Holy s*** thats sexy

Oh, and the STLs are available on YM.... pom pom pom. Think I found my new project (after I get that baby mobile finished for my godchild) ![]()

that's very impressive! a lot of work in that, each part correctly oriented too, looks great!

Sneak peak for my UM bros!

Printed on the UMO.

More pics.

http://www.redicubricks.com/3d-printed-ducati-1199-superbike-on-the-ultimaker/

And yes, model is shared on Youmagine.

DidierKlein 729

:eek: :eek: My god this is some sexy printing great job, i love the pics too. I went on your website and checked the pics... the first pics show the real one and the model one. Your pics are so nice that i got confused and thought the printed version was the real one :mrgreen:

And yes my Bronze T-800 needs a better finish, i have to get my hands on some proper polishing stuff, but i also like the less shiny effect it looks a bit like a rusty head you'll find in the garbage in a couple of years when machines have taken power in our world

Really insane project, this is going to be made in the winter by me!

Thank you Valcrow for sharing!

Wow! Thanks for sharing ( and thanks for giving the link before I could)!

I'd love to se the "manuals" for making the different shapes!

I had to adjust the thickness though:

for Colorfabb XT I only printed 2 layers of 0.4 mm. three is waaaay too tough.

for glowfill also 2 layers, but remember to put material flow to about 133% (on normal settings, I do not remember what normal flow is in mm/s), so the sheets are flexible enough.

They would indeed, with the new colored XT from ColorFabb they won't break as fast as PLA.......

See above, XT is too tough when too thick. Also use pritt/glue! XT tends to not stick to the glass buildplate ( at least on UM2)

Sneak peak for my UM bros!

Printed on the UMO.

More pics.

http://www.redicubricks.com/3d-printed-ducati-1199-superbike-on-the-ultimaker/

And yes, model is shared on Youmagine.

WOW! AMAAAAYZING ( crocodile)

How on earth...

how much time did it cost you?

Cheers!

Thanks guys! :mrgreen:

@braddock - Yeah the orientation (and combination) of everything was the toughest part. The tail section was particularly head scratching.. I ended up making it in 6 pieces all in weird angles, but it worked out in the end.

@Didier - That's the work of my bro the photographer. I'm not a fan of how the official Ducati bikes are lit, it's really weird and flat looking, almost fake like you said...

@cons - I fixed it! thanks!

@Lennart - It took me about 2.5 weeks (including painting), I had a bit of an insane 2.5 weeks since this was my side project. I had to make sure I was pretty much always printing even if the parts attached to it wasn't designed yet. Then foolish me, I went to try enamel and lacquer paints which take like days to cure (I'm use to instant dry acrylics). I assembled while paint was still curing on the insides. :oops: soooo. I can't guarantee all the pieces will work perfectly.

It was fun anyways. ![]()

Wow! Thanks for sharing ( and thanks for giving the link before I could)!

I'd love to se the "manuals" for making the different shapes!

I had to adjust the thickness though:

for Colorfabb XT I only printed 2 layers of 0.4 mm. three is waaaay too tough.

for glowfill also 2 layers, but remember to put material flow to about 133% (on normal settings, I do not remember what normal flow is in mm/s), so the sheets are flexible enough.

See above, XT is too tough when too thick. Also use pritt/glue! XT tends to not stick to the glass buildplate ( at least on UM2)

My settings are the first layer of 0.3mm, 2 layers of 0.15mm...

I also use an heated bed and kapton tape on my UM1, XT (transparent and colored) does indeed not attach well on glass without glue.

