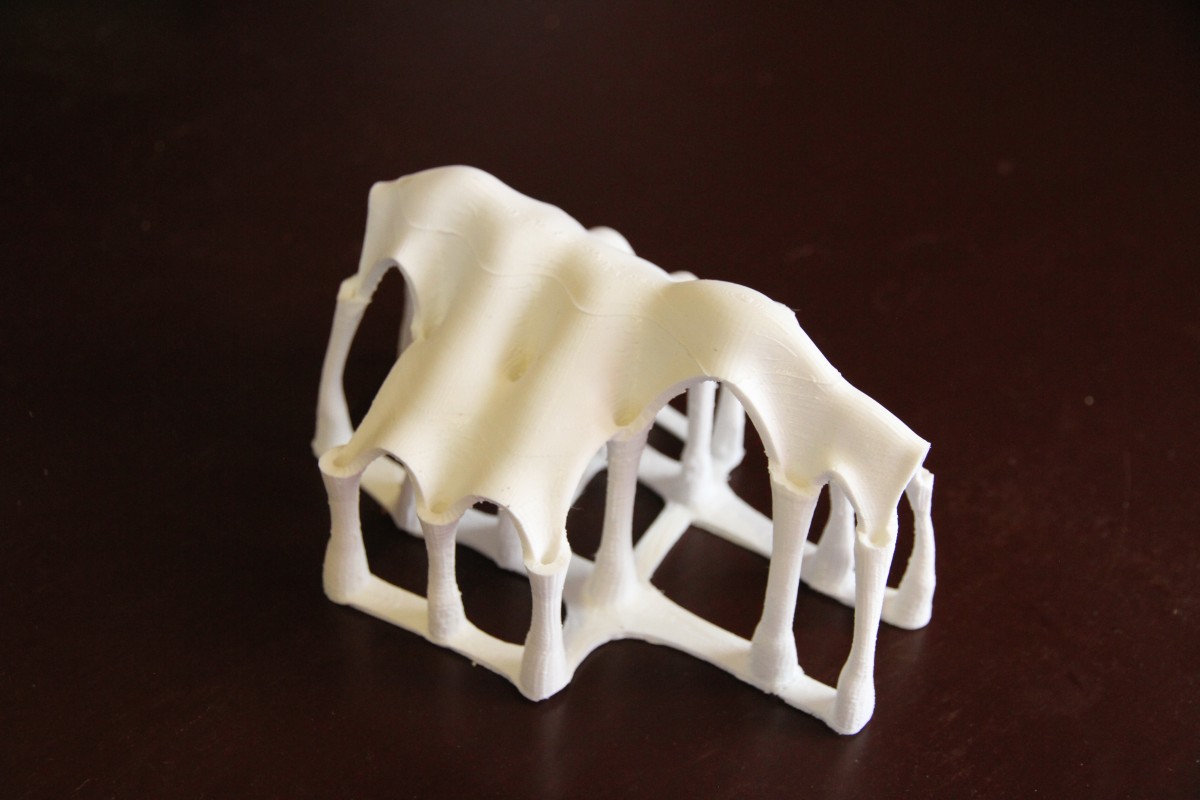

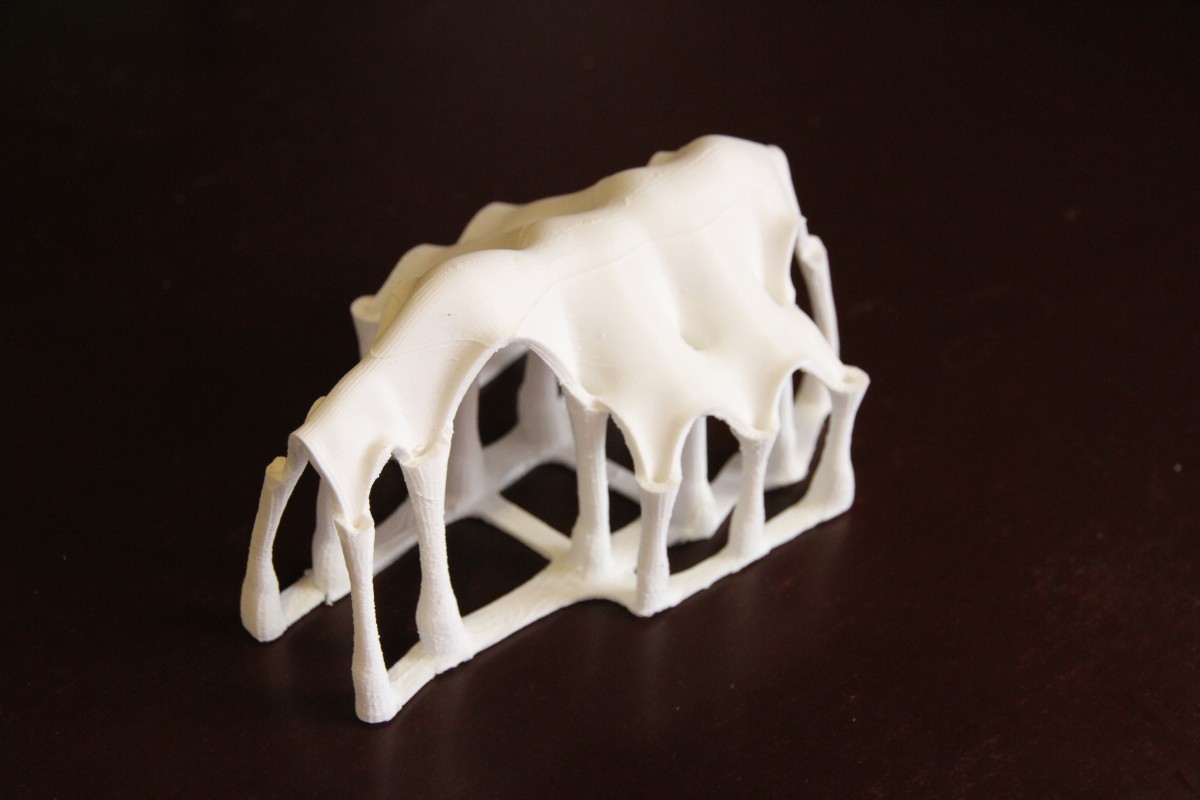

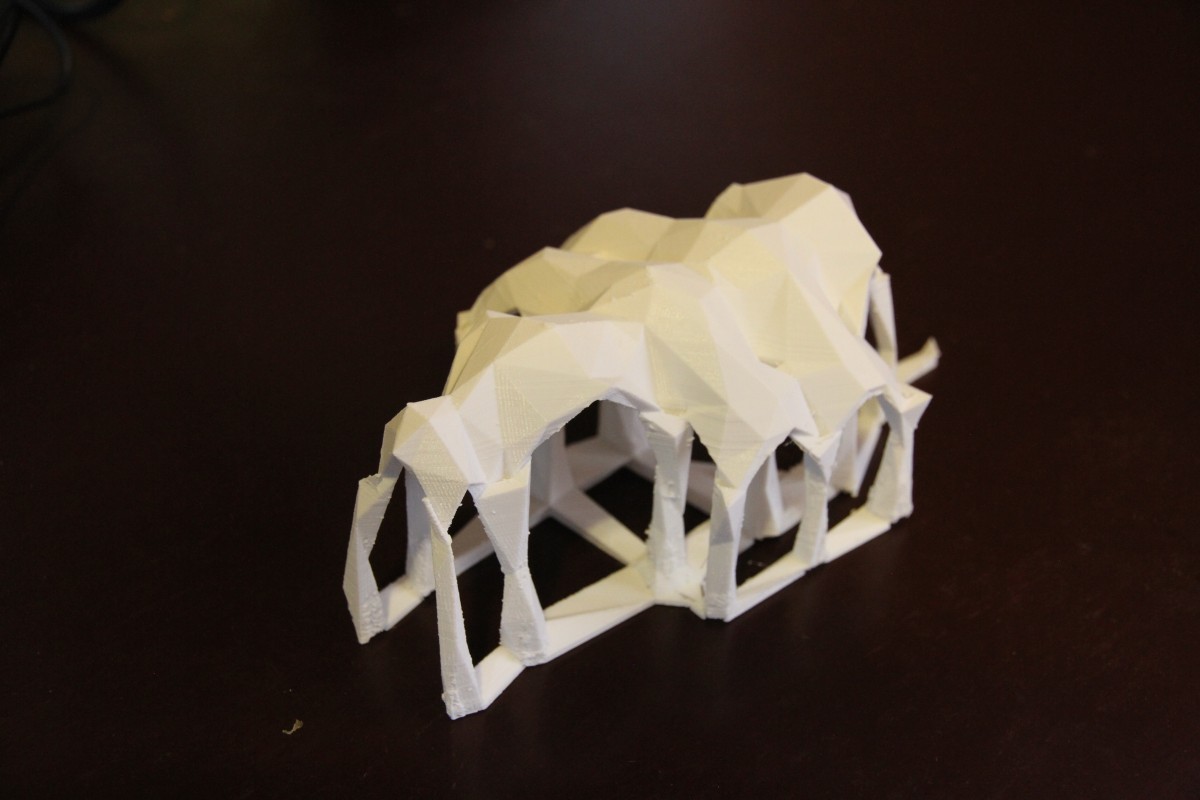

