A couple of things, could you supply some images and print settings? Those usually help others with suggestions. Essentially you posted a comment in a forum where others are very willing to help, but you have given them very little to go on.

A couple of things, could you supply some images and print settings? Those usually help others with suggestions. Essentially you posted a comment in a forum where others are very willing to help, but you have given them very little to go on.

In my opinion and through experience, the only reliable support functions of Cura are Brim and Touching Buildplate. All other options are terrible. I realize this does not help you with support for items that need support in between parts already printed to compensate for bridging, but some objects just need to be re-assessed on how they are orientated for the print.

Every print I have done using Brim and Touching Buildplate has come out pretty much perfect. All supports are very easy to remove and discard.

I also have had lots of problems with support structure.

and had to resort to pliers and saw to get support removed and damage details or the whole part in the process.

especially support inside the object are almost impossible to remove without some tools and damage the part :-|

and I also had to resort to make my own support structure because Cura just wont add support in certain areas or too much,

I really hope the old and easy to remove support structure comes back as an extra option in Cura PLEASE DAID !

I think the new support system works great for flat bottoms, but for sharp/weird pieces (which is usually when we need to use supports) it is super unpredictable.

I still have cura 13.03 installed for this purpose where it does the zigzag supports which actually works quite great for some objects.

Maybe try and download legacy cura and see if it gives you better luck? It would be cool to have different support methods selectable in the future.

Cura is free software, and being actively developed, but certainly not perfect yet, I'm afraid. You may want to just use a different slicer such as Kisslicer or Slic3r - both free - or others have said the support capabilities of Simplify3D are very good - but that's commercial software.

Alternatively, as noted above, why not experiment with Meshmixer's support capabilities instead - semi-intelligent localized support is probably a better option.

Also, don't forget to preview your gcode in Cura and/or Repetier Host before you print, to make sure it's going to do what you want it to.

Cura is free software, and being actively developed, but certainly not perfect yet, I'm afraid. You may want to just use a different slicer such as Kisslicer or Slic3r - both free - or others have said the support capabilities of Simplify3D are very good - but that's commercial software.

That all very nice answer, but the support was working good in the older versions, and now it's "less" then good.

so because it's getting worse we should just use other software ?

normally software is supposed to get better, and unforeseen faults fixed, but Cura support is getting worse compared to older versions, and how many versions had trouble with free flying support and certain parts not getting any support at all, this was not the case with older versions.

Cura might be the best and fastest slicer on the planet, I gladly choose slower rendering with good support, then throw away the part after hours of printing :(

the support was working good in the older versions, and now it's "less" then good.

I think Daid's newer support is of the mindset where you print with a second extruder something soluble such as HIPS. I think UM might come out with an official solution some day this year.

But for people like you and me using only PLA, what to do?

Well the old Cura still works great:

http://software.ultimaker.com/old/

Version 13.04 is the newest version with the old slicer.

Personally I like meshmixer, although it's not perfect:

http://www.extrudable.me/2013/12/28/meshmixer-2-0-best-newcomer-in-a-supporting-role/

pay particular attention to how to rotate your part in the "annoyances & limitations" section and also note that there is a small error where he set layer height to "0.5" mm and it should be the layer height you print at e.g. .2 or .1mm.

That all very nice answer, but the support was working good in the older versions, and now it's "less" then good.

so because it's getting worse we should just use other software ?

Well, my point was just that you are free to use whatever software you want to use. Cura is financially supported by Ultimaker, but there's nothing that specifically ties Ultimaker users to Cura. If you don't like how it works, then yes of course you should use something else.

The old version of Cura that had 'better' support used a totally different 3rd party slicing engine that was slow, mostly unmaintained, and un-maintainable, and had plenty of bugs of its own. The new Cura slicing engine is much better in lots of ways, although the built-in support options still need work - and Daid, and UM, are well aware of that. In the meantime, there are plenty of other options, and it only makes sense to look at those. The field of FFF printing is still evolving rapidly; no one workflow or set of tools has all the answers for every type of print. I certainly hope and expect that Cura's support-generation will improve before too much longer, so that Cura can provide the best possible user experience; but there are plenty of other options available.

