Welcome to the club Aaron!

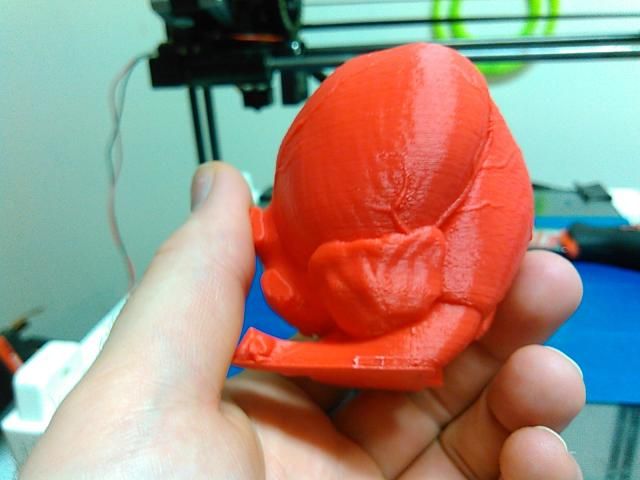

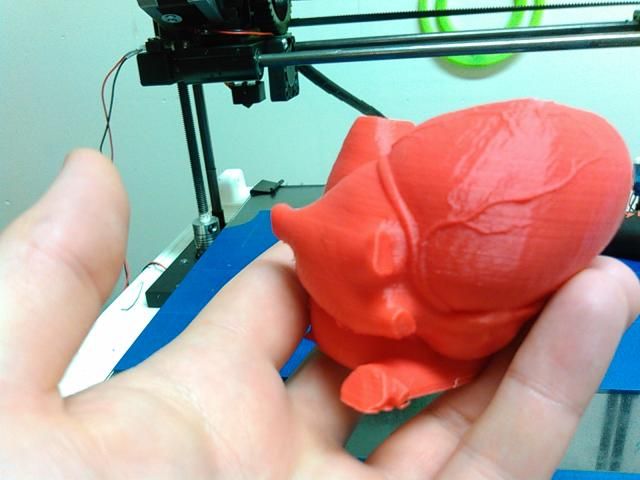

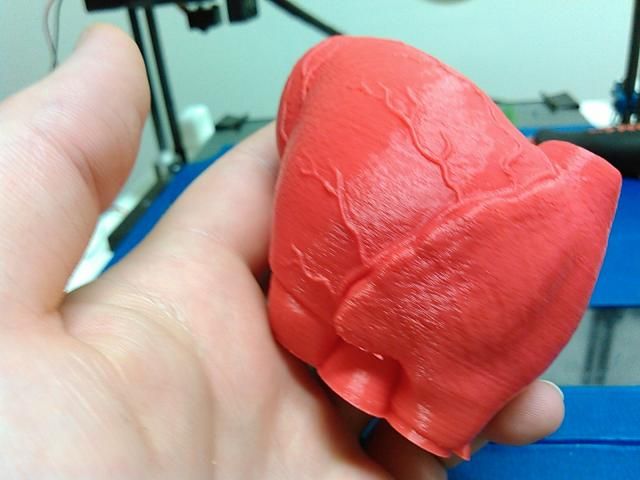

I'm a volunteer as well and I printed a test hand not too long ago, plan on printing a new one as I like how you and others have used a two colour scheme for the hand as I just printed mine out in black initially.

Love the Wolverine hand, will you be making those designs available for others to print out?

Recommended Posts

axislab 8

Hello, sorry, G.R. is my hometown. Grand Rapids Michigan. Force of habit when I typed it.

Yeah, I've printed a dozen or so hands, so I am more than happy to share tips and answer ANY questions that come with building them.

Nice to meet you.

Link to post

Share on other sites