Hi Gijs,

Can you tell us how this compares (flexibility, toughness, shearing strength, impact resistance, etc) to ABS? Also to Taulman 618 (Nylon). How is the warping and shrinkage on this material? Does it improve with a heated bed? also what is the adhesion to blue tape like?

I've been printing quite a bit in the 618 lately and it's a great material but the warping is very difficult to manage.

Thanks,

Troy

Recommended Posts

owen 19

Hi Gijs

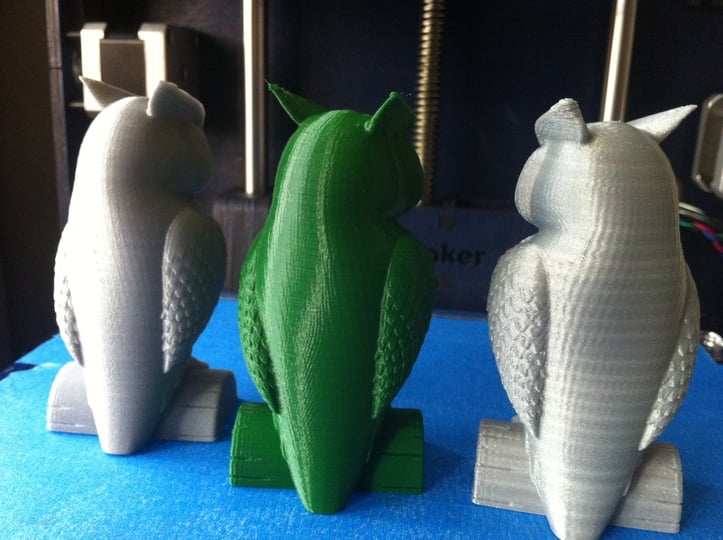

Looks good.

Is the temperature it goes soft at the same?

Link to post

Share on other sites