- 0.1mm layer height seems to be what to use. I tried 0.2mm and the difference in quality is huge. 0.1mm = perfect, 0.2mm = disappointing.

Perhaps you had under-extrusion due to printing too fast/cold. It would be nice to see a photo of what you mean. .2mm at 50mm/sec is obviously twice the volume of PLA going through the print head than .1mm at 50mm/sec. So the extruder has a harder time keeping up and if the head is slowing down at corners for example you tend to get over extrusion approaching the corners and under-extrusion when it is back to full speed.

I am getting a bit of ringing, not sure how to work on that

Again, please post photo? I think I can barely see it on the left edge of the blue pillar base. Some interesting stuff about ringing here:

skip to post #8 (post numbers are shown on the right edge)

- I have got a Raspberry Pi connected, running Octoprint. The webcam feature is working, but so far I have not been able to use Octoprint to control the UM2 reliably. I am guessing Octoprint has not been setup for UM2 yet (its often used with UM1 I believe). It would be nice to send a file to the Octoprint and get it printing on the UM2 remotely, but at present I am still shuffling SD2 cards and controlling from the front panel.

Just a quick note bout OctoPrint and UM2. Due to changes in gcode for the UM2 you need to set the gcode flavor in Cura. Check out Daid's post here:

http://umforum.ultimaker.com//index.php?/topic/3223-wireless-control-ultimaker/?p=24773

Re: Retraction.

I just downloaded Cura 13.11 and sent the new firmware to the UM2.

Then I printed the MiniCalTest.stl (fresh slicing in Cura, which DID show the vertical retraction lines in preview).

The results were great - in the sample print which came with the UM2 there was LOTS of stringing, between the pillars. In the print I just did there was ZERO stringing.

So, Cura 11.13 seems to be an improvement on retraction.

Also, I had been getting some of the issues with prints aborting when it failed to read the SD card - I believe this has been fixed with the new firmware with 11.13

good to know the things comes much better for everyone, very good to see a really nice prints like abstract and Naz,that becomes more closer than we expected of UM2.

sure we get a lot of knowledge in few weeks about this machine to push it to the limits.

- 5 months later...

Hi all,

I have the same problem as seen on this video from Naz72 since a few days :

Does anyone have any tips to fix it ?

Even then I print something, I can heard a clatter noise from the material feeder (and not only during the first layer but at any time and during all the print time).

When I gently manually push the filament through the material feeder, the noise stops (even if I print minicaltest from the SD card).

Thanks for your help.

I gave up on UM in general, until today and its been more than 5 month already I cant get parts replacements & I wrote like 10's of emails & got no reply to a simple problem for the online shop when I am trying to pay for the spare parts.

theee worst service ever, printer sitting doing nothing, never never again I will buy from them, my makerbot service is excellent & its still printing as we speak even.

My Advice buy the older UM or even by pass this whole thing & go for the makerbot.

Yeah, I have the same problem...

No answers from the support and I'm already waiting for 8 filaments spools from my initial orders.

I have a Replicator 2 since a year and that's true, their support is much better than Ultimaker.

Hi LaCarpe,

I am sorry to hear you are having difficulties with your Ultimaker.

But I am sure it is nothing we can not solve.

What you are showing on the video is normal behavior.

You have just loaded new material and the feeder is pushing material forward until it extrudes.

You can extrude a couple of centimeters until the 'old' color is out of the printhead and in your case you only see Ultimaker blue coming out. The fact that it skips steps is because the motor has been tuned so instead of grinding through the filament, it skips so your filament doesn't get destroyed.

The proper workflow would be to hit Ready and the skipping stops.

Go to Print and start a print.

If your Ultimaker is calibrated correctly, which I assume it is, and you print with normal settings like 100 micron/50mm/s/210ºC you shouldn't have the skipping.

Could you let me know how this works out for you?

Thank you

I gave up on UM in general, until today and its been more than 5 month already I cant get parts replacements & I wrote like 10's of emails & got no reply to a simple problem for the online shop when I am trying to pay for the spare parts.

theee worst service ever, printer sitting doing nothing, never never again I will buy from them, my makerbot service is excellent & its still printing as we speak even.