Hello there,

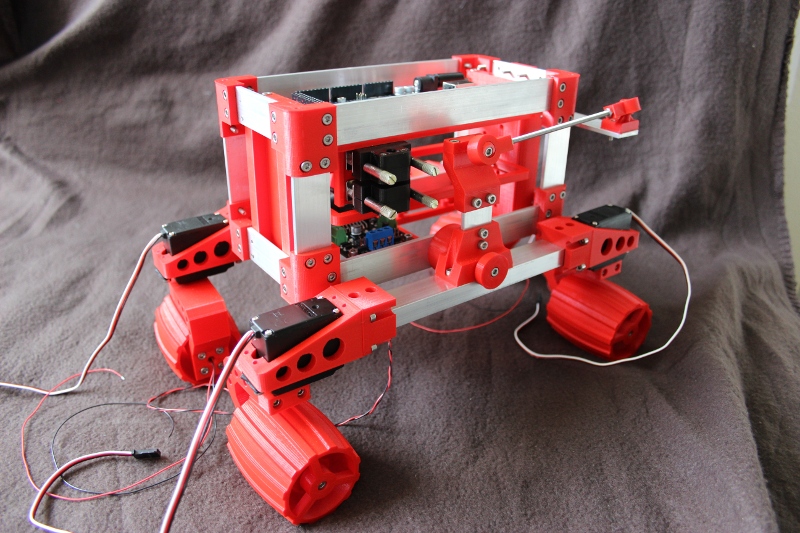

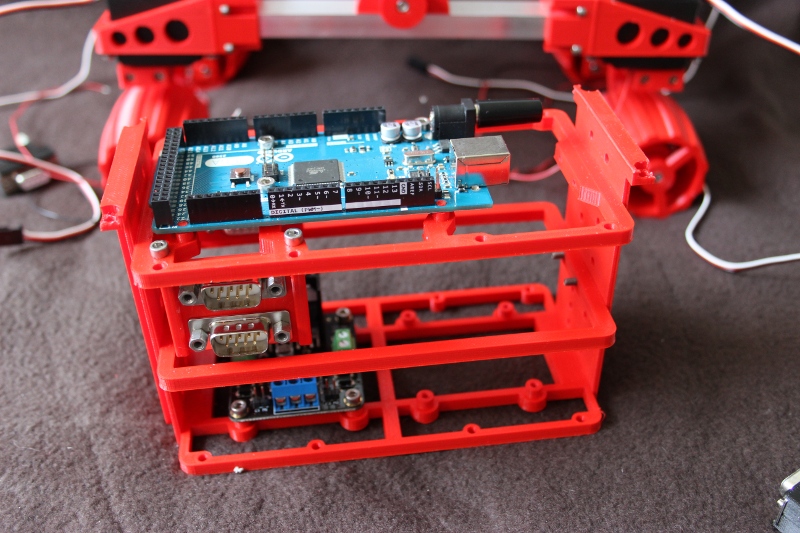

And counting. Here it is the integration within the structure. Now you can see the circuit boards and development being gradually.

At the level of the chassis.

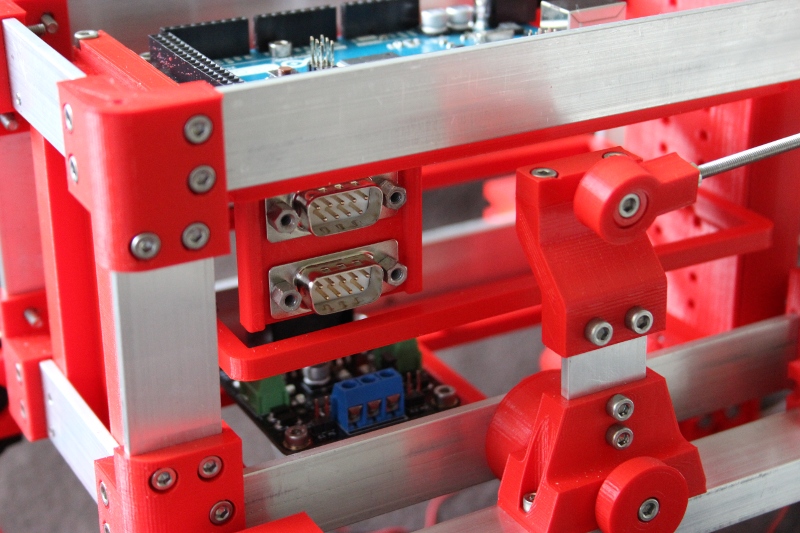

In terms of power outlets.

