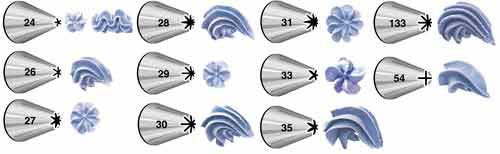

We have seen them. But I can imagine, the creative and expert group of people we are, we could even think of other nozzles / applications as well.

If not.. makes our job a whole lot easier ![]()

-

1

1

.thumb.png.f9328d507a0cd800a8ddcfd474792a50.png)

.thumb.png.4663e8ddbb0a3281ebe1e92194cfb461.png)

Recommended Posts

neotko 1,417

If you seen Anders Olsson new sexy bling bling nozzles... If not, call him, that's what Ultimaker needs =) The overhangs print so sweet....

Edited by GuestLink to post

Share on other sites