Thanks for taking the time to relate your experience! I think this will be very helpful to a lot of people ![]()

Post your latest print!

I have a lot of the same experiences, the clogging of the nozzle, flexibility, temp.

I have a lot of the same experiences, the clogging of the nozzle, flexibility, temp.

before I start I clean the nozzle with a acupuncture needle, thin enough pierce through the lump in the opening to get the material to flow.

the material is more flexible than pla, I had to adjust the screw of the filament feeder (v1) a lot more, the failure on the photo was because it did not have the right tension. Hopefully that will be solved with extruder drive v2....

the second failure became loose from the tape..

it is very nice that the layers almost disappear, compared to the same settings with pla, see photo

i really like how the creators say that this new material wont warp on a standard print bed !

thats really cool !

Ian

http://3dprinting.com/materials/3d-prin ... elieve-it/

here is some thing I printed this morning.

Print time 40 minutes.

speed 100

temp 230

That is true. I noticed absolutely no warping with my wood prints. I usually always have some small amount of warping with PLA, but this stuff stayed perfectly flat and stuck well.

PeggyB: That second picture looks great! It's like it's carved right out of wood. I found the lead of a 1/8W resistor was the perfect size to fit in the nozzle to clear it.

Cheers,

Troy.

i really like how the creators say that this new material wont warp on a standard print bed !thats really cool !

Ian

http://3dprinting.com/materials/3d-prin ... elieve-it/

Im starting to get good at printing! im so happy with print quality i just have to play with settings more to get better speed! here is some projects ive been working on.

this one is going to be my next project!

Hi adamrw91

I like the looks of that fan thing. I was wondering what it's for and what did you slice it with?

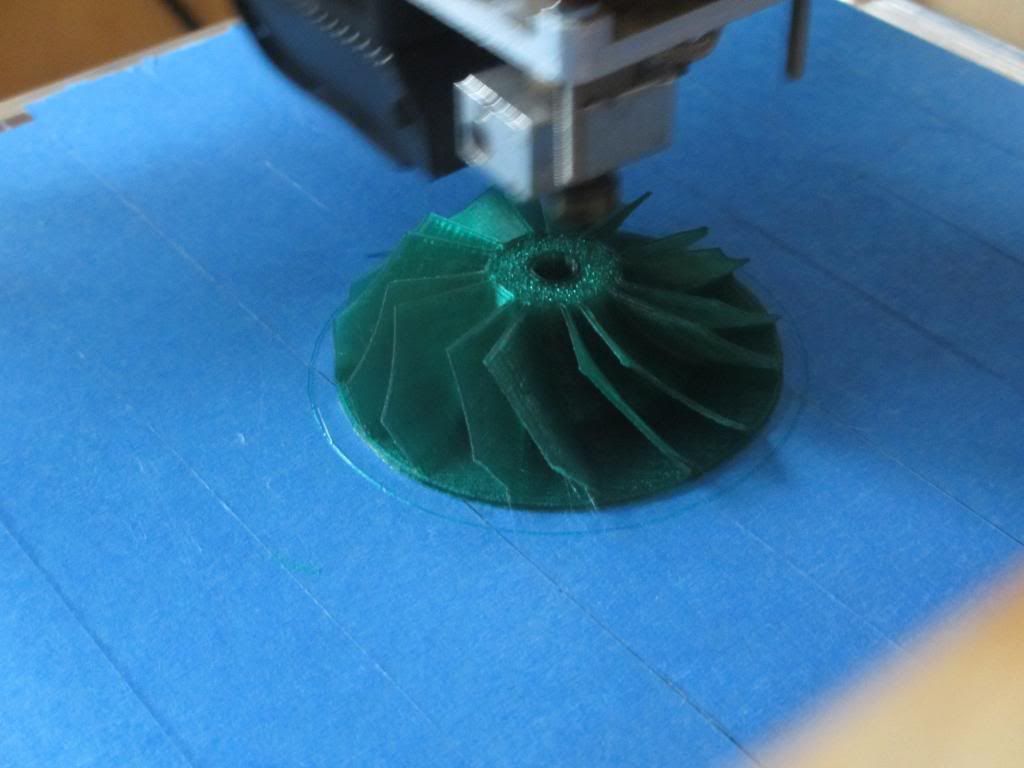

that fan thing is a turbine that you can attach to a dremel! here it is

http://www.thingiverse.com/thing:13188

Im planning on adding a reducer and a tube so i can use it for dust removal

wouldn't be spectacular or exciting, except for the fact it's printed on my UM out of NYLON.

the first piece (middle) I had too close to the bed, the nozzle was burning the blue tape and I didn't get enough nylon on the first layer for the second to stick to, so it curled off (at which point i stopped the print)

2nd piece (right) I had better adjusted, and by the 3rd piece (left) I had it perfected - check out the flexibility on this fully waterproof one way valve.

the slight burning marks are residue of PLA left over in the nozzle which doesn't like being heated to 260C and occasionally splats out and makes a mess. it will be gone soon.

where do you get nylon filament?

ebay, local hardware store, garden center..

but don't try it if you have a V1 or V2 hotend, the plastic parts won't take the heat. you'll want to upgrade to an all metal hotend first.