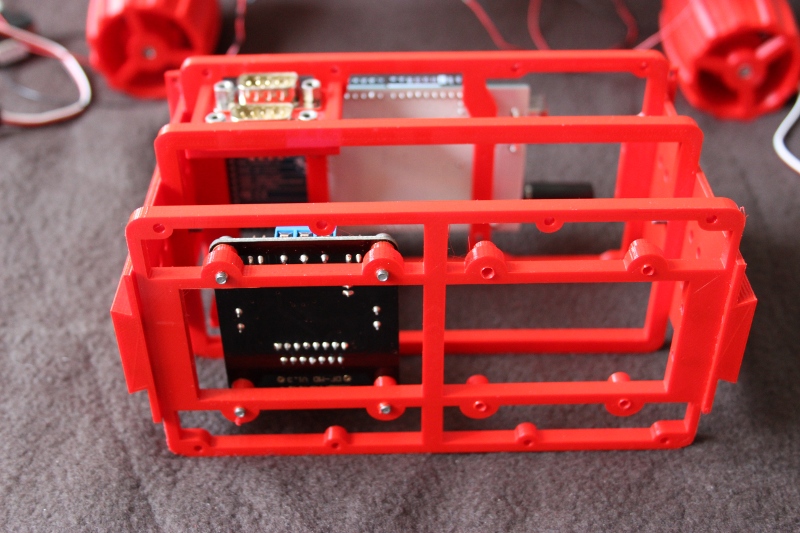

The rack removed.

The bottom of the rack. Here I would lodge the battery over its entire length.