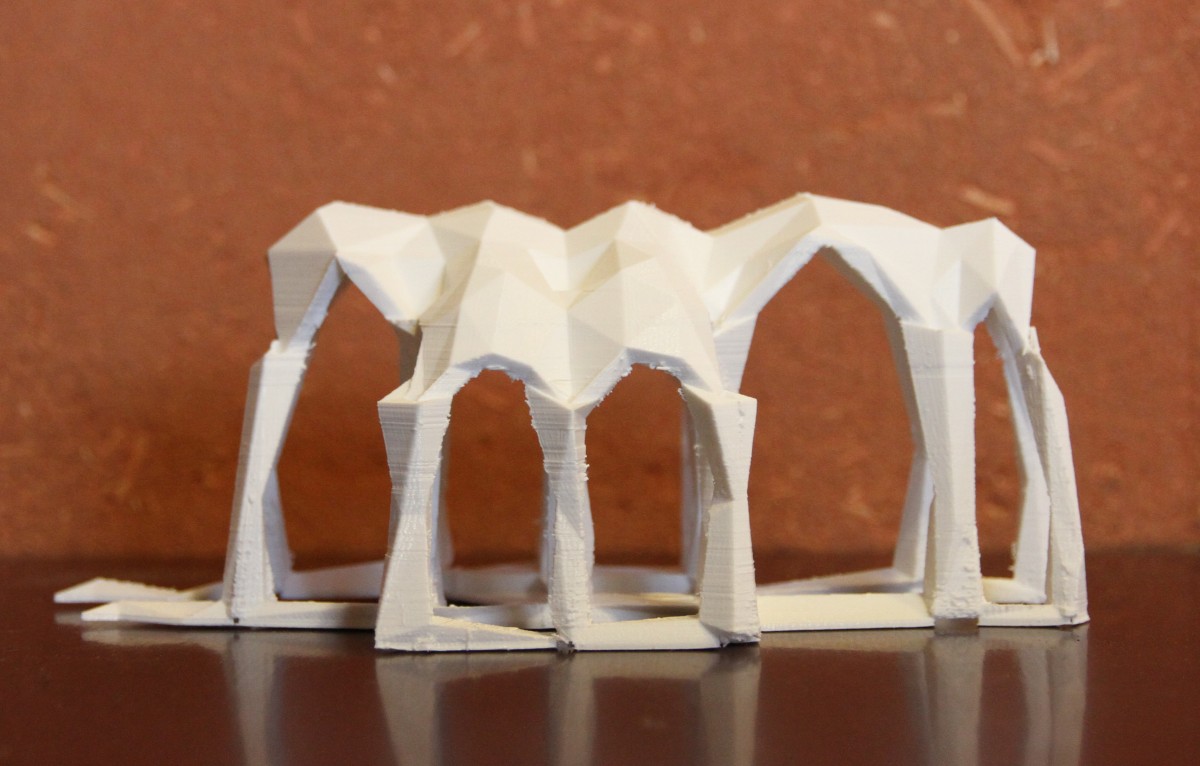

love the "desert structures" .. we get a lot of student-architects in and would love to show off your models to them (printed in laybrick / sandstone filament).

