I have ordered a cubestick not to bad a price I tthought from here http://www.helpanyonecreate.co.uk/cubestick.html#

under a tenner

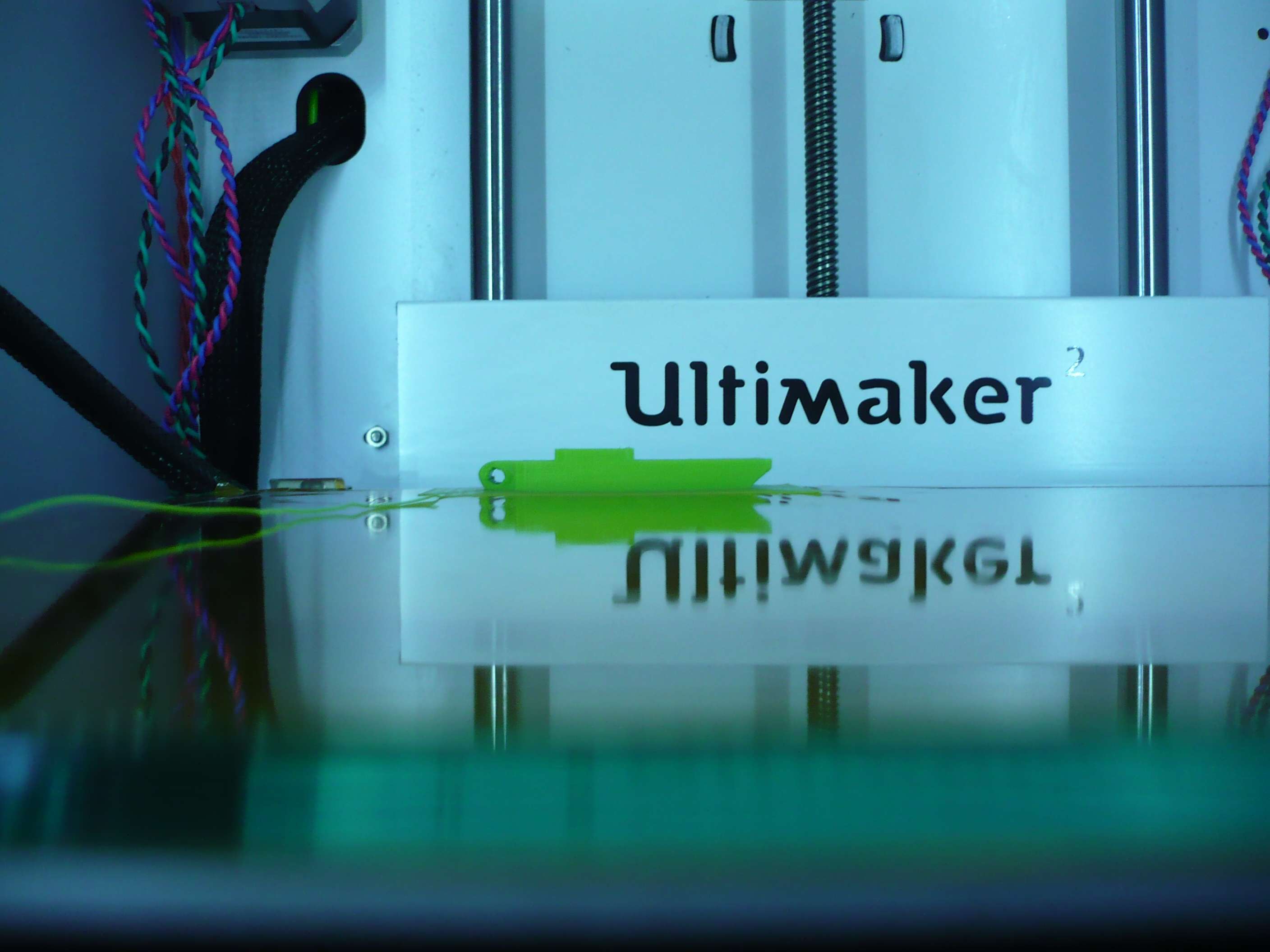

I still think that Kapton is still the better way to print with ABS ![]()

https://www.youtube.com/watch?v=tdAdWmQpd8U

But I never find it mentioned on answer... it's quite odd...

