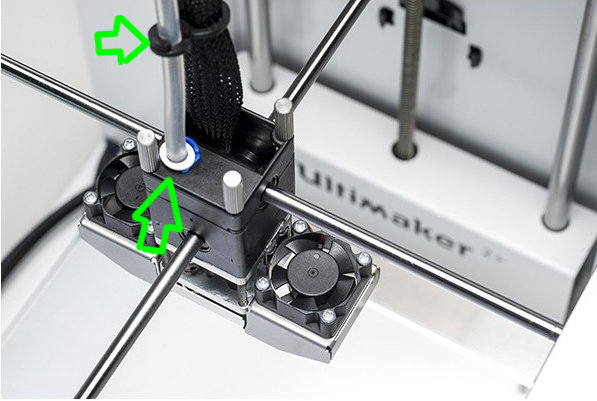

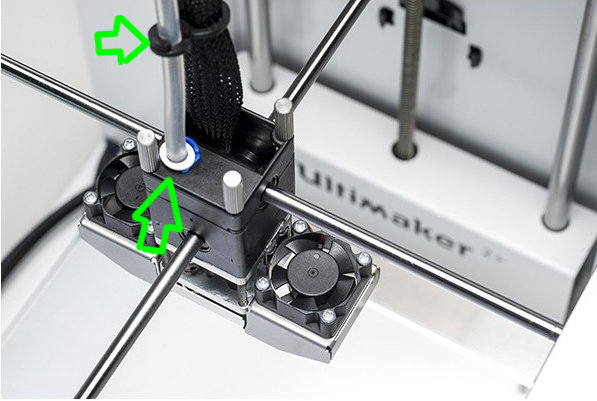

Depending on your situation where the filament is broken, remove the Bowden from the print head only, or on both sides. Then heat up the nozzle to 200° and pull out the filament. That's it, no need to do more.

I guess the filament broke just because it sits too long in the tube and got brittle. This is quite normal for PLA.

Recommended Posts

NBull 14

I would disconnect the bowden at the print head and some of the wire clips. so you can pull the bowden off the filament piece. then manually heat the printhead til the filament can be pulled out. Assuming theres still a bit of filament left over the print head when the bowden is removed. so you have something to pull on.

(Disclaimer, its a long time since i have worked with the u2, so there might be a better way to do it)

Edited by NBullLink to post

Share on other sites