And as I pointed out, there are several options for previewing gcode to make sure that it performs as expected - there should be no reason to 'throw away a print after several hours' due to major defects in the gcode; those can fairly easily by detected just by looking at the layers view, and making sure that you have all the support that you want.

I also firmly believe that extensive support generation is simply not the right way to go when using a single extrusion head; there are too many issues separating the support from the model itself; the Meshmixer approach offers far more control and a much better surface finish, so I highly recommend exploring that.

and my point is that I used to use Cura as one stop to print, no hassle, just open the drawing make your adjustments have it make support and print,

now I have to sift through hundreds and maybe thousands of layers (big prints) to look for possible problems, and you have to really concentrate to look for those faults, and are very difficult to spot sometimes.

the speed for the fast slicing is lost, spending 20 minutes sifting through the layers :(

And I still don't get what is an improvement for support, (old) being able to pinch between two fingers and remove the support structure without any major force, instead of (new) having to use pliers and other tools with considerable force ?

so as Cura improves in the future you will be forced to use more then one software packet to get your object printed ?

that's what you are saying !

Don't get me wrong I am very much impressed what Daid has done with Cura, the speed of slicing is amazing, but how long ago was that changed, and when did Daid really start looking at the faulty support that has been a problem for quit some time now, Daid is probably doing important work on Cura but for now it seems support is not high on the priority list, and I think it should be.

I hope Daid could answer why the old support was changed and when we will be able to get good support (not just this year answer)

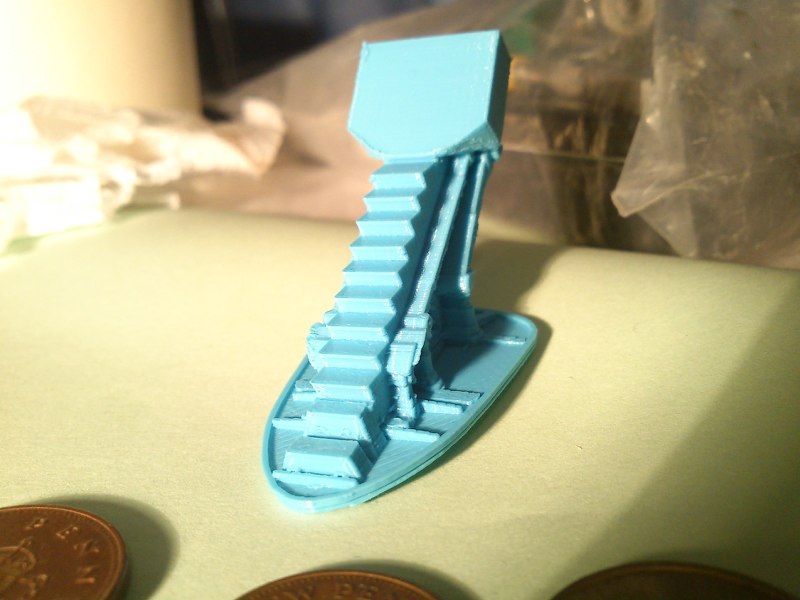

oh look. it failed again.

one more failed print, and i think it will be a case of a new listing on the ultimaker for sale section.

i am literally printing what is essentially a Table with 2 very fat legs. nothing more, nothing less. the problem is the support structure wont support the area that needs support (similar to what Vlacrow posted) and the areas that are way less than a 40 degree angle, it decides to start burrowing into the moles in the model, and filling gaps, so its impossible to get the support structure out, and when you need to start putting nuts and bolts in there, it makes it almost impossible to get out.

i mean c-mon ultimaker, you can print this:

but you cant print this?!?!? REALLY!?!?!:

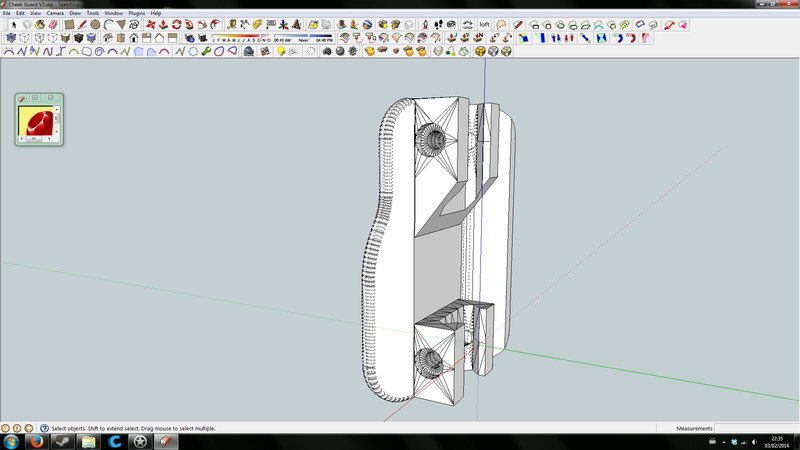

i even tried flipping it up on its end to see if that helped, and it still randomly filled in the screw holes when i didn't want it to, or when it didn't need to, so of course that didn't work either

the worst par though, i have one sitting right here on my desk. and I'm using the same settings, and it just wont print again.

i just don't get it. working planetary gears, detail sculptures, complex space ship parts, it all handles like a dream. a flat bed on top of 2 rectangles though. oh no that's far too complicated.

what basically happens is the support structure gets too close to the part and just welds itself to the base of the model, and then in the indents in the "clips" its all to hasty to get the support structure wide again for the flat overhang, so therefore welds itself inside there as well, and then it pushes into the nut and screw holes, and its all just a disaster.

i was there with my scalpel trying to slice away at the structure, but it was stronger than my actual print. and as its an engineered part, i cat adjust any of the wall thickness's or it wont fit.

have i really been defeated by this, this pieces? this pieces i could make by hand out of 2 pieces of wood? thats what i dont get and what frustrates me the most. oh no a 1:100 scale replica of a ship from the most detailed game ever, no problem but this. urgh. why!?!?

-------------------------------------------------------------------------------------------------------------

EDIT:

so well i have had to once again, design something around traditional FFF printing. was hoping that support structure would save me here, but no. :(

yay to ugly prints :(

"so well i have had to once again, design something around traditional FFF printing"

Well... yeah, that's what you have to do when the printing method used by Ultimaker (and 99% of all other hobby printers) isn't capable of printing things the way you would like. You don't use a hand drill to make holes in concrete do you?

"i just don't get it. working planetary gears, detail sculptures, complex space ship parts, it all handles like a dream. a flat bed on top of 2 rectangles though. oh no that's far too complicated."

Yes, that is too complicated since it targets the main problem with FDM printers, they can't print in mid air (not well, at least), that's just the way it is. That's where support comes into play and yes, sometimes it doesn't work all that well because of the limitations of the technology. Maybe you didn't quite understand what it was you were buying?

That said, the problem with support being printed inside the holes could be because you selected "support everywhere" instead of "touching buildplate".

The new support seems to work really well in certain circumstances, like big pieces, the whole thing comes clean in one piece. And terrible in others like gaps and holes for more organic or precise structures. Cura 13.03 had the exact opposite problem. Large pieces would take ages to clean and rip off in pieces, but small holes (even 2mm radius) were easy to tear off with tweezers. So choose your poison I guess. It'd be nice to be able to switch between the two algorithms since if you opt for the older algorithm, you don't get like 6 generations of advances for the rest of your print.

I was going to suggest turning it on it's side, but it looks like you did that already.

I don't think there's really any way around it without going for dissolvable supports or an entirely different printing method altogether which would cost... a lot.. right now. But I get your frustrations.

What is it anyway? rail covers? handguard?