Seems you all like to clean the bed glass often and often after every print... getting rid of that sticking glue on it... anyway everyone have his own procedure to feel happy ![]()

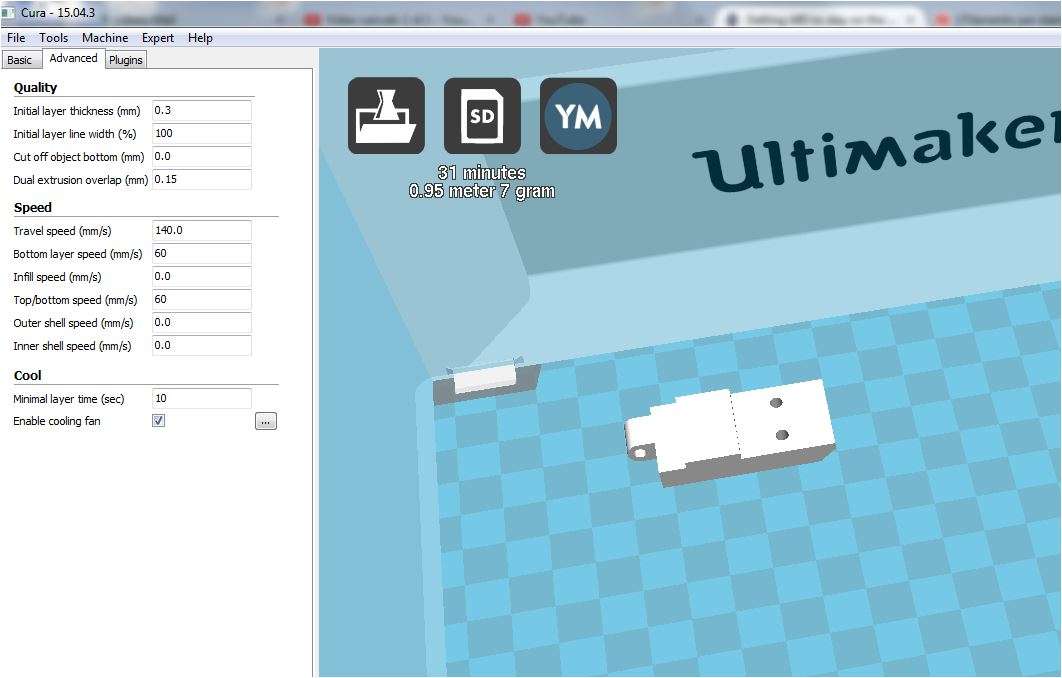

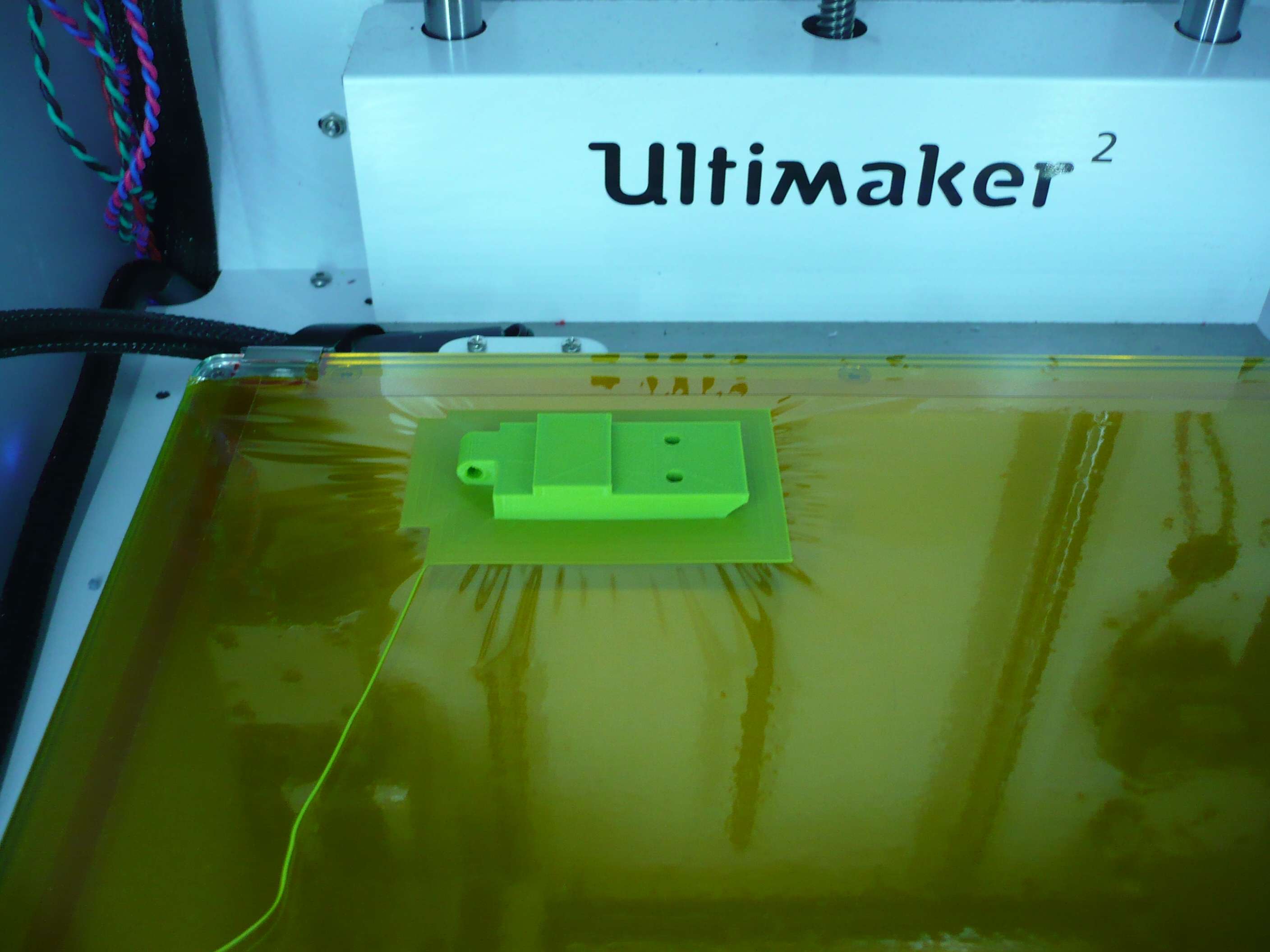

and this is some cheap ABS bought from RS

Printed at 240°C

Bed Temp 52°C

Speed 60mm/sec

Layer height .15mm

Brim 26

and finished ![]()

I still think that Kapton is still the better way to print with ABS

But I never find it mentioned on answer... it's quite odd...

Seems you all like to clean the bed glass often and often after every print... getting rid of that sticking glue on it... anyway everyone have his own procedure to feel happy

and this is some cheap ABS bought from RS

Printed at 240°C

Bed Temp 52°C

Speed 60mm/sec

Layer height .15mm

Brim 26

Thanks for the reply I was just using what I had to hand and it works just an option I am willing to try anything that works ![]()

cloakfiend 996

you can use washing up liquid to remove the acetone slurry very easily, as it softens the ABS very nicely so you dont even need to scrape. just cover it in washing up liquid and come back in a few minutes, and it will just wipe right off the glass.

