@LeoDDC - That looks like it's going to be a nice print. What do you plan on doing with it?

Cheers. Just doing it for fun.

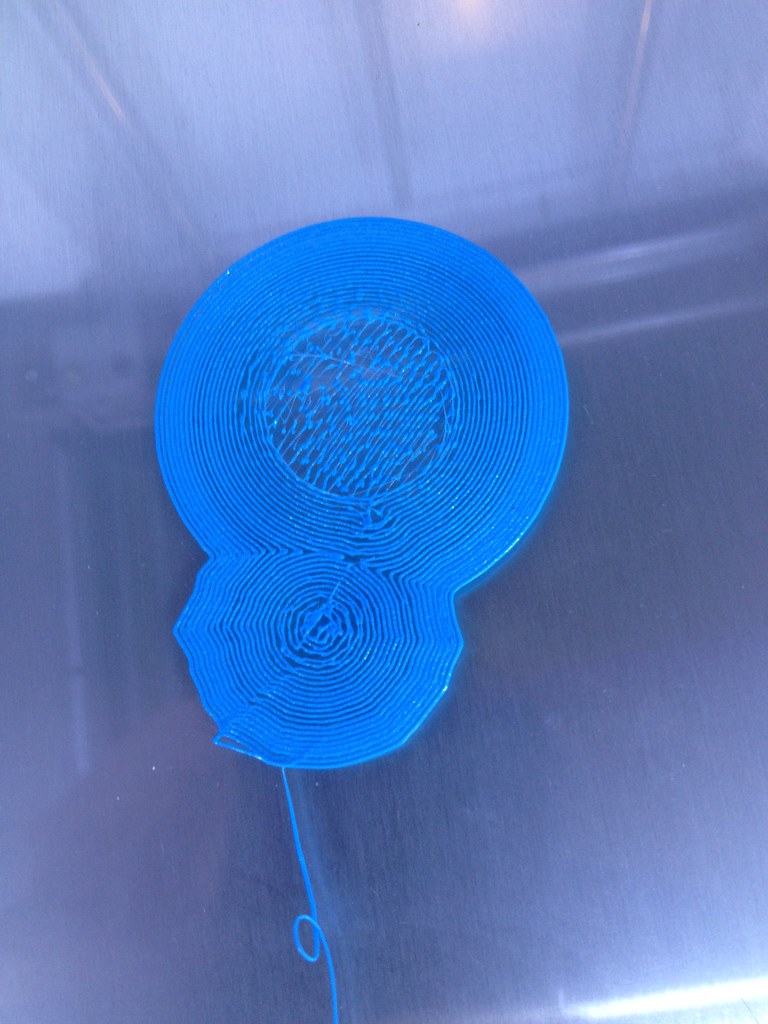

I had a problem with the bowden tube moving around but fixed it. Then I had a problem with the print because of some internal overhangs so I changed how I was going to print the model to avoid this. I finally started printing and it was looking good until about 15 hours in I noticed some massive under extrusion. Unfortunately I had to abort the print. Now it barely extrudes any material at all. I think there is probably a blockage it the nozzle but I don't know how to fix it. I've tried several material changes and I've tried heating the nozzle up to 260C as per the trouble shooting instructions but nothing seems to work. :(

This blue brim was printed at 260C.

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

Top Posters In This Topic

362

282

221

179

Popular Days

Jan 5

30

May 12

26

Jan 13

23

May 1

22

Top Posters In This Topic

ian 362 posts

cloakfiend 282 posts

skint 221 posts

SandervG 179 posts

Popular Days

Jan 5 2014

30 posts

May 12 2014

26 posts

Jan 13 2014

23 posts

May 1 2014

22 posts

Popular Posts

kmanstudios

Took me forever to do this. And it is still rougher than I would have liked. 3D concept rendering: Finished piece:

kmanstudios

I just finished this. It was a multi-part print for ease of painting. Some of it I am not sure what happened...but hey, it is purty....And, I am unanimous in that ? Test Render Parts

gr5

Bath interferometers. I have made about 20 of these for people who use them to test their telescope mirrors. They are amazingly accurate and can do better than a $40,000 Zygo PSI optical tester. Th

Posted Images

jonnybischof 60

Very interesting stuff! The original Dremel workstation is completely useless (stiffness? inexistent...). Hope you got it working better...

/edit:

Finally got around to making some pics of a print I did

I'm currently making an E3Dv5 printhead. First iteration doesn't fully work yet, but it's quite the accomplishment for me. This is by far the most complex construction I've done until now so I'm happy it fits at least partially

The part is printed with Colorfabb XT. Very nice material for this purpose! It evens out most of the low-res curves and makes the part quite strong.

Link to post

Share on other sites