thanks david ! ill give it another try this evening, when my first print finished... :-)

Ian

thanks david ! ill give it another try this evening, when my first print finished... :-)

Ian

I printed small objects at 50mm/s on 225C which is on the low end for XT according to Colorfabb but still very milky. Otherwise it looks good. I also want to unlock the secret to transparency!!

Btw, the XT filament is not PLA but an "amorphous copolymer". Glass transition temp is 75C.

Daniel

Might transparency be related to cooling? Maybe less cooling? Haven't tried that though.

I've printed a few objects with the XT. I love it!

Stretchy Bracelet (CC BY-SA 3.0

Also printed a few other things in their other materials up on my blog.

I printed the bracelet at 234 at I believe 50mm/s. This was the second one that I printed. The prior bracelet was done at 225 and the layers delaminated. I'm guessing going a little warmer would get closer to being transparent, but I'm not sure you're going to be able to get truly optically clear with any 3D printed object due to the nature of the process.

1

1

The only thing im not sure about is... at the current settings, the glass transparent is coming out a little milky cloudy white....

I would love to get something actually transparent ?

Getting parts to be truely transparent probably isn't possible due to the layering. Printing with relatively thick layers (0.2) I think will look more transparent/shiny, opposed to very thin layer (0,08). The reason, I think, is with thin layers there is a lot more interference for the light to pass through, thus making it less transparent.

Another trick you could try is by increasing the flow to make sure the perimeter lines truely merged together as one. If there is a tiny gap between perimeter lines light will reflect of it differently.

The thing with XT is that it is truely neutral transparent, compared to natural PLA which has an yellowish tint to it. However you won't be printing glass panes with it.

Here is a neat trick with colorfabb_XT (also works on natural PLA). I put a large print in the dishwasher to see how it would cope with a temperature of 70C. When the machine was finished the part had turned a beautiful opaque white, sort of like the slightly transparent white ABS parts.

The sceltic skull printed in XT with 70C 'dishwasher' treatment, to its left normal XT, in back ground standard white & blueish white PLA/PHA (printed on Prusa I3)

Just out of frame is the Celtic Skull when it wasn't dishwasher treated, totally different!

I prefer the milky opaque white over the standard white and blueish white PLA/PHA. Something about the slightly opaque look makes it just seem so much better. For one the layering is difficult to see because shadow doesn't really show on the model itself. On te downside the Skull is still leaking a little bit of water, takes a while before it all gets out.

I'm going to put it in the dishwasher again tonight, see if it will turn a bit more white ![]()

1

1

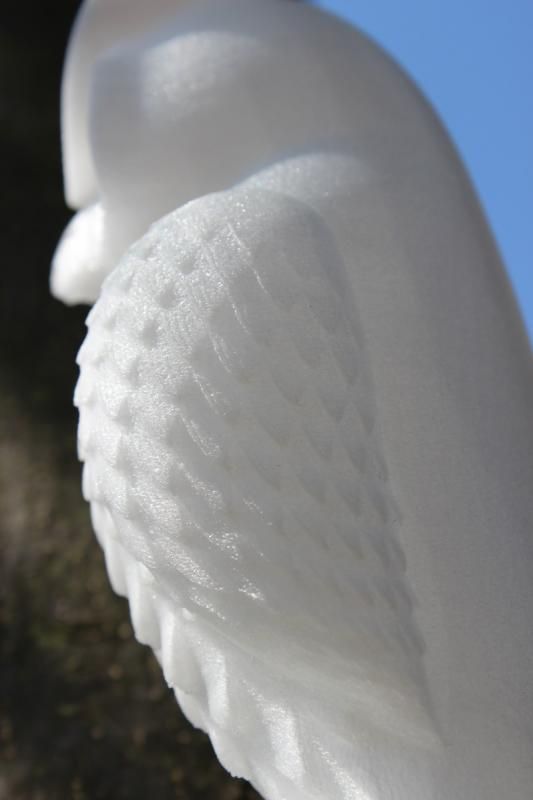

here is my first print with XT.

the colour is very milky and not transparent.... printed at 90 wtih temp 230...

but the quality is fantastic. printed at 0.06 layer and you just cant see the layer lines anymore...

also another verys nice thing about this new XT is, it gives a crystal white appearence.. this would look amazing for prototypes............. :-)

here is my first print with XT.

Wow! looks very nice. Now put it in the dishwasher! ![]()

Wow Ian. This owl looks fantastic. Was this your 25hr print? Colorfabb XT looks really nice, I guess that's on my list for the next purchase. Need to find a good dealer in Germany though.

This stuff is looking great... I saw a lot being used at Maker Faire and stupidly didn't try to purchase any on the spot...

... Is there a US distributor for it?

Hi Nick,

I'm the US distributor (http://www.printedsolid.com). I only have one sample spool of the XT myself ATM, but should have it in stock soon.