-

1

1

Nice tip, @cloakfield. I use a stanley knife in a blade holder I printed from thingiverse. Scrapes all the leftovers in a couple of minutes. Being inherently lazy, I'm going to give your technique a whirl ![]()

cloakfiend 996

Regular fairy washing up liquid did it for me (the green one), but i assume they are all the same.....get it wet apply it and wash it off in warm water.

then just use a sponge and wipe it off. Zero effort for the lazy ![]()

Just a bit of an update

I have obtained Acetone Hairspray Kapton tape and Cube stick.

I have tried 3 times the kapton and hairspray without success the hairspary just lifted of the kapton ...............maybe wrong brand of hairspray just got cheap strong hold.

I tried the Cubestick and it worked first time

Acetone ..............maybe later if the cubestick runs out ![]()

Thanks all for your input

Edited by GuestJust a bit of an update

I have obtained Acetone Hairspray Kapton tape and Cube stick.

I have tried 3 times the kapton and hairspray without success the hairspary just lifted of the kapton ...............maybe wrong brand of hairspray just got cheap strong hold.

I tried the Cubestick and it worked first time

Acetone ..............maybe later if the cubestick runs out

Thanks all for your input

Hi ![]()

With the kapton tape you cannot have failed ![]() if you got any problem is due to the fact that you must clean the kapton with a paper towel wetted with acetone after you stuck it (the kapton...) on the glass bed

if you got any problem is due to the fact that you must clean the kapton with a paper towel wetted with acetone after you stuck it (the kapton...) on the glass bed ![]()

And it is not an optional it is a must to clean the surface before print on it, to remove any trace of grease ..

Your problem will be after the print .... because on kapton tape, ABS get stuck as hell ! ![]()

Another way can be use a sheet of kapton but it is nice for big print but not for small ones :(

With big print it's almost impossible to remove them from the print bed if you use kapton tape but with a sheet like in the photo above you can just remove the print with the kapton attached to it and peel it away as easy as turn a page of a book ![]()

ah! Kapton must be used alone.... and well cleaned (read degreased) with acetone ![]()

-

1

1

thanks I have been reading of differnt ways of using the tape and your description is another ![]() .

.

Thanks for sharing your experience.

I do favour the cubestick method it is simple and took no effort to do just smeared the gluestick on the glassplate and away I went, with the Kapton I had to ensure it stuck down with out air bubbles etc...... but still failed but if I get stuck I may try it again. I now have the materials for all methods to hand now ![]()

You can easily put the kapton with water. You need to spray some water to get the glass slippery so you can adjust, then with a soft squeegee you can get rid of the water and the air bubble.

If you can, avoid to use pla on the kapton. It sticks too much and it can be hard to get the pieces without damaging the kapton some times.

Edited by Guest-

1

1

You can easily put the kapton with water. You need to spray some water to get the glass slippery so you can adjust, then with a soft squeegee you can get rid of the water and the air bubble.

If you can, avoid to use pla on the kapton. It sticks too much and it can be hard to get the pieces without damaging the kapton some times.

Ah OK so I can apply same as I do with vinyl nice and thanks for coming back I think I will order a second glass table makes life easier.

merci bien

Edited by GuestI'm always amazed by how much time and effort and expensive kapton people put into bed adhesion, while ignoring the excellent inexpensive solution that UM provides: glue stick.

In my experience any glue-stick brand intended as a office or school paper adhesive will work fine - you can easily get a dozen prints with the same application of it, and it washes off easily when you want to refresh it.

Glue stick works perfectly with PLA and ABS. If you ever have a print that won't come off easily after cooling, either stick the build plate in the freezer for a few minutes, or soak it in the sink overnight.

If a print won't stick with glue stick, you probably need to reset the bed height, not fool around with messy stuff like hair spray, or rough-surfaced blue tape.

Edited by GuestI'm always amazed by how much time and effort and expensive kapton people put into bed adhesion, while ignoring the excellent inexpensive solution that UM provides: glue stick.

