Anders, i'll dont think Nickel would be that much better for the kind of printing you do at work tough, you would probably be better off looking at synthetic diamond coating or similar at the rate you are destroying nozzles ![]()

Anders, i'll dont think Nickel would be that much better for the kind of printing you do at work tough, you would probably be better off looking at synthetic diamond coating or similar at the rate you are destroying nozzles ![]()

We have an MakerBot Replicator 2X that hardly gets used anymore, Maybe I'll convert that to use a 3mm E3D nozzle. I'd like to keep the ultimakers as stock as possible.

I found a place nearby that is willing to coat the stock nozzles with a couple different nickel coatings for free (they just want feedback on how the different coatings perform). Has anyone been using ColorFabb XT-CF20 that can provide some feedback on the uncoated nozzle wear?

Well, nobody can beat free, but FYI nickel plating at home is trivially easy. Here's a YouTube video on the subject :-

But, ignore his (impossible to find) Nickel plating solution, and scroll down the comments for the recipe given by MrSwanley (that would be me... :-).

I used this trick to nickel plate some copper coins. The trick is to get the brass or copper spotless clean, i.e. scrub with soapy water to get rid of grease, then soak in salt and vinegar to remove oxide layer. Pure nickel welding electrodes and nickel sulfate electrolyte can be found on eBay.

I had thought about trying it myself (found some kits online to do it) but the industrial electroless nickel plating that they offer is actually a composite coating, adding PTFE, Boron Nitride, Carbide, and Diamond to give better hardness and low friction. Plus it means I don't have to mess around with nasty chemicals or risk ruining a $50 nozzle :wink:

Plating diamond? Pull the other one! ![]() It isn't even a conductor is it? Vapor deposition maybe, but not plating!

It isn't even a conductor is it? Vapor deposition maybe, but not plating!

Btw, Nickel Sulfate isn't really that nasty. It's just a salt. I wouldn't want to drink the solution, but then I wouldn't want to drink seawater either!

I'm not exactly sure how they do the composite coating. Here is their spec sheet: http://www.twincityplating.com/resources/TCP_fctsht_XT.pdf

"Electroless Nickel (EN) composites have been used for many different purposes for a number of years. Given EN’s amorphous structure, polymers and other non-conducting materials can be co-deposited providing capabilities above and beyond traditional EN. Teflon, Carbide, Diamond, Boron-Nitride – can all be used to improve the characteristics of the coating – Hardness, Lubricity, Corrosion Resistance, Abrasion Resistance, etc"

The plated nozzles should arrive later today. I've been running the XT-CF20 on one of our UM2s to get a good baseline on what the true wear will be on an uncoated nozzle. You can already see some wear on the tip of the nozzle. The leading edges of the nozzle now have a pretty big radius on them.

I have to say I LOVE the XT-CF20 filament. Its super rigid and has almost no warping (even better than PLA). Overhangs and bridges are great as well.

