I think there are a couple of cooling-related issues, and they kinda work against one another.

In order to print faster, and cleaner, you want to cool the freshly extruded filament as quickly as possible below its glass temperature. This should help with bridging and overhangs, and also prevent the sides of prints sagging under gravity when printed fast such that heat is getting added faster than it is lost.

On the other hand, in order to prevent warping, I think you want to minimize overall cooling. This plays into the 'side away from the fan' discussion. I find that if I have large flat things are likely to warp up off the bed, this is most likely to happen on the right side of my print (my fan is on the left of the head). Contrary to the received wisdom about the 'side away from the fan' being cooled less, and so printing worse - I think it's the opposite. That side of the print gets more overall cooling, but at a slower rate. Because wherever the print head is, if the fan is on, there's some amount of airflow over that side of the print. The left side of the print gets cooled less overall, because much of the time it is below and behind the fan opening, and only gets blown on when the head is on that side of the printer.

This interpretation would seem to be supported by the fact that when you turn off the fan totally, the warping gets better, or often goes away, rather than getting worse.

However, you should also bear in mind that, at the moment the filament is laid down, it is always a constant distance from the fan opening. The amount of time it spends in the most intense cooling air stream will depend on the direction the head is moving. For a fan-on-the-left set up like mine, with the nozzle towards the front of the head (and hence fan opening), extrusions spend least time in the air stream when printing from left to right (as the extrusion quickly passes under the fan), or from front to back (as the extrusion passes out of the airstream quickly as the head moves towards the back of the printer).

Conversely, when printing a line from back to front, the fresh extrusion gets probably the most immediate cooling, as the entire length of the fan opening passes close by it. Segments printed right to left probably also get cooled quite well, since although the fan is moving away from the extrusion, it remains in line with the air stream and so gets some smaller amount of cooling for longer.

I suspect this may be the root of the 'side away from the fan' mythology... if printing loops in an anti-clockwise direction (which used to be fairly typical - SteamEngine mixes it up a bit at the moment) the left side of the print 'nearest the fan' gets the most intense cooling, while the opposite side gets much less. Hence improving short-term performance on bridges and overhangs. But in the long term, that side tends to cool faster, and so warp more.

So overall... I think the best way to test cooling effects is to look specifically at what difference it makes to minimum layer times, bridges and overhangs on perimeters. It may well be that actually, cooling is best used targeted to just loops and bridges (including the transition from sparse to solid infill). And then turned off for (non-bridging) infill, in order to slow down the overall cooling and help reduce warping forces. Kisslicer for one allows fan speeds to be set independently for these.

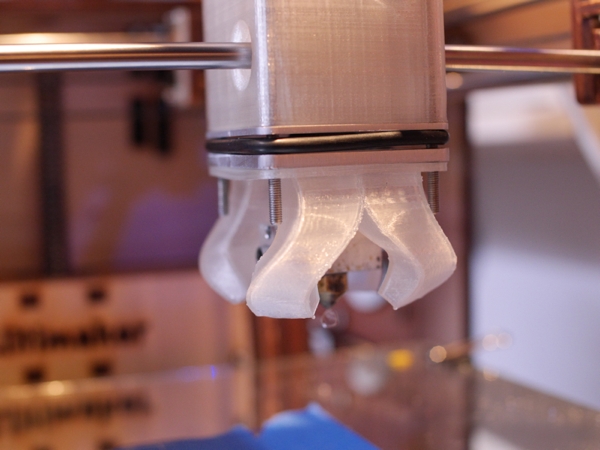

On the issue of blowing on the tip... it really depends what you are trying to achieve. I've certainly helped troubleshoot at least one user who had a dysfunctional fan shroud that was cooling the nozzle tip quite heavily to the point where his prints were coming out really badly, and having lots of jams. At the end of the day, all it's doing is lowering the extrusion temperature, so that while you think you're printing with 220º plastic, in actual fact you're printing with 180º plastic. So it's going to flow less well, and take higher pressure, and so under-extrude more. If what you want is cooler plastic, probably best to just lower the overall temperature - because with a cooled tip, while extrusion is harder, and pressures higher, you do still have a reservoir of very molten plastic at even-higher-than-usual pressures that might be looking for ways to squeeze back up into cooler parts of the head and cause problems.