In my experience any glue-stick brand intended as a office or school paper adhesive will work fine - you can easily get a dozen prints with the same application of it, and it washes off easily when you want to refresh it.

Glue stick works perfectly with PLA and ABS. If you ever have a print that won't come off easily after cooling, either stick the build plate in the freezer for a few minutes, or soak it in the sink overnight.

If a print won't stick with glue stick, you probably need to reset the bed height, not fool around with messy stuff like hair spray, or rough-surfaced blue tape.

Im afraid I have had NO success with the prittstick it just curled off when printing ABS great with PLA and my table is set correctly.

The Cubestick with ABS is excellent works everytime.

Regular fairy washing up liquid did it for me (the green one), but i assume they are all the same.....get it wet apply it and wash it off in warm water.

then just use a sponge and wipe it off. Zero effort for the lazy

I really have to thank you for that tip, because this morning I was removing a print using my trusty stanley blade scraper and managed to cut myself quite badly. I ended up in hospital and needed several stitches.

When I got back I soaked the buildplate as per your instructions, and after a few minutes the ABS juice came off as a film. No idea if the soap is necessary, so I will give it a whirl with just hot water next time. No more scrapers for me!

Glue stick works perfectly with PLA and ABS. If you ever have a print that won't come off easily after cooling, either stick the build plate in the freezer for a few minutes, or soak it in the sink overnight.

I have printed many kilos of ABS and tried hairspray, two different brands of glue stick and of course the vaunted ABS juice. In my experience ABS juice works really well for PLA, is an absolute must-have for ABS, and works really well for nylon as well.

Applying ABS juice is simple if using an ABS puck - you only need a really thin film.

Removing prints can be pretty hazardous as per my previous post. In the past I have also used the freezer trick, which takes around 15 minutes or so. PLA and ABS come right off once the plate is frozen or really cold. @cloakfield's method seems to be the second-fastest, very rapid (approximately 5 minutes and no elbow grease involved) so that will now be my go-to method until something even faster and lazier comes along. Nylon (specifically Taulmann Bridge) comes off like magic. Once the plate has cooled to around 30C, it simply peels off with the gentlest tug.

cloakfiend 996

I've only had success with abs juice for ABS. PLA for me needs just the glue stick. the one it comes shipped with is fine, although alternatives last longer on the glass.

Perhaprs it's only my "bad" thought but...seems that someone have some particular interest on pushing glue-stick vs. kapton ![]()

1) Kapton and glue-stick are both good for ABS... BUT:

2) Kapton can manage multiple print; if you pay particular attention almost """"infinite"""" as Kapton doesn't change shape, don't make any dirty, don't attach to your print head, don't attach to your printed object

3) you have not to make any realign of your bed after each print

4) you have not to clean your bed after each print!!

5) it is not as expensive as you tought! AMAZON

6) you don't waste your time cleaning your bed (some repeated I know ![]() ) and realign it!!

) and realign it!! ![]()

7) the printed surface in contact with Kapton is as smooth as glass ! ![]()

Now glue-stick:

1) works fine with bot ABS and PLA... BUT:

2) can manage ONE print.. two or three if you are REALLY LUCKY ![]()

3) it's not uniform and your printed surface is UGLY!! ![]()

4) you have to clean it out and the best way is to remove your bed glass and rinse under warm water

5) every time you clean it and re-apply you MUST realign your print-bed

Glue-stick it's cheap Vs Kapton?? NO WAY ![]()

Both method let you print ABS ... choose what you like more ![]()

P.S.: for me Kapton Rules ![]()

https://www.youtube.com/watch?v=u4qxr7-TtAs

Edited by GuestPerhaprs it's only my "bad" thought but...seems that someone have some particular interest on pushing glue-stick vs. kapton

1) Kapton and glue-stick are both good for ABS... BUT:

2) Kapton can manage multiple print; if you pay particular attention almost """"infinite"""" as Kapton doesn't change shape, don't make any dirty, don't attach to your print head, don't attach to your printed object

3) you have not to make any realign of your bed after each print

4) you have not to clean your bed after each print!!