I wanted to see, if my Ultimaker is able to print really small parts. So I designed a micro dumper.

It is 25 x 20 x 17 mm small and fully operational. ![]()

You can find the STL-Files here:

http://www.thingiverse.com/thing:32773

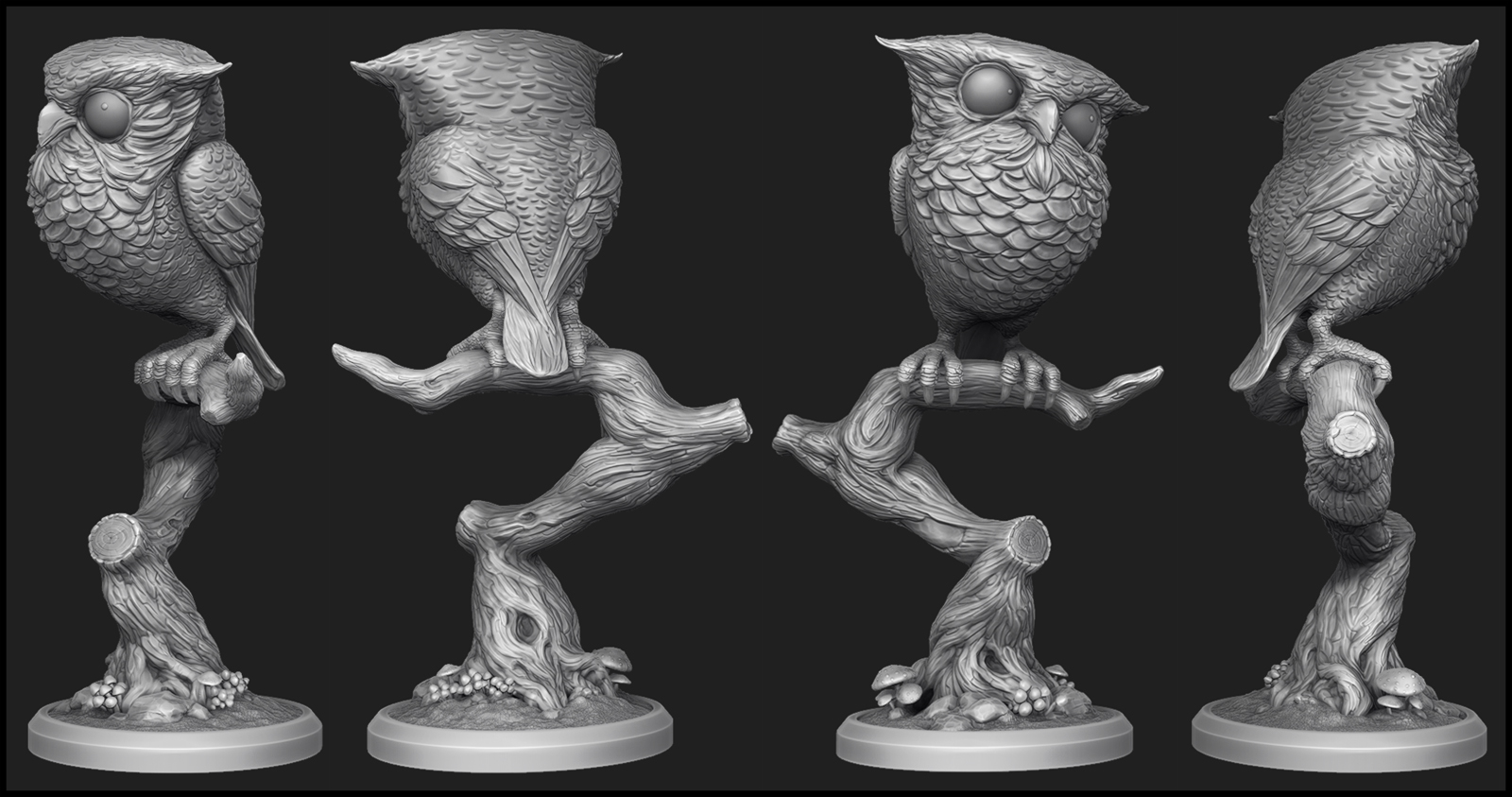

Here is a print I did for a friend a while ago, just getting around to posting it now ![]() It was modeled by my friend in Zbrush and printed with cura/printrun.