The reason the old support method went away was because it was inextricably bound up in the old Skeinforge based slicer. Once Cura ditched Skeinforge (which was old, crap overall, and impenetrable) that necessarily meant getting rid of the code that generated support. And with everything else that's gone on in the last few months - such as the need to create firmware and slicer support for the UM2 - Cura development has been a bit slower. So support generation isn't all it could be at the moment - especially in very complicated cases like this.

None of this is anything to do with the printer itself - these are very challenging prints for FFF printers of whatever brand. The available solutions are either to go with a totally different technology, or design the parts to be less challenging prints, or try a different (equally free) slicer and see if that works better for this particular print. Or, consider using something like meshmixer to add your own support.

I don't see the point saying that Cura doesn't meet your needs, and then refusing to consider alternatives software that might be better in that case. There are a lot of things that Cura is already great at - I've gotten some fabulous and very challenging prints from it lately. I firmly believe that it will get even better and better in the coming years and months - but in the meantime if it doesn't meet your needs, just look at other programs.

Hello,

I also noticed this problem support. :oops:

I tried several solutions without réelement found my happiness.

Case 1: I used Blender for the file .stl ... I got some things but not completely easy to implement. Often too small to medium load, or, still its not clever positioning. :roll:

Case 2: Cura. On mechanical parts, except to get rid of the rough side, it works not too bad but if you want to stay smooth, it must use other solutions. :smile:

Case 3: I use meshmixer and if there is no kept totally witdth and height, it is a good idea. I regret that meshmixer wrong place the object. I would love better positioned to make my print. It even happens on some mechanical parts no support is possible. :roll:

No one of the three solutions is satisfactory for me.

My idea :idea: :idea: :idea:

Maybe should another external program developed by the community. He would take care to allow to create bowling supports. Take a stl file. Add the pins. Export to a new stl. Go through Cura and print.

Good day

I'm well aware of the support structure problems of Cura 13.06 and 13.12.

Any Cura version of 13.06 or higher will not properly support some things. This has to do with the algoritm used for support material. Which is "look at the angle of the polygons, and if it's more then 60deg, add support. This generally works for organic objects, but fails for the case that Valcrow shows.

Cura versions 13.12 or higher uses a newer "grid/outline" support structure. Which is in some cases far superior, as it breaks away as a single chunk. (I've had great results with this) But for some other cases does not work very well.

Cura versions 13.06 to 13.11 with the line supports do not properly implement a gap between the support and the model. This is fixed with 13.12.

I'm planning to add an option for the zig-zag lines again, as this works better in some cases.

Note, support material is very tricky. There are many things you need to account for. And I've never been happy with any implementation so far.

(0235: That last picture should print fine. The filled up screwholes is a bug, which can be worked around by disabling the fix-horrible-type-A)

that final picture is the one that i am having to use after modifying it so it can print without support structures.

sorry if i got angry, but it has quite literally been every single day (except Saturday, i was of shooting up The Embassy in Leicester XD) trying to print this thing. i took holiday Thursday through to today specifically for time to 3D print and it hasn't worked.

yes the new support structure does just peel of nicely in one big chunk, if it wants to come off in one big chunk without taking the rest of the model with it.

everyone puts a lot of work in and sometimes its all too easy to just blame everyone else, not realising that they do are a person :(

anyway :

@IRobertI - that's what confuses me so much. i knew i was buying the second highest (after the UM2) Z axis 3D printer, PERFECT for model making, which is why i got it, but for it to get stumped by this just eludes me. also it was determinately on touching buildplate. the support structure just angled off into the gaps. its hard to explain.