Here's the link for international distributors. http://colorfabb.com/resellers.html Nicolinux, looks like there are 4 in Germany.

Also, posted this in another thread, but the XT can be vapor polished for smoothing (like ABS), clarification (traditional application of vapor polishing), and some other interesting effects. http://www.printedsolid.com/vapor-polishing-colorfabb-xt/

has anyone printed it in lexan surface? - I do all my pla printing onto a thin sheet of lexan to get away from the blue painters tape and so far it has mixed results - some things pull away a bit (mostly they do not matter so i tolerate it) but then I am giving them very little area to stick with - but for 90% of what I print it is fab!.

The only definite is to apply a really thin layer of oil before the first print, or you will not get the part off!

Soft PLA sticks too well so I stick to blue painters tape for that.

The plus is that it is easy to have or 5 plates in rotation and you can bend it for awkward prints, but mostly they just pop off.

Will try XT on one over the weekend (thanks colourfabb - just got my 2Kg spool!) and see what happens!

James

@Nicolinux: the XT is listed here but not available at the moment? Just ask them ![]()

http://www.3dreamfactory.com/filament/colorfabb-3mm-0-75-kg/322/colorfabb_xt?c=90

I did, but my mail server was down for the last few days and I have missed their answer. I was looking for a sample pack including some colors and the xt. I'll ask again later.

Yo PrintedSolid! When are you getting in some XT that I can order? I'm jonesing!!! I need to print some clearish stuff!

Yo Nick! I can understand the jonesing. It's really good material.

Good timing.

My order is coming in Wednesday (verified with shipper). It is available for preorder now. http://www.printedsolid.com/shop/xt/colorfabb-xt-2-85mm/

If you're feeling adventurous, I have some samples of their new coarse woodfill material. It requires that the nozzle be opened up to 0.8mm. I can toss some in with any orders.

Ordered!!!! Thanks!

Hi All,

I was given a very small sample of XT at the 3d PrintShow in London last week, so I just got around to trying it. I printed a Yoda (my standard benchmark test) and I don't really have a lot to say about it, except that I'm quite pleased. It's very similar in appearance, feel, and flex to BendLay, but printed well the first time without too much fiddling. I've always had problems getting BendLay to extrude properly for some reason... One Yoda is not much of a test really but I loaded the material hit print, and a few hours later had a perfect Yoda bust waiting for me with no fuss. I think I might order a full roll of this stuff.

Cheers,

Troy.

What are people using for the build platform with XT? It sticks decently to blue tape, but I'm getting some curling when printing flat bottomed stuff. Would like to find something that it sticks to a little better.

As far as I can tell, I'm an outlier in the Ultimaker community...

I use a piece of plate glass clipped onto the acrylic. Coated with a few layers of Aquanet Hairspray (when I want a glassy bottom) or Elmer's Gluestick (when I don't care about the bottom finish and don't want to wait for the hairspray to dry).

I'm pretty sure colorFabb uses painters tape wiped down with alcohol.

I have noticed that as the weather has gotten cooler, corner lifting has gotten worse in general on the UM. I'm debating on getting something to use for a lightly heated bed (maybe like 50-55).

Wiping the blue tape down with acetone completely solved the problem without going too far. Thanks for the suggestion!

Acetone huh? I don't think I would have tried that out of fear of killing the adhesive on the tape and then just switching from plastic peeling off of tape to tape peeling off of bed.

Glad to hear it's working out well for you.

The Colorfabb looks really good!

I'm glad that Gijs (Houdijk) talked about it at the 3D hubs meeting ![]()

However, I first want to get to know my printer ( UM2) better before I go to other Filaments.

I am actually sad that there is no HIPS yet, It printed beatifully when shown at the 3D hubs! I also heard the fumes were not so good, but that needs confirmation.

Cheers!

Lennart

Doing my first print with XT right now!

It seems to print very well, printing at 245°C for now.

Can anyone explain about the "Dishwasher treatment"?

How about fumes from PET filament? Printer still sits right next to me while I'm trying out new stuff...

/edit:

Oh, and by the way:

Amy I supposed to use the fan or not?

Recommended Posts

Top Posters In This Topic

15

9

9

9

Popular Days

Nov 15

18

May 16

7

Oct 21

7

Aug 9

6

Top Posters In This Topic

hreedijk 15 posts

printedsolid 9 posts

jonnybischof 9 posts

chrisr 9 posts

Popular Days

Nov 15 2014

18 posts

May 16 2014

7 posts

Oct 21 2014

7 posts

Aug 9 2014

6 posts

Daid 306

Temperature does a LOT for transparent PLAs, experiment a bit with it, most likely you need a lower temperature. You can also play a bit with the flow, this also does things.

Link to post

Share on other sites