Recommended Posts

Top Posters In This Topic

30

25

14

8

Popular Days

Sep 8

9

Sep 7

8

Sep 20

8

Sep 16

6

Top Posters In This Topic

madoverlord 30 posts

foehnsturm 25 posts

owen 14 posts

nick-foley 8 posts

Popular Days

Sep 8 2013

9 posts

Sep 7 2013

8 posts

Sep 20 2013

8 posts

Sep 16 2013

6 posts

gr5 2,210

I've done some experiments with cooling but I still don't feel like I fully understand it.

I'm pretty sure the fan should only cool the part. Daid I think once mentioned that if the fan cools the tip of the nozzle it can cause problems. I am a little skeptical - I think having the fan cool the nozzle might help reduce leakage/stringing. I don't know.

I've come across certain prints that are very sensitive to cooling. Most often they are shapes that are clearly defined (like a cube) such that if they are deformed it is obvious. When one prints a Yoda for example, if it is deformed, no one can tell. If his ears are at the wrong angle or his cheek is 1mm in the wrong place even an expert can't tell. But if a square has one rounded corner or is rectangular it is more obvious.

I found that when I print "too fast" sometimes squares posts are clearly deformed. Especially if the post is at an angle with some overhang.

Another great example is the UM Robot. When you get to the top, his two antennae print amazingly slowly. If you disable the minimum layer time feature they look like crap.

Also long ago I experimented with trying to figure out how long it takes PLA to "freeze" just by spinning the extruder, watching string come out, and playing with the string until it seems to harden. It's about 3 seconds with no fan. But it's really hard to measure exactly. It happens very fast and it's subtle. Also this isn't a good test because it's in free air so it cools fast.

So a few weeks ago I did an experiment. I want to go back to it at some point. Anyway I came up with a very tall and skinny box shape tilted at 45 degrees. This turned out to be a great test piece for cooling.

I basically concluded that with the fan completely off you need a minimum layer time a little higher than with the fan on but that you don't really need the fan. I got something like 5 seconds with fan, 10 seconds without. Something like that - I posted my notes somewhere else on this forum. I want to repeat the test with my heated bed turned on.

Anyway - that's just one particular shape/test. There have been quite a few people who have bad tops of their parts if the fan is broken. One person knew his fan was broken and had ordered a new one, the other had the wires backwards and it was sucking air. Lets see if I can find both examples:

Damn. The search features on this forum suck. For example if I search for "fan" there are zero results. Anyway there was a post within the last week from this guy printing dozens of frogs. After his fan broke they tops looked crappy. A few months ago another guy had his fan sucking. His parts looked exactly like the base in this print where the are holes in the top:

http://umforum.ultimaker.com/index.php?/topic/2701-strange-effects-on-falt-surface/?p=19426

Illimuniarti did some experiments and came up with a conclusion that related to both the fan and the infill pattern (the top has to bridge the infill). It's not clear to me in this example (covering up the top of something by bridging the infill with strands of PLA) if the fan needs to blow on the nozzle, the filament, or the part but maybe Illuminarti has something to offer.

By the way tons (tons!) of people claim the "fan side" looks different. But the fan blows more from *above* than from the side. When the part is *done* printing or almost done it looks like the fan is blowing on one side but as it prints -- the current layer is what is important, not some layer that was printed 10 minutes earlier. So I'm very skeptical about this whole "fan side" thing. But there is something to this claim - I just don't know what it could be. Probably it has more to do with uneven shrinkage.

Link to post

Share on other sites