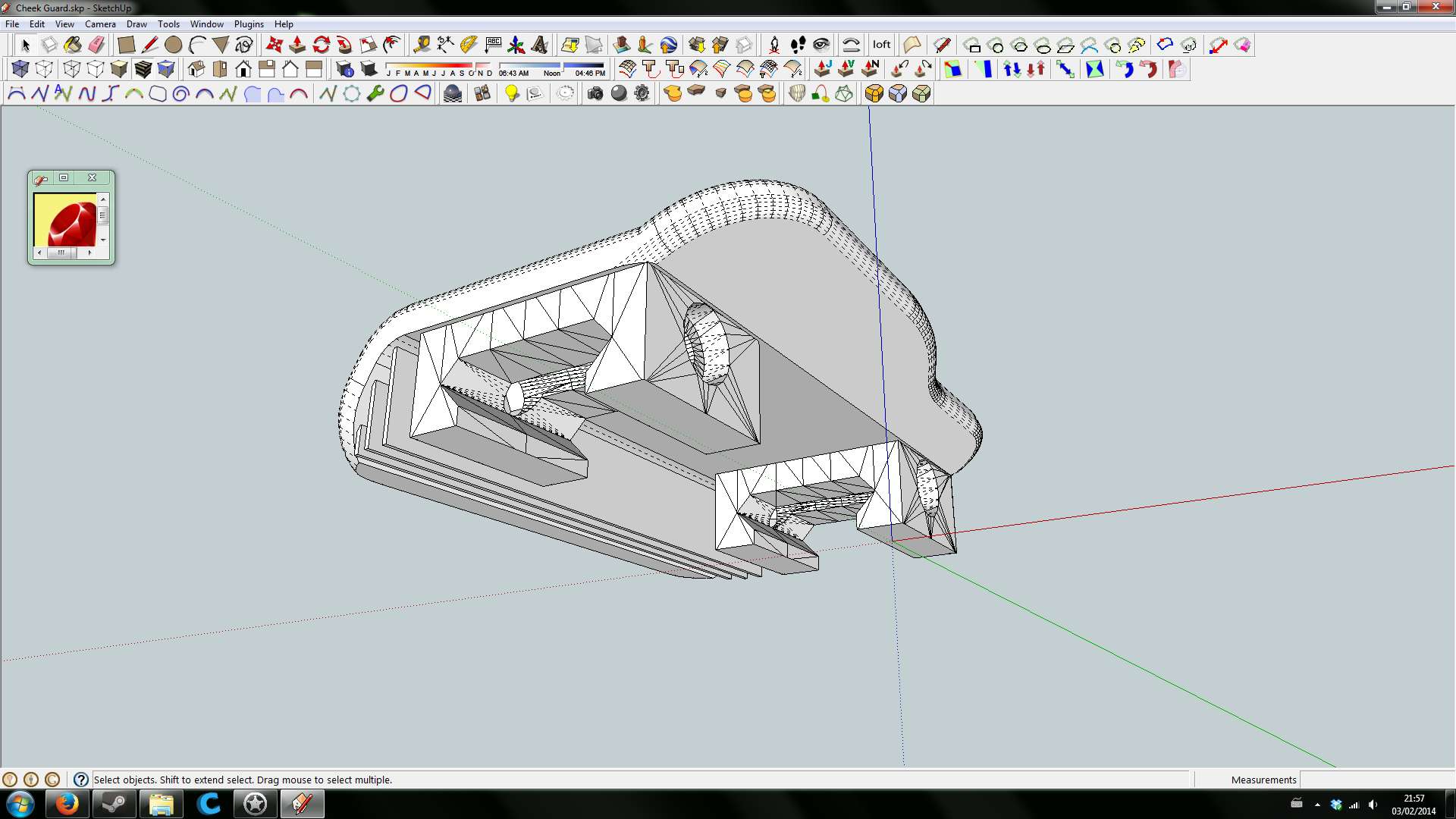

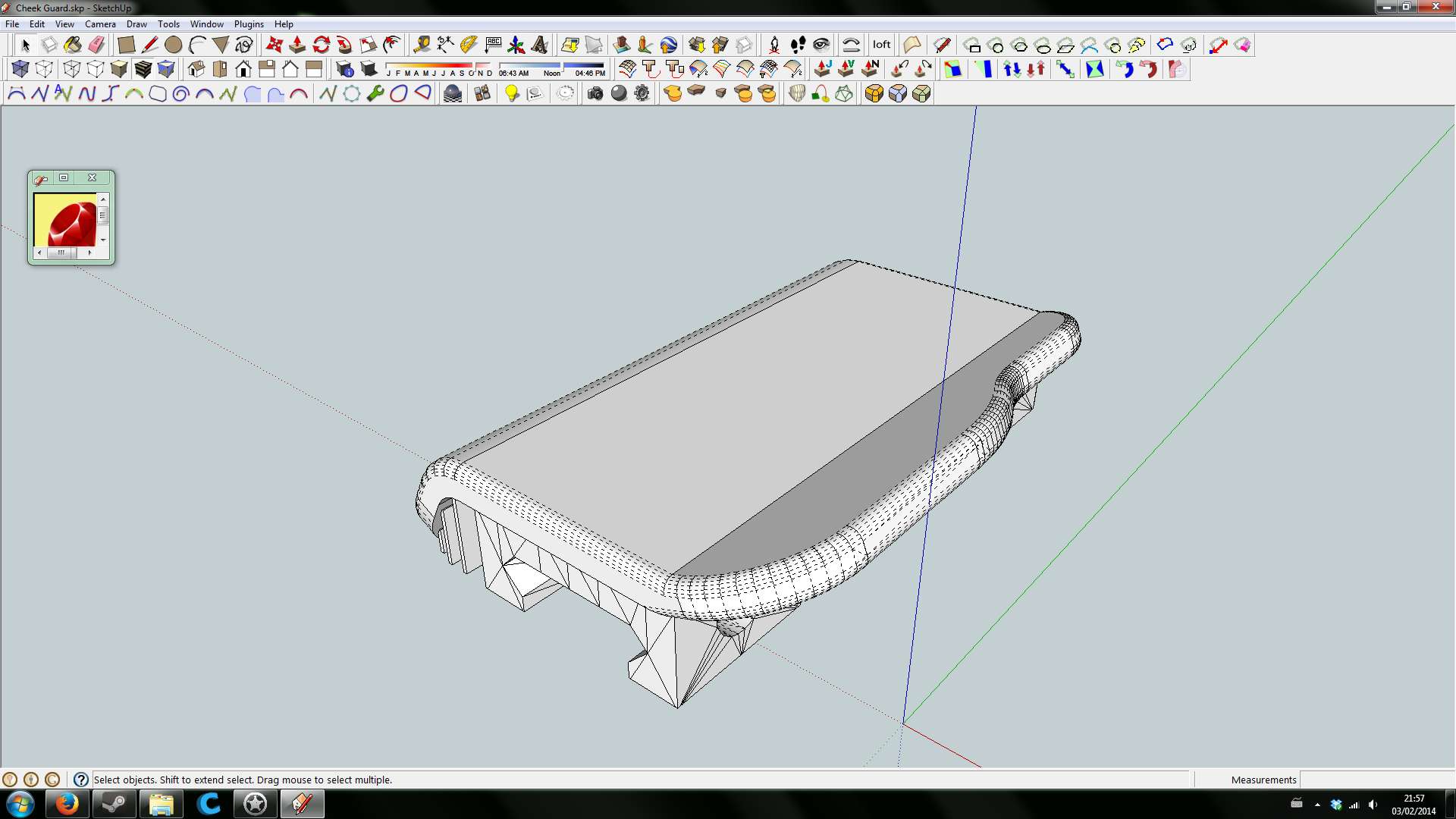

@valcrow - good spot, its a cheek guard for my gas rifle, so i don't get a blast of ice cold propane to the face ![]()

@illuminarti - as harsh as it sounds, if i paid for ultimaker, i want my software to be ultimaker home grown. i have tried Kisslicer and that was like looking at a wall of 1's and 0's. there is a reason i use sketchup ![]() (seriously? no smiley face with a dunce hat?)

(seriously? no smiley face with a dunce hat?)