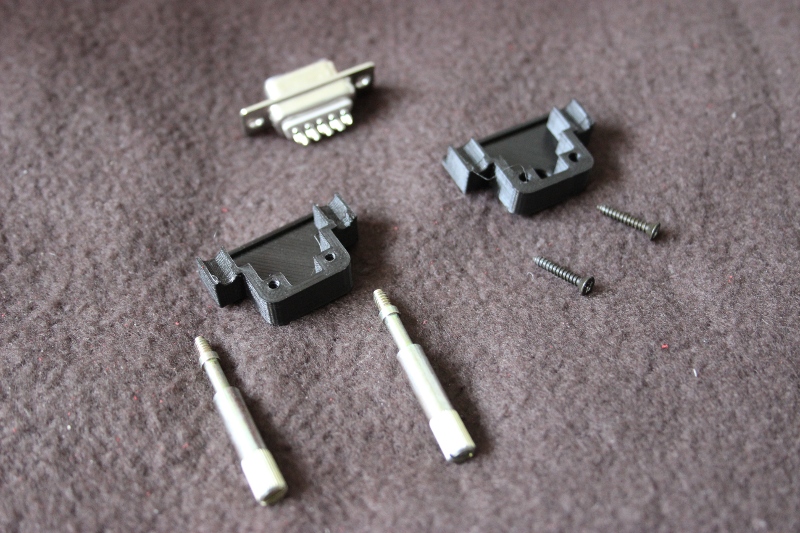

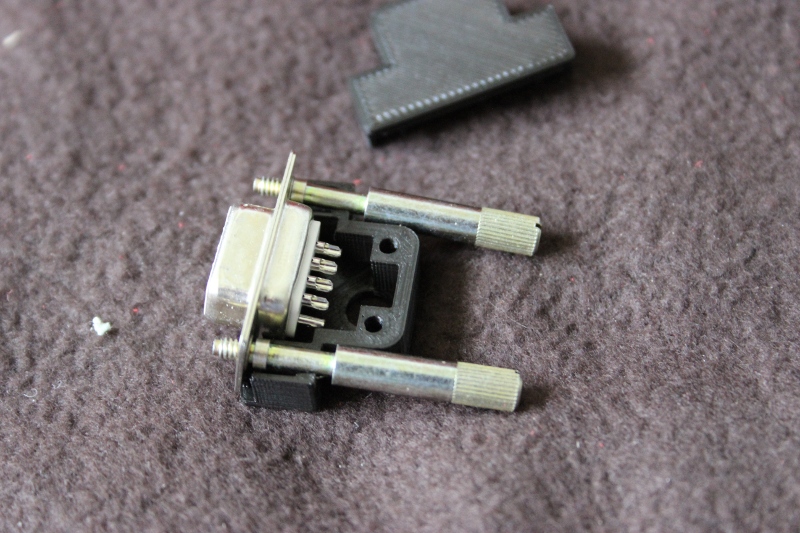

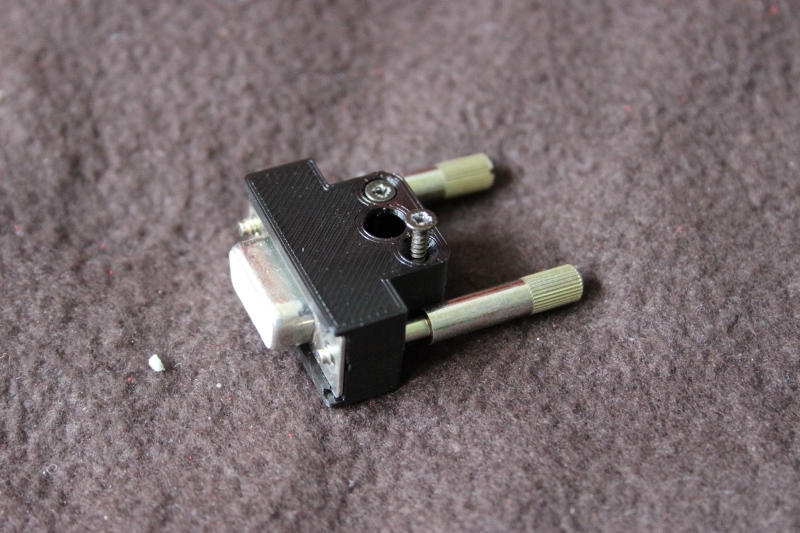

Installation of special covers on the D-sub 9 outlets.

Thank you for your attention and likes to touch me and pushes me to continue the project.

See you soon.

Not a very exciting print but it should come in handy. Modelled up and printed this thing yesterday to show people the difference in infill percentages.

I made the "inserts" removable because you just know people will break the things...

Cool idea and nice execution Robert

My first print with bronzeFill. It's just a small ring I designed for my girlfriend's upcoming fashion show, but boy that filament is awesome. There's absolutely no way you could tell it's printed.

Is that bronze fill ring straight from the printer? it looks slightly rounded, maybe tumbled?

Regardless it's an awesome finish!

Is that bronze fill ring straight from the printer? it looks slightly rounded, maybe tumbled?

Ah, sorry I put the info in the image description, forgot to do so in the post. It was printed at 0.1 layers, sanded lightly and then polished. Didn't take too much time. The rounding happened while sanding, it thought it would give a more realistic metal look. ![]()

Nice. Just did my first perfect print with bronzefill. No more holes, no more material flow at 120-130%. I just need to print fast (50mm/s at least).

Better put some laquer for rings and bracelet if you dont want to end up with a green finger after a few days.

Robert thats a nice print. Great idea too

I've finally finished the character. Paintjob took a little longer than expected ![]() But it came out pretty much as I hoped. Hope it lived up to your expectations as well.

But it came out pretty much as I hoped. Hope it lived up to your expectations as well.

@Valcrow That's an awesome bike, I want to make one too now haha

Wow... Time to lock the thread, it's over.

Blimey! That's set the bar up into the stratosphere.

Very well done Alex.

*droops away*

See you all again in a couple years, when I'm done practicing.

DidierKlein 729

Awesome indeed great job :eek:

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

Top Posters In This Topic

362

282

221

179

Popular Days

Jan 5

30

May 12

26

Jan 13

23

May 1

22

Top Posters In This Topic

ian 362 posts

cloakfiend 282 posts

skint 221 posts

SandervG 179 posts

Popular Days

Jan 5 2014

30 posts

May 12 2014

26 posts

Jan 13 2014

23 posts

May 1 2014

22 posts

Popular Posts

kmanstudios

Took me forever to do this. And it is still rougher than I would have liked. 3D concept rendering: Finished piece:

kmanstudios

I just finished this. It was a multi-part print for ease of painting. Some of it I am not sure what happened...but hey, it is purty....And, I am unanimous in that ? Test Render Parts

gr5

Bath interferometers. I have made about 20 of these for people who use them to test their telescope mirrors. They are amazingly accurate and can do better than a $40,000 Zygo PSI optical tester. Th

Posted Images

valcrow 145

Sneak peak for my UM bros! Printed on the UMO.

Printed on the UMO.

More pics.

http://www.redicubricks.com/3d-printed-ducati-1199-superbike-on-the-ultimaker/

And yes, model is shared on Youmagine.

Link to post

Share on other sites