Whether you can save that teflon coupler or not depends on if it is deformed on the inside or not.

If it is just that burnt edge, you can probably get it back in working condition with a 3.3 mm drill bit.

Under certain conditions the teflon couplers deform though, which makes them unusable (for PLA at least).

Check korneels photo of how a badly deformed coupler looks when cut in half and try to determine if yours looks the same way inside: http://umforum.ultimaker.com/index.php?/gallery/image/11465-wp-20150107-014/

Yes Anders, this is exactly how mine looks if look closely inside. So I guess it is gone.

Do you think this this enough to justify the problems I described?

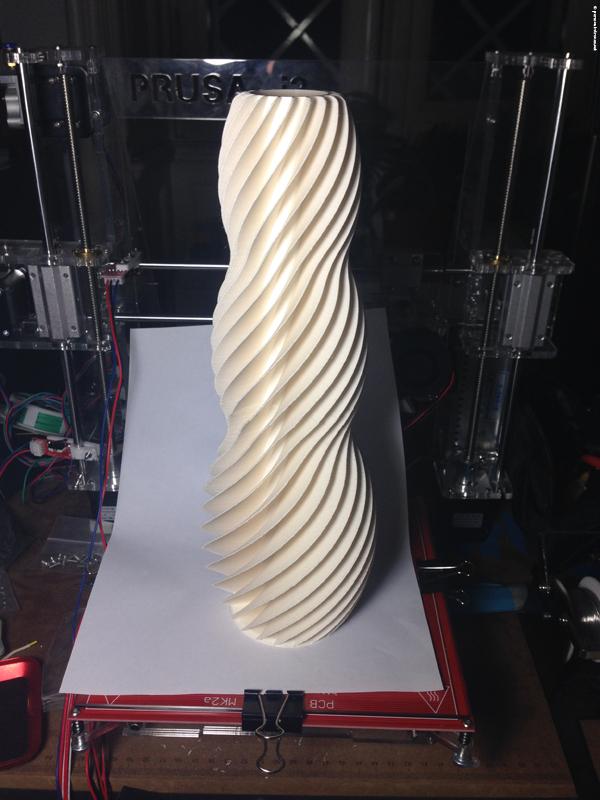

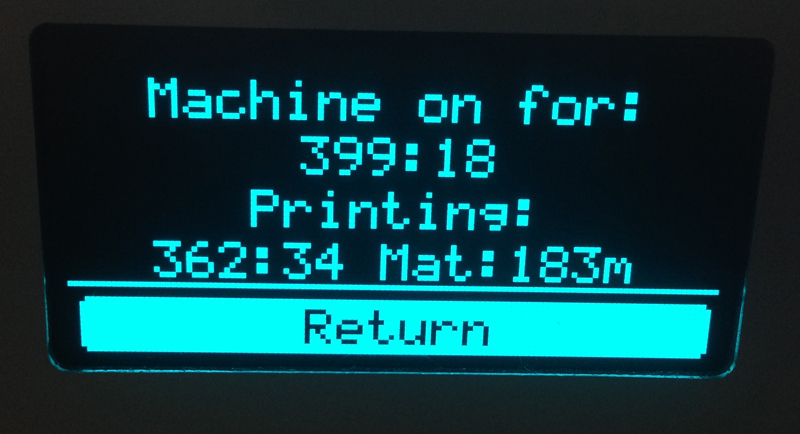

The currently ongoing print with the new teflon is still looking excellent after a few more hours, I guess this was it. I am surprised that the original teflon lasted so little, I have owned this printer for nearly exactly one month now. When the print is over I will look at the exact number of hours and post it here, for the record. Exclusively printed in PLA so far, never over 230°C.

Thanks!

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

Anders Olsson 136

Whether you can save that teflon coupler or not depends on if it is deformed on the inside or not.

If it is just that burnt edge, you can probably get it back in working condition with a 3.3 mm drill bit.

Under certain conditions the teflon couplers deform though, which makes them unusable (for PLA at least).

Check korneels photo of how a badly deformed coupler looks when cut in half and try to determine if yours looks the same way inside: http://umforum.ultimaker.com/index.php?/gallery/image/11465-wp-20150107-014/

Link to post

Share on other sites