Would you care to share some of your work(files) with the community so people can see what is possible and to spark their imagination ?

demo3dmodels @ fablab013.nl

grtz,

Pete

Recommended Posts

codemaven 0

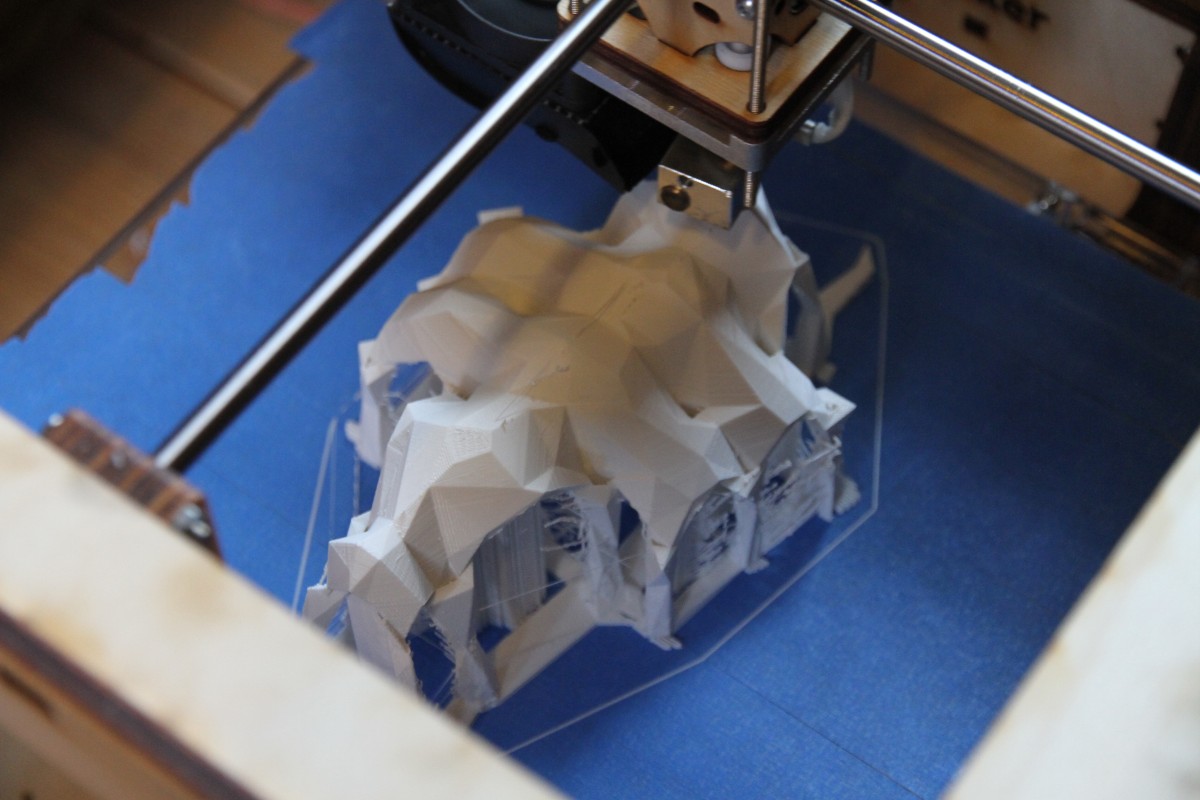

Nice work. I've just started experimenting now with the new 'LAYBRICK' filament that is basically printable stone. I've had good results with it, though not yet quite what they advertise. I'm still impressed with my results and I think it would be great stuff for architectural prints.

Cheers,

Troy.

Link to post

Share on other sites