It was modeled by my friend in Zbrush and printed with cura/printrun.

oh woww that is amazing !!!

can you please please please but that on thingiverse as a STL.

I would love to try and print it..... :-)

Thank you.

Ian ![]()

you printed that without support?

tis very impressive, the microdumper i liked too.

so going home now. and first thing i will do is kiss my girlfriend and then start up my ultimaker.

lets see guys what coolness can we produce this evening !

Ian ![]()

so going home now. and first thing i will do is kiss my girlfriend and then start up my ultimaker.

Better than the other way 'round (kissing the Ultimaker.... ) :mrgreen: :mrgreen: :mrgreen:

so going home now. and first thing i will do is kiss my girlfriend and then start up my ultimaker.

Better than the other way 'round (kissing the Ultimaker.... ) :mrgreen: :mrgreen: :mrgreen:

dont laugh, !! some men get big problems because they talk in there sleep.... oh MARY............

who is mary is the normal answer ...

But when I sleep, oh ULTIIIIIIII :lol: :lol: :lol:

................ slap !!!

i really love my ultimaker.

i did this with still no belt tighteners on. since i had big problems with over heating motors, i downed the voltage and now they are so cold, you can keep your ice cream on them, as it prints....

and i know, i realy should belt up my home printer now....

Ian ![]()

![]()

one more fresh printed...

print time.... 30 minutes... ![]()

![]()

![]()

Ian ![]()

from the little castle above, what software do you think is being used here.

i know if i put together for example the rocks first, then built the castle and placed it in the correct position, all points where the rock solid and the castle would intersect. would create negative unprinted zones and would completly screw up a print ....

or they are carving it. ?? using one solid mesh and then twisting, pulling and cutting (bolean) until they have the form, that would guarentee a one piece complete printable mesh !... but be a bomb of work....

curious.........

Dutchmogul uses Tinkercad mostly, with some other tools afterwards to tweak and add fine details.

At Ultimaker we have the world in our hands now!

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

Top Posters In This Topic

362

282

221

179

Popular Days

Jan 5

30

May 12

26

Jan 13

23

May 1

22

Top Posters In This Topic

ian 362 posts

cloakfiend 282 posts

skint 221 posts

SandervG 179 posts

Popular Days

Jan 5 2014

30 posts

May 12 2014

26 posts

Jan 13 2014

23 posts

May 1 2014

22 posts

Popular Posts

kmanstudios

Took me forever to do this. And it is still rougher than I would have liked. 3D concept rendering: Finished piece:

kmanstudios

I just finished this. It was a multi-part print for ease of painting. Some of it I am not sure what happened...but hey, it is purty....And, I am unanimous in that ? Test Render Parts

gr5

Bath interferometers. I have made about 20 of these for people who use them to test their telescope mirrors. They are amazingly accurate and can do better than a $40,000 Zygo PSI optical tester. Th

Posted Images

codemaven 0

Well, my main issue was that I had to print faster. It needs more experimentation to determine the actual parameters, but it appears that it melts as low as 170 degrees on my extruder, and works fine as high as 245. However the binder in it is somewhat oily and if you let it sit in the hot-zone too long it appears to evaporate away, forming a hard lump of wood that will not extrude. I've found that the extruder must continue to run while it's hot. If you leave it for more than about 30 seconds without moving some filament through the extruder then the nozzle will plug. If you leave it long enough (a minute or so) you end up with a charred mess. I had to remove the nozzle and clean it out inside with a wire a few times.

It also tends to ooze more than PLA, even at low temperatures. It's like there is no glass transition, it goes straight from solid to liquid without much of a "soft" zone that I can see. I don't know what the binder is, but it also feels oily when the part is warm so it's more like a wax than plastic.

Another interesting thing that I noticed is that the part feels oily and very flexible to me after it's finished, even when it's cool... But after about a day (or at least 8 hours later) that oily sensation goes away and the material feels more solid. It's almost like the binder needs to settle, cure, or evaporate away.

My experience with it is very limited so far, I've only managed two successful prints (the Maple leaf and the Yoda) so my observations could be way off base. I'm looking forward to hearing reports from other users. This is a very cool material.

Cheers,

Troy.

Link to post

Share on other sites