5) it is not as expensive as you tought! AMAZON

6) you don't waste your time cleaning your bed (some repeated I know

) and realign it!!

7) the printed surface in contact with Kapton is as smooth as glass !

Now glue-stick:

1) works fine with bot ABS and PLA... BUT:

2) can manage ONE print.. two or three if you are REALLY LUCKY

3) it's not uniform and your printed surface is UGLY!!

4) you have to clean it out and the best way is to remove your bed glass and rinse under warm water

5) every time you clean it and re-apply you MUST realign your print-bed

Glue-stick it's cheap Vs Kapton?? NO WAY

Both method let you print ABS ... choose what you like more

P.S.: for me Kapton Rules

I dont have any agenda regarding methods of adhesion I only stated the ones I have up to now that I managed to get to work.

If I can get kapton to work for me then I will use it.

The best methods are the ones easiest for me to use and currently it is glue sticks but if I need to use another method then I will I dont care what method I end up using as long as I get successful prints.

When my second glass plate arrives I will revisit the Kapton route and follow the advice given...........if it fails to work for me then I will continue with the gluestick but if it works I am happy to stay with the tape.

PS I dont know why you have a bad thought and think someone has a particular interest in pushing glue sticks...........

Edited by Guestcloakfiend 996

@ieol2015...... you must be using the wrong type of glue stick or something as i disagree with all of your comments when it comes to glue sticks???

With PLA I use a certain brand of glue stick and it lasts many multiple prints, I.e. around 10 to 20 before it needs to be added or re-applied, and I NEVER re-align my print base and always get perfect bottoms on the prints.

Just because you take the glass plate off, doesn't mean you need to realign everything! thats madness. I take of the plate everytime but never re-align!

I've only used that Klapton tape once, but feel that the only people who are using it are simply using it as they have not mastered printing with glue stick. or lack a heated bed and are forced into using it for something, as it most definitely not quicker to apply and re-apply than glue, and wont give any better results than well applied glue either and the bottom is as flat as the glass plate with NO BUMPS! and the gluestick is cheap as dirt and lasts almost all year.

There are bumpy glue sticks and there are smooth glue sticks. Obviously use the smooth one. Problem solved. No need for tape ever, unless you are going down the ABS route that is, but i don't so with PLA you just dont need it.

Edited by GuestIt really takes hundreds of prints to get extremely good at a technique. I tried kapton on aluminum heated bed for about 20 prints. I would often tear it - didn't do enough prints to get really good at it. I could not get two adjacent strips perfect together and so would get a line on the bottom at the seam. But I was pretty happy with kapton.

I've done more than 100 prints on glass with PVA glue and I prefer that. I can use the same glue for about 5 or 10 prints without re-applying. With glue stick the bottom is messy unless you dilute the glue with water and spread it until it's invisible. With hairspray it goes on pefectly thin but you have to waste some tissues to keep hairspray off the printer (spray tissue, spread glue). My favorite is wood glue mixed with 10 parts water, brush it on with paint brush. Dry to invisibility. hairspray, gluestick, wood glue - all are PVA glue.

Recommended Posts

ultiarjan 1,223

I just use "cubestick" glue for ABS, bed at 100celsius, works fine ....

Would still like to find out what type of glue it is so I can replace it for something cheaper and easier to get ...

Link to post

Share on other sites

paulmag 1

Hi I had the printer set for PLA table at 60deg to start and when I changed to ABS changed the temperatures for ABS using defaults 260 for the head and 90 for the table.

The lines are wavy from me messing them when I removed it.

I dont know how much ABS I will print the project I have demands it but the consumable parts for the printer are not expensive.

I dont think its a perfect solution but for a weekend fix using what I have to hand it works just fine

Link to post

Share on other sites