Which material do you use?

Which materials do you use?

165 members have voted

-

1. What material do you use most?

-

PLA124

-

Tough PLA27

-

High temp PLA6

-

ABS26

-

CPE (+)8

-

Nylon11

-

PC6

-

PP4

-

ASA7

-

PET2

-

PETG49

-

PVDF0

-

PA3

-

Steel / metal4

-

Reinforced filament11

-

Flexible filament19

-

Other6

-

-

2. Which material has your interest, that you're currently not using?

-

PLA6

-

Tough PLA18

-

High temp PLA16

-

ABS33

-

CPE (+)6

-

Nylon30

-

PC14

-

PP10

-

ASA12

-

PET9

-

PETG35

-

PVDF3

-

PA7

-

Steel / metal29

-

Reinforced filament27

-

Flexible filament49

-

-

3. Do you use the predefined print profiles available via the marketplace?

-

Yes78

-

No87

-

Not in the list; the company I work for is developping PVC filaments to be printed on the S5 for prototyping of pipe fittings products. So far there is no way to avoid degredaded carbon buildups in the print core so I'm designing a new nozzle to fix that.

Also, not in the list. We started printing HDPE that way cheaper than PP but HPDE does not adhere to the glass build plate. Still figuring out a solution for that...

-

1

1

On 4/24/2020 at 11:25 PM, kayakbabe said:TPU and if it can be had in different densities. I want to make shoe insoles and prosthetic supports.

I'd also like to be able to make something light weight but tough enough to wear on concrete and asphalt in the summer time in Texas.Maybe with honey comb voids to help with the weight issues and to replace shoe soles for custom orthotic and prosthetics.

Hello! Yes, this is possible and we have a few different options:

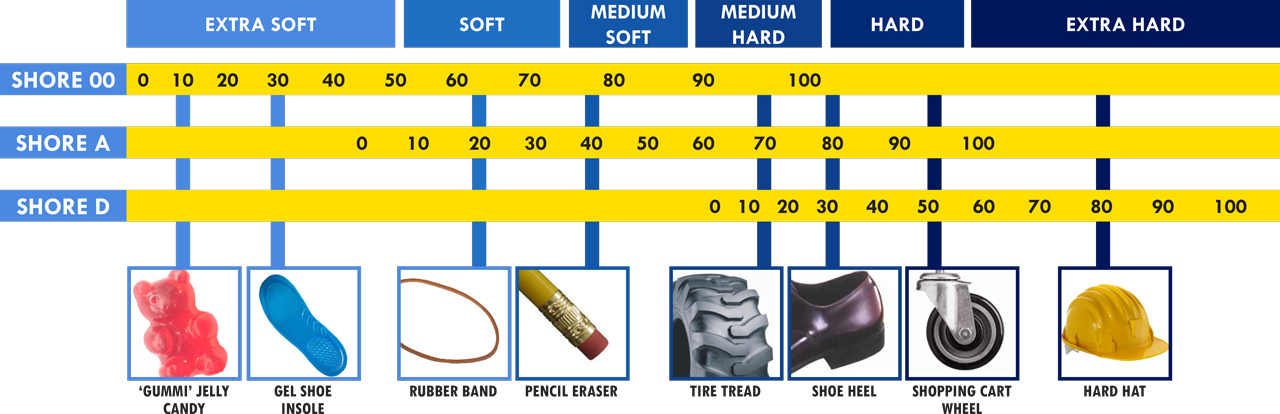

- Ultimaker TPU 95A has a Shore A hardness of 95.

- Arkema 3DXFLEX™ TPE with a Shore A hardness of 92

- Huntsman IROPRINT F 80213 has a shore A 85 hardness

- DSM Arnitel ID2045 has a shore D hardness of 34

Different Shore Hardness scales exist for measuring the hardness of different materials. There can be some overlap between the different scales. I've found this image below that illustrates what a certain value stands for:

On 4/27/2020 at 12:31 PM, DBVOLA said:We use loads of BASF Ultrafuse PET. But we use the CPE profile. The S5 Pro Bundel has a Ultrafuse PET profile. But it dos not work.

Hello, thank you for your message. Do you mean this profile?

On the profile page it says it is compatible for the Ultimaker S5 but not yet for the full Ultimaker S5 Pro Bundle. This optimisation for the material station is probably not finished yet. I'm happy to hear you found a workaround with a different profile. Would it be possible to share some pictures of the prints you've made?

Thank you!

41 minutes ago, SandervG said:

Hello, thank you for your message. Do you mean this profile?

On the profile page it says it is compatible for the Ultimaker S5 but not yet for the full Ultimaker S5 Pro Bundle. This optimisation for the material station is probably not finished yet. I'm happy to hear you found a workaround with a different profile. Would it be possible to share some pictures of the prints you've made?

Thank you!

Hi. Yes. That's the profile.

We could share some pictures. How do you want them?

1 hour ago, DBVOLA said:Hi. Yes. That's the profile.

We could share some pictures. How do you want them?

This thread would be fine. Or if you could be bothered to dedicate a few more words about your experience with the material and what application you use it for it could be an interesting read in Materials. Do you use it for a specific food safe application?

On 4/27/2020 at 5:34 PM, Framar said:Not in the list; the company I work for is developping PVC filaments to be printed on the S5 for prototyping of pipe fittings products. So far there is no way to avoid degredaded carbon buildups in the print core so I'm designing a new nozzle to fix that.

Also, not in the list. We started printing HDPE that way cheaper than PP but HPDE does not adhere to the glass build plate. Still figuring out a solution for that...

Hi @Framar, thank you for your message. Are these materials you are developing ready for use? If so I would happily introduce you to my colleague to discuss a potential adoption, so moving forward they can be in the list. Looking forward hearing from you!

Nice parts !

We are often using the UM3 for similar parts. Is support material also used with the Ultrafuse PET?

13 hours ago, stoccarda said:Nice parts !

We are often using the UM3 for similar parts. Is support material also used with the Ultrafuse PET?

Thanks.

We rarely use support. But when we do. We use PVA.

Edited by DBVOLA- 1 month later...

GregValiant 1,258

That's all well and good for you professionals. How come there isn't a "Whatever's Cheapest" category for us retired guys?

- 2 weeks later...

On 6/11/2020 at 5:22 AM, GregValiant said:That's all well and good for you professionals. How come there isn't a "Whatever's Cheapest" category for us retired guys?

Haha, is that often anything else than PLA?

-

1

1

- SandervG unpinned this topic

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

kayakbabe 12

TPU and if it can be had in different densities. I want to make shoe insoles and prosthetic supports.

I'd also like to be able to make something light weight but tough enough to wear on concrete and asphalt in the summer time in Texas.Maybe with honey comb voids to help with the weight issues and to replace shoe soles for custom orthotic and prosthetics.

Link to post

Share on other sites