My Advice buy the older UM or even by pass this whole thing & go for the makerbot.

Hi Naz,

I am sorry to hear about your experience with Ultimaker.

I remember we spoke when you just got your Ultimaker and we replaced it because it had some difficulties.

After the replacement I do not remember speaking to you again, have we?

If you are still experiencing difficulties please get in touch with me or the technical support team so we can offer you our assistance and turn your experience into a more positive one.

We do not ever want to leave our users in the dark, and if you have an Ultimaker 2 sitting there doing nothing I think we should work together to get it back to printing.

I am looking forward hearing from you!

Dear Sander,

As you can show in my previous message, this didn't happen only during the loading step but also during normal print.

I also tried to print with "standards" settings and there is always this slipping. This results on a not fully extrusion and bad quality printings (especially at 210°C, I have to set up at minimum 220°C with PLA or it didn't extrude properly).

Please, note that during the early days, this UM2 dind't have slip issues. So, this proves this is a new issue.

For me there is a mecanical or electrical failures. Especially in regards of the other problems that I have this machine sice I received it (as I said by mail and still waiting since for a response 2 weeks).

Anyway, I'm truely disapointed by Ultimaker machines and customer care. Same feeling than Naz, I've spent 2000 € for an "ornemental" machine which never works propelry while my other printers still works well and running everyday since more than a year.

The worst is this awful feeling about that Ultimaker don't care about customers complains and didn't do is best to improve the situation by fixe hardware issues or take serisously the users complains.

Note that I have ask for a repair or a replacement to your sales departement (this only because I haven't obtain the information to how getting back this machine to Ultimaker and obtain a refund when I just received it...)

Best,

Lacarpe, the skipping backwards of the extruder is designed that way on purpose so you don't grind the filament. It only happens when there is very high force on the filament - it skips backwards at around 5kg force. Other people have had the problem you describe where the skipping got worse after using the printer for a while.

Unfortunately this is not trivial to debug. There is a test here to see exactly how bad the problem is (must be done at 230C to compare properly to expected results):

http://umforum.ultimaker.com/index.php?/topic/4586-can-your-um2-printer-achieve-10mm3s-test-it-here/

A new UM2 should be able to get up to 7 cubic mm/sec (or faster) but printers that can print up to 3mm aren't too bad as I don't think I ever go over 3 cubic mm/sec anyway.

I recommend you do that test. If your printer is getting 7 you might just need to slow down your prints a little or raise the temperature. If the test indeed shows a problem then unfortunately there are about 10 solutions to try including:

1) Getting a new stronger teflon isolator

2) Putting filament spool on floor

3) Cleaning abs out of the nozzle (the black feeder is made from ABS and some of it may now be in your nozzle)

4) Increase current to feeder (increasing from standard 1.35A to 1.5A makes a huge difference for some people)

And many more

For some people #1 was all they needed to do. For others one of #2 through #4 was all they needed to do. But the first step is to prove that you have a problem with the link above. Prove that you aren't simply printing too fast or too cold.

The original posts here were last November. Many of us have learned a lot since then. I think if you start over and do the above test there is a lot that the forum can do to help you or that Ultimaker can do. Ultimaker has also done some serious research and has some interesting solutions for the small amount of people with this issue.

Hi Laurent,

Thank you for your reply.

Looking in our communication system I see we have been in touch before in regard of your fan and you have now

been in touch with my colleague. The response time has always been within 1-2 days with an exception of the last reply. I understand it can be frustrating to have a stubborn technical problem, but we are here available to help you and get back to trouble-free printing, just as the community.

GR5 has some good tips which I recommend you try.

It is no problem for us to send you a new teflon isolator, but by my understanding Marrit will also offer you the service of picking up your Ultimaker and have it repaired by us.

If you have any further questions on how to proceed please feel free to ask.

Thank you for your time,

Thanks for your answer gr5.