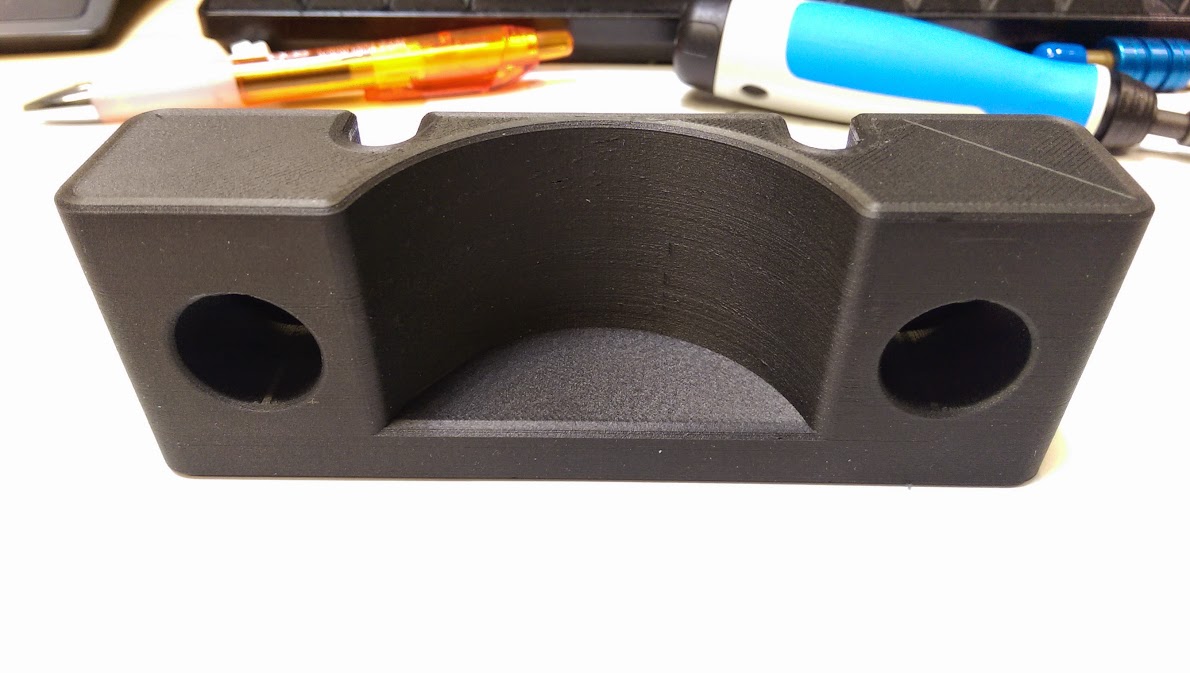

Small fixture jaw at .05mm (no supports, raft or brim)

Large fixture jaw at .12mm (no supports, raft or brim)

Gear test at .12mm (no supports, raft or brim)

Once I've run through a full roll I will switch to one of the coated nozzles.

The plated nozzles should arrive later today. I've been running the XT-CF20 on one of our UM2s to get a good baseline on what the true wear will be on an uncoated nozzle. You can already see some wear on the tip of the nozzle. The leading edges of the nozzle now have a pretty big radius on them.

How much did you print with that worn nozzle?

The nozzle has probably seen 500 hours printing PLA and has gone through about half a roll of XT-CF20. The nozzle ID still looks pretty good but the tip is seeing a lot of wear.

Have you measured how much has been worn away?

I was starting to get bad prints so I decided to swap out the nozzle early. The ID is measuring 0.05mm oversize but the really supprising thing is how far the nozzle tip has degraded. The overall length of the nozzle shrunk by 0.5mm. The tip diameter is hard to measure but its around 2mm now where it should be 1mm.

They really aren't kidding when they say the carbon filament is abrasive.

@MendellS: So you often had to relevel the bed?

@MendellS: So you often had to relevel the bed?

Yes, several times actually. It was getting to be a bit annoying, I could get through 2-3 prints then have to re-level the bed. The inconsistency caused by using the glue stick on the bed didn't help either.

I went to the London 3D Hub meeting tonight, and got some ColorFabb samples inc. CopperFill, BambooFill and XT-CF, one of the guys giving the talk said he got through 3 nozzles for a roll of XT-CF...So my sample will be waiting untill ive upgraded to a new E3D nozzel system. Although one person did mention about getting the nozzel diamond coated! May need to look at that, the steel nozzels have a few quirks.

I have been in discussions about diamond coating nozzles lately and I might actually get a sample the coming days since I happen to know a guy with a "diamond machine" :smile:

However, diamond is not completely straight forward to work with.

There might be other materials which are easier to work with and might give sufficient lifetime of the nozzle.

We have several ideas that needs testing, just need to find time... :smile:

So, these somewhat surprising results make me wonder. If the nozzle wear is so obvious and huge, what is the carbon filament doing to the rest of the system? Especially the hot end isolator coupler and the isolator tube seem vulnerable, but the bowden cable and bolt might be at risk too.

I went to the London 3D Hub meeting tonight, and got some ColorFabb samples inc. CopperFill, BambooFill and XT-CF, one of the guys giving the talk said he got through 3 nozzles for a roll of XT-CF...So my sample will be waiting untill ive upgraded to a new E3D nozzel system. Although one person did mention about getting the nozzel diamond coated! May need to look at that, the steel nozzels have a few quirks.

I have been in discussions about diamond coating nozzles lately and I might actually get a sample the coming days since I happen to know a guy with a "diamond machine" :smile:

However, diamond is not completely straight forward to work with.

There might be other materials which are easier to work with and might give sufficient lifetime of the nozzle.

We have several ideas that needs testing, just need to find time... :smile:

I've asked around and most "diamond" coatings, like those you would find on cutting tools, can't be applied to brass or other alloy substrates. If you had a steel nozzle I imagine it might be possible?

So, these somewhat surprising results make me wonder. If the nozzle wear is so obvious and huge, what is the carbon filament doing to the rest of the system? Especially the hot end isolator coupler and the isolator tube seem vulnerable, but the bowden cable and bolt might be at risk too.

