I recommend this method: http://umforum.ultimaker.com/index.php?/topic/5951-calibration-utility-leveling-ringsgcode/

It's a gcode for printing large concentric circles very slowly. You can easily adjust the calibration screws while printing. It gives much, much better results than using a sheet of paper.

Recommended Posts

DidierKlein 729

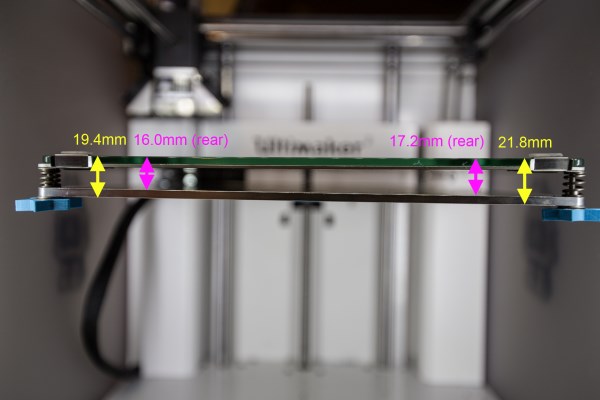

Not sure about this but maybe there is something that makes the plate higher on the upper right and a bit lower on the upper left.

Maybe check the screws (not sure what screws).

And take a look at the manual you can download here to help:

https://github.com/Ultimaker/Ultimaker2/blob/master/um2%20assembly%20manual%20V1.1%20_english.pdf

And also make sure you're on the latest firmware there was a bug in leveling with previous firmware (14.07 solves it)

Link to post

Share on other sites