I will try this test as soon as possible

Dear Sander,

I can understand that issues can appaears on old printers. But I have problems with my UM2 since I received it.

Regarding to this, I wouldn't have to disassemble or change any part of this printer or change any current settings.

Several technical issues, missing stuff on my order (since 6 weeks), many difficulties for having contact with support (yeah, 1 or 2 weeks once I spent 8 days by call support center and sent many e-mails. And then, no answers for 10 days when I give some feed-pack about the new fan which didn't work too).

I'm sure you do your best but trust me, my Ultimaker experience really looks like a nightmare.

I was asking for a refunding and give back this printer one week after I received it. Seems this request wasn't favored. Good things, Marritt offered me a repair. i just hope that DHL will contact me soon for the pick.

Best,

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

naz72 0

Thank you illuminarti,

I am really happy things are starting to work better already & appreciate all your feedback & help & everyone else, I need to start playing around with smaller prints to test which best settings works for me, like I did with the older UM.

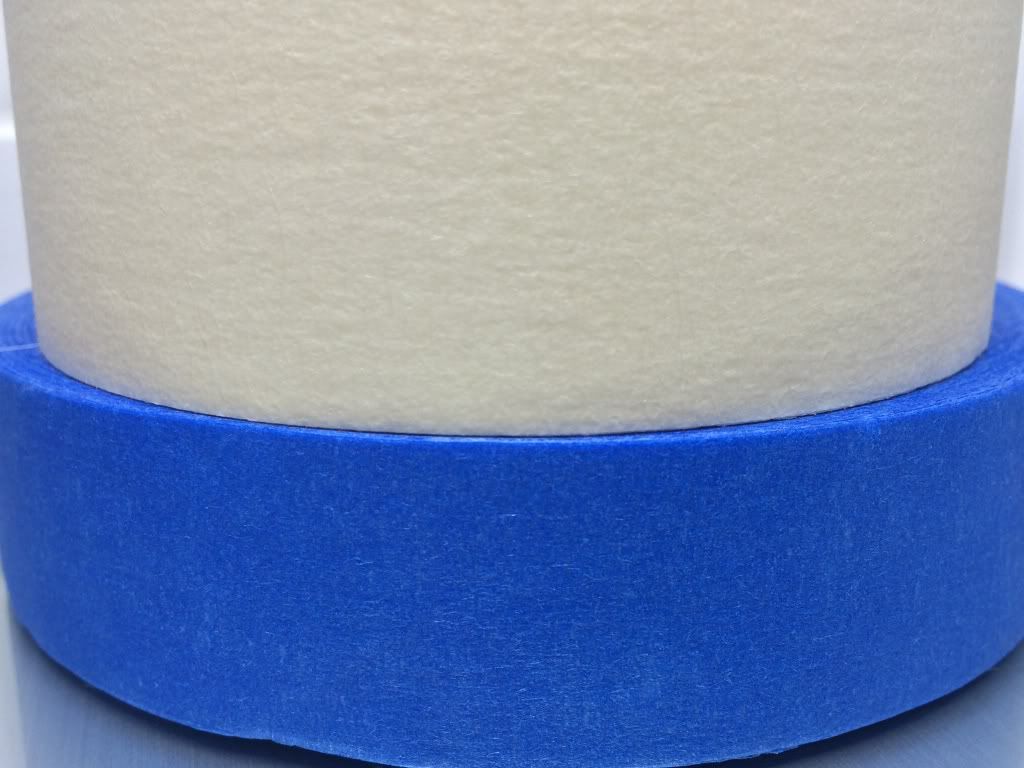

here is a picture of when I was testing the settings for my older UM.

here is a Tip for all those using the Blue tape, if you see the last pic its using a White tape, im not sure which exactly but it works a LOT better than the blue tape, it sticks as good if not better than the blue tape but the best thing is its re usable & you don't have to keep changing tape as it doesn't tear when removing the print.

If you guys ever fid it, please try it & I promise you wont go back to the older Blue tape. you can see from the pic how many times I printed on the same tape.

Link to post

Share on other sites