Well I'm not worried about the isolator...

I work at a machine shop so we just made a bunch of spares. We seem to be replacing them every 2 months or so anyways.

I've checked out the bowden tube and drive mechanism and it all looks fine. Brass is really soft so its not surprising that the carbon filament is wearing it down so fast.

I've printed two rolls of xt-cf20 with Olsson Block and a 0.8 E3d stainless steel nozzle. The nozzle seems to be ok. But XT-cf20 is sticky then I've some difficulties with the overhangs, when the filament doesn't adhere on the print there's a heap of material on the nozzle which is leaved later on my print.

It's not as easy as simple XT to print.

Have you an other practice?

Wow this is a super informative thread.

btw, @MendellS, how did you make so many ptfe isolator parts? Did you make a mold or something?

It would be handy to be able to buy extra ones since they do start wearing down after a lot of printing.

I've printed two rolls of xt-cf20 with Olsson Block and a 0.8 E3d stainless steel nozzle. The nozzle seems to be ok. But XT-cf20 is sticky then I've some difficulties with the overhangs, when the filament doesn't adhere on the print there's a heap of material on the nozzle which is leaved later on my print.

It's not as easy as simple XT to print.

Have you an other practice?

I am currently experimenting with a modified nozzle with smaller flat area. It appears to improve the quality of overhangs.

You can have a look at the comparison I made some time ago, the trend seems to go towards smaller flat area (Makerbot MK8):

I am not sure if the same thing is valid for stainless steel, I have only been using a modified 0.4 mm brass nozzle so far.

Next thing in my list is to test a modified 0.8 mm nozzle, I just need to finish ~50 hours of urgent print jobs first :smile:

Anyway, if you have access to a lathe, you try decreasing the flat area of the 0.8 mm nozzle (from 2 mm) to about 1.4 mm.

Thanks Anders for your answer and your great development .I haven't access to a lathe, then I will wait that you design a new nozzle.

Please Anders , improve this nozzle....please

I just watched the E3D talk from MWRRF (MidWest RepRap Festival), and they show some pictures of the wear that XT-CF20 puts on the nozzle

This picture is supposedly of two E3D Nozzles where the one on the left has printed about 10kg of PLA, and the one on the right has printed 250 grams of XT-CF20, quite some wear visible, and deforming of the final channel in the nozzle.

Wow this is a super informative thread.

btw, @MendellS, how did you make so many ptfe isolator parts? Did you make a mold or something?

It would be handy to be able to buy extra ones since they do start wearing down after a lot of printing.

I work at a machine shop so we just ordered a bar of glass filled PTFE and turned them up on a CNC lathe.

I just watched the E3D talk from MWRRF (MidWest RepRap Festival), and they show some pictures of the wear that XT-CF20 puts on the nozzle

This picture is supposedly of two E3D Nozzles where the one on the left has printed about 10kg of PLA, and the one on the right has printed 250 grams of XT-CF20, quite some wear visible, and deforming of the final channel in the nozzle.

Great link, thanks for sharing!

Unfortunately after round 20 hours of printing XT-CF20 the nickel plating is already gone off the tip of the nozzle. I will switch nozzles here soon but I am not confident that they will make much of a difference.

Next step is to make a new nozzle out of stainless but that may take a while as it will require some custom tooling.

Recommended Posts

Top Posters In This Topic

10

8

8

5

Popular Days

Jul 30

15

Mar 10

5

Mar 25

4

Mar 9

3

Top Posters In This Topic

mendells 10 posts

Anders Olsson 8 posts

danilius 8 posts

neotko 5 posts

Popular Days

Jul 30 2015

15 posts

Mar 10 2015

5 posts

Mar 25 2015

4 posts

Mar 9 2015

3 posts

Posted Images

Anders Olsson 136

I am currently printing XT-CF20 with a E3D brass nozzle, so I might be able to give you a report on the wear soon :smile:

If you think stainless nozzles is good enough, you could consider upgrading the heater block to get exchangeable nozzles: http://umforum.ultimaker.com/index.php?/topic/7689-custom-heater-block-to-fit-e3d-nozzle-on-ultimaker-2/

And buy stainless nozzles from E3D: http://e3d-online.com/E3D-v6/Extra-Nozzles/v6-Extra-Nozzle-Stainless-Steel-3mmx0.4mm

I have been in various discussions on plating nozzles and I might involve in that at some point in the future.

I would go for plated exchangeable nozzles like the E3D though rather than trying to plate the original heater block.

Link to post

Share on other sites