saved "forever".

Figured that it was constant voltage. I want to be able to turn a laser on and off via g-code. Was hoping, since it will be connected to that power supply, that it would be switchable. I can make do by detecting when the fan is on and off and then trigger based on that...unless...you have a better idea?

The image should stick but will do gallery in the future. I thought the gallery was for pictures of things you care about! It seems the forum software could just take the upload and stash it somewhere!

Why not just take the led pwn? Is Gcode control-able. And you have a laser, no need for led light ![]()

Or better...

Why not just take the led pwn? Is Gcode control-able. And you have a laser, no need for led light

I had no idea the LED was gCode controllable ("M42 S0" and "M42 S255") as that is an alternative. The laser kit that I am using is the L-Cheapo. It is a 3.5w laser so theoretically I guess I could drive it from the LED output though I am a little worried about possibly shorting it out and killing the dimmer function on the main board (from another post elsewhere here). Also wonder if a laser be driven by a PWM output?

My idea with the fans was to intercept the power supply to them and insert a low amperage current sensor connected to an Arduino. The microprocessor detects the fan being turned on and activates a solid state relay to turn on the laser. I happened to have most of the parts to do this as I do a lot of microprocessor projects.

On the firmware side...I don't want to touch the firmware so have written a Python script that pre-processes the gcode. I start with a Simplify3D profile that uses ooze control to insert retractions that I can then detect in my script. The script sees a retraction and turns off the fan (and laser). The next time it sees an extrusion it turns the fan (and laser) back on. The script also pulls out the extrusion commands as it goes along and changes layer motion from lowering the build platform to raising it.

Thanks for the idea on the LED and for any comments you might have on the above as I am now unsure of my best direction!

Will

Edited by GuestTalk to @labern. He hooked up a laser to his UM2 and I think he used the fan PWM controller. Laser's don't mind being turned on and off 10X per second.

Talk to @labern. He hooked up a laser to his UM2 and I think he used the fan PWM controller. Laser's don't mind being turned on and off 10X per second.

I will reach out to @labern. Using the fan directly would simplify things greatly. I am a little ahead of myself as I don't even have the laser yet...but...I already have a GCode pre processor written that would work directly with the FAN PWM if the laser doesn't mind it.

Here's a link to some discussion which I think includes which laser he bought. Very very inexpensive:

https://ultimaker.com/en/community/9028-hacking-um-to-cut-stuff?page=last

You don't need to go into all that effort of having Python script. Just use inkscape with the laser plugin. It generates your gcode for you. With laser on/off etc.. extruder doesn't move and you tell it what command turns laser on/off. This depends on what you control it from, led or fan PWM.

You cant power the laser off PWM. This just gives a signal to control the output power of the laser. The laser needs external power supply that has a relay switch it from the PWM signal and you read the PWM signal to adjust the laser current.

I would suggest you buy the jtechphotonics board as it does all this for you.

Thanks @GR5 and @Labern...I have ordered a board from jtechphotonics (care of Robosavvy here in the UK). Not as much fun as hacking a solution but since we are talking about a laser here spending the money seems like a good idea. Ironically, I had read the first couple pages of the post where @Labern mentioned his solution but I stopped before I got there. Not sure about Inkscape as the stuff that I want to cut will be from models in Sketchup but I am downloading a copy to look at.

Edited by GuestYou can easily convert the 3d model into a 2D format that you can import into inkscape

Saw the extra fan connector too, it says 19-24 volt. But how much current (amps/Ma) does or can it deliver? And is always on by default on any ultimaker 2 board?

Sorry for bumping up the toppic. ![]()

Saw the extra fan connector too, it says 19-24 volt. But how much current (amps/Ma) does or can it deliver? And is always on by default on any ultimaker 2 board?

Sorry for bumping up the toppic.

Anybody?

You have to be more specific. I see above there is discussion of a connector that is always on but do you want one that is pwm controllable? the always on one can handle whatever is left over after the heater and head are not used so if you aren't using the heater you have a lot of power. But if you are using one controlled by the pwm controller it will be less I think.

First figure out the connector name/number. Then look on the schematic to see what transistor/chip/mosfet is turning that on and off, then find out the part number on the schematic, then post the piece of the schematic with that part and I'll look it's specs up for you.

Schematic is here:

Click "raw" to download it as a pdf. Some pages I think are board layout maybe and some are schematic maybe.

Edited by Guest

Recommended Posts

gr5 2,210

Photo please.

Link to post

Share on other sites