@Daid - Cura is pretty awesome for everything but support structure ![]() that's another reason i went ultimaker as Cura was just drag a piece in, move it around, scroll through all the layers etc. i just await future updates

that's another reason i went ultimaker as Cura was just drag a piece in, move it around, scroll through all the layers etc. i just await future updates ![]()

I think it will be great when Cura can do everything, and do it really well. It's not there yet, but I think it has the greatest chance of getting there, of all the free slicers. But it's not there yet. I'm afraid that it's just the nature of the technology at the moment that you need to understand all the 1's and 0's - certainly if you want to do difficult things with it and get good results.

As another thought - would it be possible to split your original design into two pieces along the plane of where the flat part meets the brackets? That would allow you to print that part flat on the bed, and require almost no support. You could add some tabs to help mate the two parts together, and then either glue or screw the two parts together.

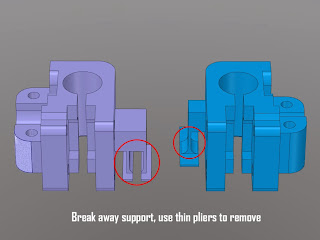

Personally, I think the simplest solution by far for all people who design their models themselves, which you obviously do, is to model your own break away support in the model itself. That way you have perfect control over everything and it literally takes a few minutes of your time (depending on what app you use for modeling obviously).

Agreed Chopmeister. What do you suggest to create? Should I add a support of 1mm2 for every cm2? I wouldn't know what would be sufficient as support, but sure would like to try...

I use thin plates of material, twice the nozzle radius, so in our case 0.8mm, which have a wider base so they adhere to the platform better. To really understand how they affect various prints it's best to do some trial objects and see for yourself.

I rely heavily on bridging while doing this, so you must see how your printer performs to get optimal results. Here's a simple example of my supports:

This method does have limitations, primarily if you're focused on having pretty downskins. But then again, other methods don't produce pretty downskins either, do they? ![]()

On the rare occasions I do my own support - I tend to do the exact same thing - rely on bridging - only support the outer edge on flat surfaces.

The most difficult thing to support are *almost* flat surfaces that tilt upwards. Like under someone's chin on a statue. For those I tend to support left and right side of the chin. Or do zero support as the UM2 is pretty amazing. The surface will be rough but it will usually work.

So basically I do what chopmeister does.

But most of the time I use meshmixer which does an incomplete job of support (support points instead of support lines) but they break off extremely easy.

I've had tall prints that have very tall support structures fail because the support was a simple tower. On tall parts the tools need to do an aspect ratio calculation and see if they can build a pyramidal structure to support the high overhangs.

A simple tower is not sufficient.

Alternatives can be adding towers at intervals that attach to the design. This way the support is supported by the printed body which will give it more structural integrity. Eg, add a bridge every 20mm in Z if possible or do something algorithmicly to solve this. Maybe a diagonal at 30 degrees to the support tower from the body with small attachment/bindings to the body?

Edited by EE_guy

Recommended Posts

Dim3nsioneer 557

Support material and support techniques in FFF (fused filament fabrication) are indeed a never ending story, I think. And many results are everything else than satisfying. So I can understand your anger having invested quite an amount of time.

When I started with my Ultimaker I did one or two tests with the Cura support structure with awful results and large difficulties. So I decided this is not the way to go.

In the meantime I had some very nice experiences with the Meshmixer support. If you don't know it yet, this thread might interest you: http://umforum.ultimaker.com/index.php?/topic/3880-meshmixer-20-a-better-way-to-generate-support

However, don't expect a one-klick-solution, this software still needs some tweaking. But there is a real chance to get a reasonable result.

For a real one-click-solution I see only two possibilities without having actually tested any of the two:

- support with a soluble material such as PVA

- using a different 3D print technique such as e.g. SLS/SLM

So why are there not more innovative solutions for support structure in FFF? I think the patent situation is quite critical concerning support. Large companies have issued patents which block some very interesting developments. So I guess Cura has to focus on solutions which are non-critical in terms of patents but also very rudimentary...

Link to post

Share on other sites