Yup 😁

kmanstudios 1,120

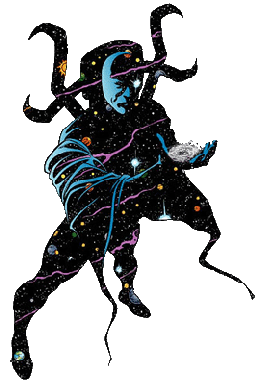

This is a prelim test of the character "Eternity" from Marvel comics.

Illustration ^^^^^ (not mine)

So I started to make my own 3D version. I am trying to keep the 'graphic' quality by painting in false hilites. This is just a test and I will be doing more before I print the full sculpt (about 17" Tall.

Still trying to figure how far I can take the paint job to try and keep the spirit of the character.

-

2

2

- 4 weeks later...

A coworker asked if things for his H0-scale trains can be 3D-printed. I made some demo parts for him. Came out better than I expected, the bridge is printed with a new brand that I never used before, so not that nice, but the other ones turned out good.

-

4

4

- 2 weeks later...

I think that bridge came out quite well too. A bit of cement-color paint in the grooves, and a bit of stone-like paint overall, and it will look great in the landscape. I have seen far worse bridges in HO-landscapes. :-)

- 1 month later...

GregValiant 1,252

I had a decent sized "N" gauge layout that I worked on for 25 years and it would have been nice to have the printer then.

I don't post a lot of things but I'm supposed to know what I'm doing. This was for a friend. I thought the "glow in the dark" windows were a nice touch. (The gold stripe on the body was a necessity else it would have been an Italian flag instead of the Mexican flag.)

-

1

1

- 3 weeks later...

Working on anatomical models.. experimenting with smoothable filament.

Guess what it is.

UM S5, 0.15mm layers. White Polysmooth. Break-away support.

Postprocessing:

- some light sanding. 420grit. (across-layers)

- first smoothing: DIY Alcohol-smoothed (25mins). Paintbucket with soaked towels. 2 days of outgassing.

- some minor detail correction with knive and sanding papers.

- second smoothing: Sprayed some more alcohol on problem spots.

conclusion:

more sanding = better

too much alco-smoothing at one time = detail loss

The alcohol takes forever to evaporate out of the plastic.. apply modest heat and consider holes in your part so parts insides can evaporate the solvent faster.

The longer the part stays sticky the more dust it can land.. a dust reduced drying place is important.

- have a polysmooth-slurry ready to fix any holes. 🙂

Edited by yzorg

-

3

3

Looks good, great result!

But what is it?

19 hours ago, yzorg said:Guess what it is.

13 hours ago, Smithy said:But what is it?

haha I didn't dare to make a guess 😄

-

1

1

4 hours ago, SandervG said:haha I didn't dare to make a guess 😄

I am sure it is not that what it looks like 😁

cloakfiend 995

I think I know what it is? Is it the ladies fun part?

-

1

1

- 2 weeks later...

cloakfiend 995

well done! I've to make a similar piece. No matter where I try to suck up the rubbish, the nozzle is a tiny bit too large. This is why we have the printers. Just reliziing an idea and get a problem fixed.

-

1

1

Vacuum cleaner tip: excellent idea. Now I need one too. Just never thought of it...

Concerning the anatomical model above: I always thought the "thing you think it is", had a sort of *ring* around the inner tubing? But I don't see any ring here? So I am wondering if it really is that thing we think it is? Or is it something else instead, like inner-ear structures, or glands, maybe the one at the back of the brain?

Edited by geert_2

-

1

1

cloakfiend 995

Ill just say it. That is a model Clitoris 100%. Just google clitoris model and you'll see, maybe with some other bits the vulva or something but in that general area. Looks well printed kinda looks like bone. I thought it was the inner ear at first but why would someone post that as we've all seen it loads in biology books....so must be something naughty! Lol.

Edited by cloakfiendGregValiant 1,252

I'm putting sliding barn doors in the archway that leads to our bedroom (yes, it's true...I'm married) and they require a 19 x 19 slot in the bottom edges of the doors for a hidden roller guide. Typically I would have designed it, gone out and picked up the supplies, and then spent an hour or so fabricating it. I was never absolutely sure that I'd gotten the center of the guide to coincide with the centerline of the router.

This took about 1 1/2 hrs to print. It would have taken MUCH longer to go to the store, buy the supplies, and cut, drill, glue and screw to get it together. The monetary savings was significant as well.

For those of you who don't recognize it, it's on the plunger base for my 50 year old Porter Cable router. I did refine the design for the regular base as the assembly is much lighter (for an old man to hold up while he works). It worked as planned and the slot is indeed 19 x 19 and is centered in the doors.

-

1

1

On 8/13/2021 at 3:48 PM, cloakfiend said:No acetone on this one for a change!

What happened, I hope you are well and everything is fine! 🙂

-

1

1

This Ferris Slip On Case was 3D printed in black ASA filament on my Voron V2.4 recently.

Model designed by MelindaBireknstock on GitHub.

A few more pictures in our 3D print gallery.

-

1

1

Hi, form my project "automatic shutters" I have studied a motor gearbox very cheap and the case is printed with S5 in CPE+. https://youtu.be/B2EWamvndWk

In the same time I have modify the baby motor with two motor and a new battery pack with lithium cells, but one of gear in a gearbox was broken and I trying to print it with technical different material, but in final I did a mix with a print gear and a metal gear. https://youtu.be/WH3fH85vcqo

- 1 month later...

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

Top Posters In This Topic

362

282

221

179

Popular Days

Jan 5

30

May 12

26

Jan 13

23

May 1

22

Top Posters In This Topic

ian 362 posts

cloakfiend 282 posts

skint 221 posts

SandervG 179 posts

Popular Days

Jan 5 2014

30 posts

May 12 2014

26 posts

Jan 13 2014

23 posts

May 1 2014

22 posts

Popular Posts

kmanstudios

Took me forever to do this. And it is still rougher than I would have liked. 3D concept rendering: Finished piece:

kmanstudios

I just finished this. It was a multi-part print for ease of painting. Some of it I am not sure what happened...but hey, it is purty....And, I am unanimous in that ? Test Render Parts

gr5

Bath interferometers. I have made about 20 of these for people who use them to test their telescope mirrors. They are amazingly accurate and can do better than a $40,000 Zygo PSI optical tester. Th

Posted Images

jsw 19

Yes, gr5 pegged it! One of the people on 'another network' suggested I put a model DeLorean on a street to the left of the building, but I'm not that much of a BTTF geek. 😉

I do have another BTTF reference on the theater in a row of facades on the table edge.

Link to post

Share on other sites

Labern 774

Today I printed a reverse camera holder and plastic welded it into the number plate light cover.

Link to post

Share on other sites

Smithy 1,144

Nice! For the caddy?

Link to post

Share on other sites