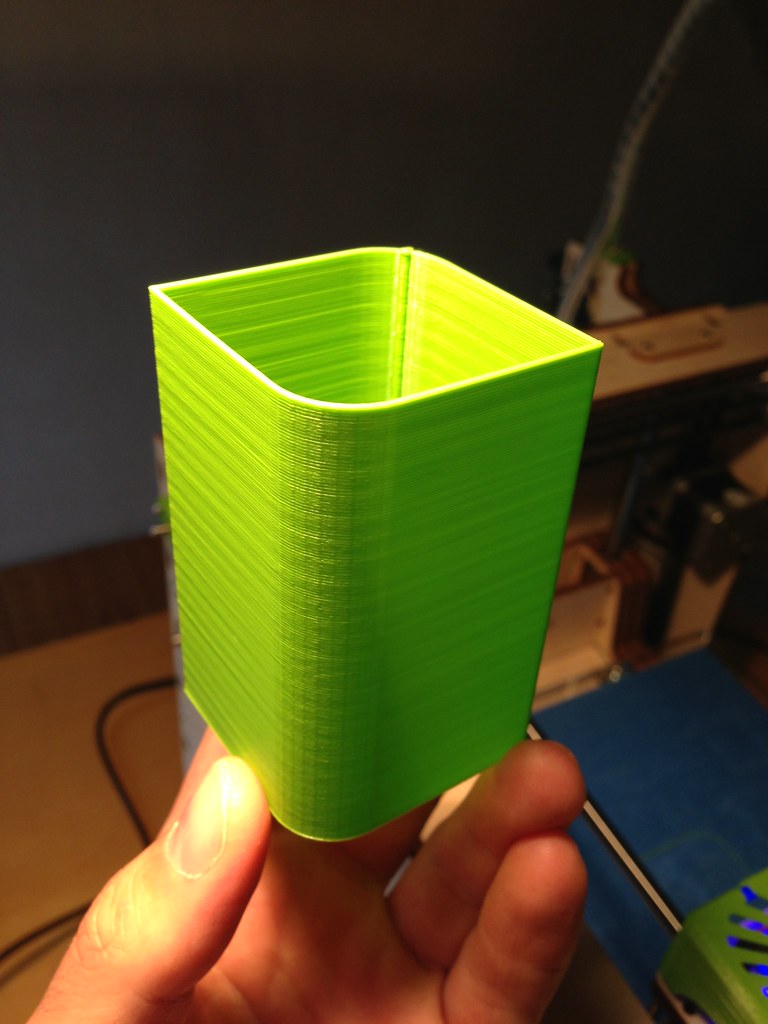

Hm, I measured the distance between the rods at the top, bottom and center. The deviation is less than one tenth milimeter...

I don't need the last 12mm - I just have a bad feeling knowing that there something wrong that I can't figure out.

Thanks for the tipps about the shims.

Recommended Posts

gr5 2,210

The grinding sound is the stepper motor missing steps. It's not serious.

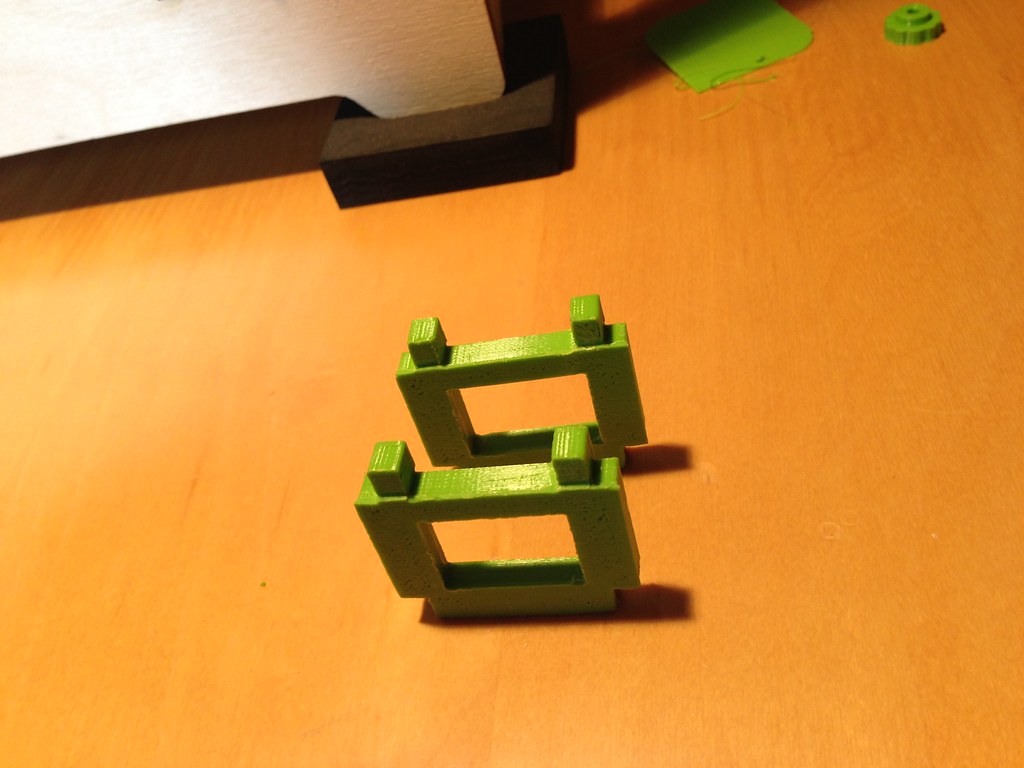

The two vertical rods probably have a different spacing at the bottom of the UM than the spacing for your bed. I fixed this by putting shims on the "left" arm of my bed. I made sure it fit before I finished assembling and did this with the z screw removed.

The design of the bed I believe is supposed to allow this spacing to change as the bed goes up and down but I didn't like that idea and tightened it up good and tight but with shims spacing the arms farther apart.

If you don't need the last 12mm then I wouldn't worry about it. I have not yet needed to use the full 200mm in Z.

Link to post

Share on other sites